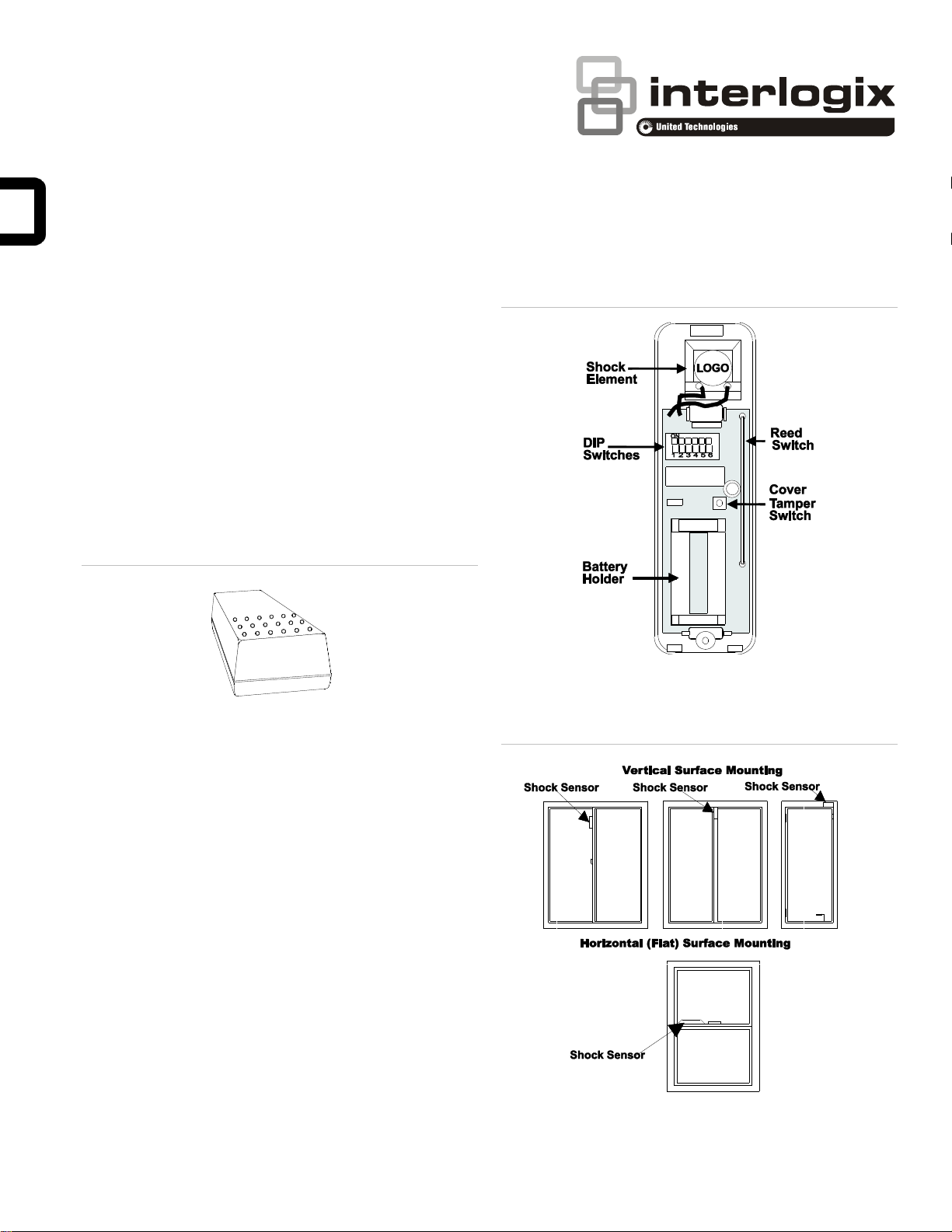

International Shock Sensor Installation Instructions 3

Figure 7: Sensor base mounting holes and magnet alignment

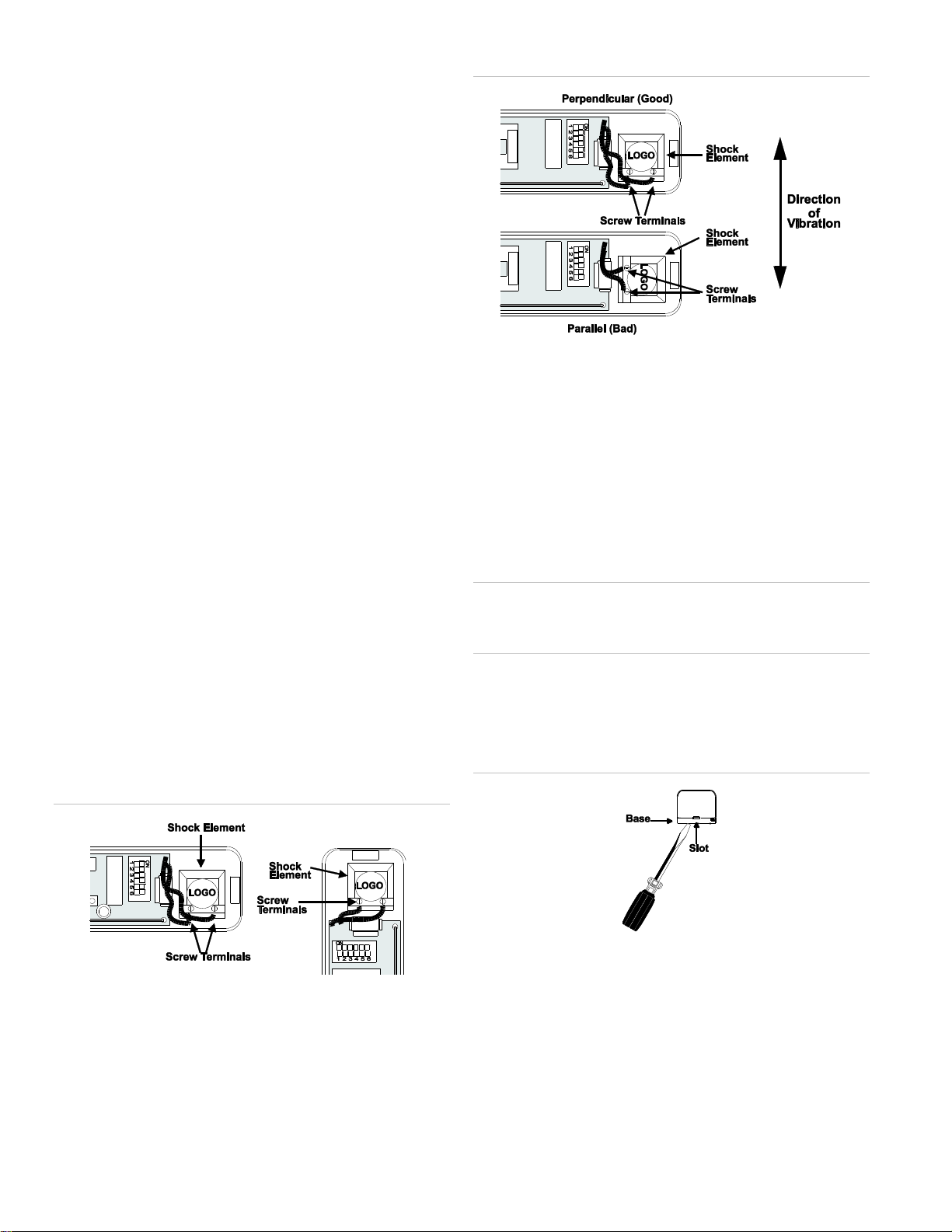

3. Position the shock element and press it firmly into its

socket (see Figure 7 above).

4. If using the reed switch, use the two remaining screws to

mount the magnet so that its arrow is aligned with the

arrow on the sensor case (see Figure 7 above).

Adjusting the shock sensor

The following describes the DIP switch functions:

•DIP Switches 1 and 2—adjust the Pulse Count.

•DIP Switches 3 and 4—adjust the sensitivity setting of

Gross Attack detection.

•DIP Switch 5—enable/disable reed switch.

•DIP Switch 6—not used.

Note: In order for the LED to indicate shock detection while

adjusting the sensitivity, be sure the reed switch is disabled

(DIP switch 5 OFF) or that the magnet is lined up with the reed

switch if DIP switch 5 is ON.

Gross attack adjustment

1. To adjust the sensor for Gross Attack, set DIP switches 1

and 2 to the ON position. This disables the Pulse Count so

that the unit can only be activated by a Gross Attack.

2. Apply high level shocks to the mounting structure, using

the LED as a guide to when the alarm trips (LED on for 4

seconds).

3. The LED will blink for 1 second every time the sensor

detects a pulse. A shock that is severe enough to cause

an alarm will cause the LED to light for approximately 4

seconds.

4. Use switches 3 and 4 to adjust the Gross Attack sensitivity

