P/N 3101085-EN • REV 006 • ISS 03JUL18 1 / 2

FX-NAC Analog NAC Module

Installation Sheet

Operation

The module is an analog addressable device used to connect a

supervised output circuit to a signal riser. The output wiring is

monitored for open and short circuits. A short circuit causes the

module to inhibit the activation of the audible/visual signal circuit so the

riser is not connected to the wiring fault. Upon command from the

control panel, the module connects the output circuit to the riser input.

The output circuit energizes a riser to operate polarized audible and

visual signals. The module can be used for connection of a Class A or

Class B (with EOL) output notification appliance circuit (NAC).

The device address is set using the two rotary switches located on the

front of the module. One device address is required.

The module is configured to operate as a Genesis

Audible/Visual/Silence device type from the factory. The module can

also be configured for other device types through front panel

programming or the configuration utility. Refer to the applicable control

panel technical reference manual for a list of available device types.

Genesis Audible/Visual/Silence: Used with Genesis and Enhanced

Integrity horns and strobes. Genesis and Enhanced Integrity

appliances maintain synchronization per UL 1971. For Genesis

devices, this configuration allows connected horns to be silenced while

strobes on the same two-wire circuit continue to flash until the panel is

reset.

LED operation

The module provides a bicolor LED that shows its status.

Normal: Green LED flashes

Active: Red LED flashes

Installation

Install and wire this device in accordance with applicable national and

local codes, ordinances, and regulations.

WARNINGS

•This module will not operate without electrical power. As fires

frequently cause power interruption, you should discuss further

safeguards with your local fire protection specialist.

Note: The module is shipped from the factory as an assembled unit; it

contains no user-serviceable parts and should not be disassembled.

To install the module:

1. Verify that all field wiring is free of opens, shorts, and ground

faults.

2. Make all wiring connections as shown in “Wiring”and Figure 3.

3. Set the module address. Refer to the panel technical reference

manual for a list of valid addresses.

Use a screwdriver to adjust the two rotary switches on the front of

the module. Set the TENS rotary switch (0 through 12) for the 10s

and 100s digit and the ONES rotary switch for the 0 through 9

digit. For example: device address 21, set TENS rotary switch to 2

and set the ONES rotary switch to 1 (see Figure 1).

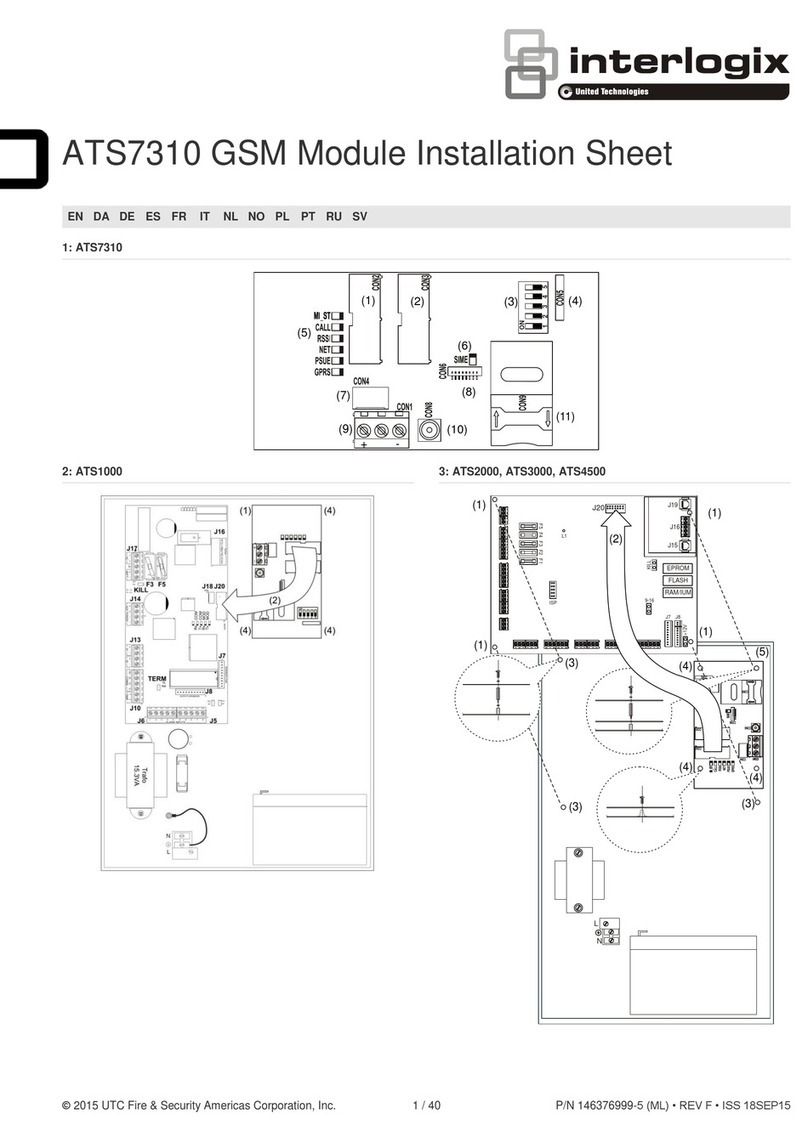

4. Mount the module on the electrical box using screws provided with

the electrical box.

5. Mount the wall plate on the module using #4-24 × 1/2 in. (13 mm)

self-tapping screws.

Figure 1: Module address

Figure 2: Module installation

Wiring

Wire the device as shown in Figure 3. Be sure to observe the polarity

of the wires.

Screw

4-24

screws

Module

Wall plate

Compatible

electrical box