of the sensor (see Table 1 below).

5. Repeat step 2 each time you make a sensitivity change.

Table 1: Gross attack sensitivity settings

Pulse count adjustment

1. Set the sensor to the desired Pulse Count (see Table 2

below).

2. To test the pulse count setting, generate small shocks on

the mounting structure. Each time a shock is detected, a

pulse is registered in memory and the LED will blink for

one second. If the programmed pulse count is reached

within the most recent 30 seconds, the alarm will trip and

the LED will light for approximately 4 seconds. If the alarm

trips for any reason, the stored pulses are cancelled.

3. Use switches 1 and 2 to adjust the Pulse Count.

Note: Pulse Count signals are counted at 1-second intervals

and stored in a 30-second digital memory. These small signals

can detect an intruder gently prying open a window or door

frame.

Table 2: Pulse count adjustment

System programming

This section describes the basic steps for adding the sensor to

panel memory. Refer to the specific panel documentation for

complete programming details.

1. Enable the reed switch by setting DIP switch 5 to ON. The

reed switch must also be open (no magnet near).

2. With the cover off the sensor, set the panel to program

mode.

3. Proceed to the Learn Sensors menu.

4. Select the appropriate sensor group and sensor number

assignments.

5. When prompted by the panel to trip the sensor, press and

release the cover tamper switch.

6. Exit program mode.