50 Hanover Road, Florham Park, New Jersey 07932 www ascovalve com

Page 2 of 3 I&M No V7569

M INTEN NCE

WARNING: To prevent the possibility of

death, serious injury or property damage, turn off

electrical power, depressurize valve, and vent

fluid to a safe area before servicing the valve.

Cleaning

All solenoid valves should be cleaned periodically. The time between

cleaning will vary depending on the medium and service conditions.

In general, if the voltage to the coil is correct, sluggish valve operation,

e cessive noise, or leakage will indicate that cleaning is required. In

the e treme case, faulty valve operation will occur and the valve may

fail to shift. Clean strainer or filter when cleaning the valve.

Preventive Maintenance

SKeep medium flowing through the valve as free from dirt and

foreign material as possible.

SPeriodic e ercise of the valve should be considered if ambient or

fluid conditions are such that corrosion, elastomer degradation,

fluid contamination build up, or other conditions that could

impede solenoid valve shifting are possible. The actual frequency

of e ercise necessary will depend on specific operating conditions.

A successful operating history is the best indication of a proper

interval between e ercise cycles.

SDepending on the medium and service conditions, periodic

inspection of internal valve parts for damage or e cessive wear is

recommended. Thoroughly clean all parts. If parts are worn or

damaged, install a complete rebuild kit.

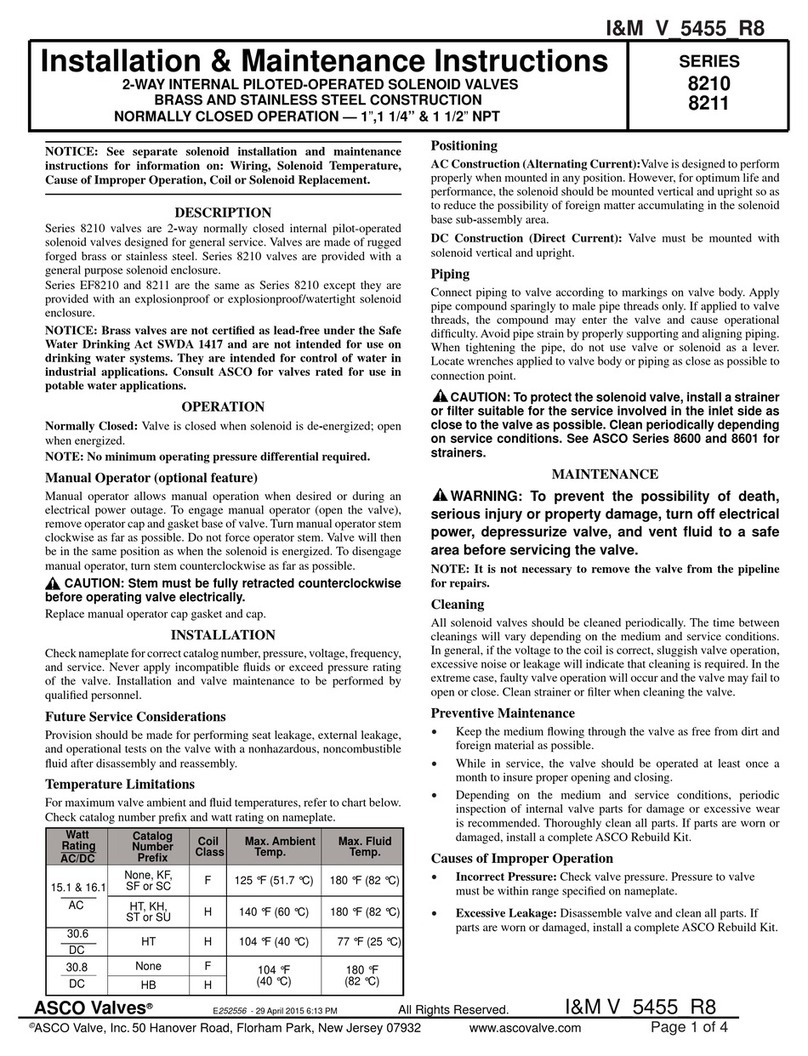

Causes of Improper Operation

SIncorrect Pressure: Check valve pressure. Pressure to valve must

be within range specified on nameplate.

SExcessive Leakage: Disassemble valve and install a complete

ASCO Rebuild Kit.

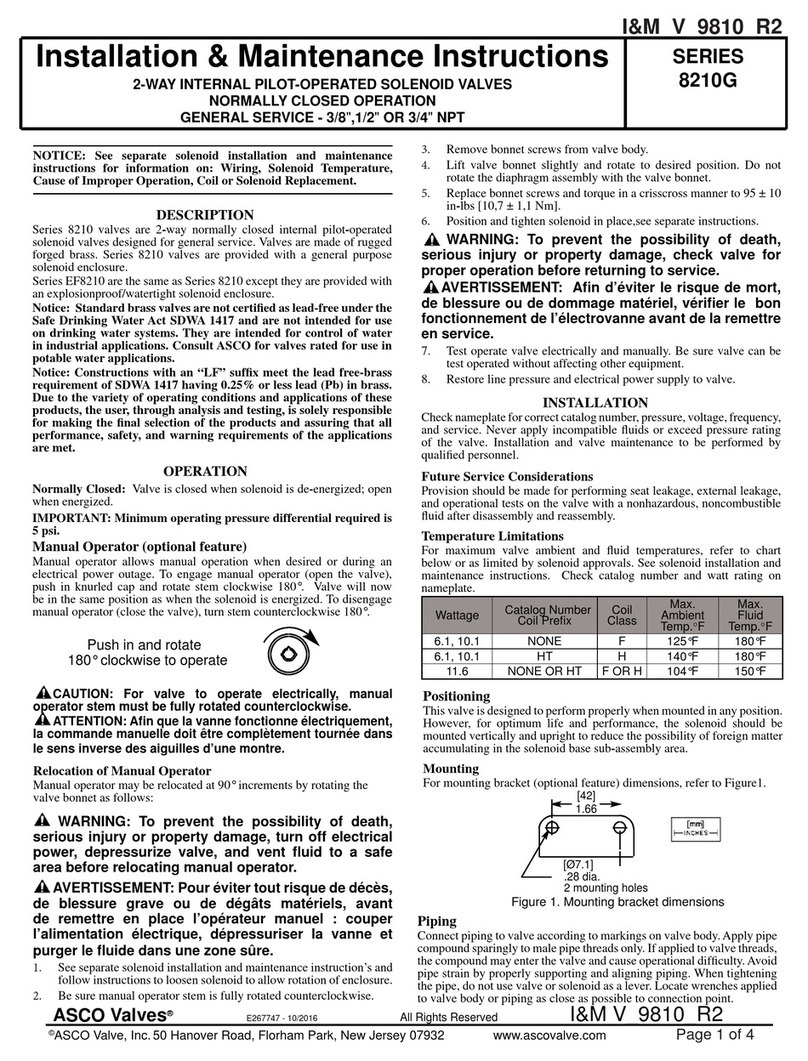

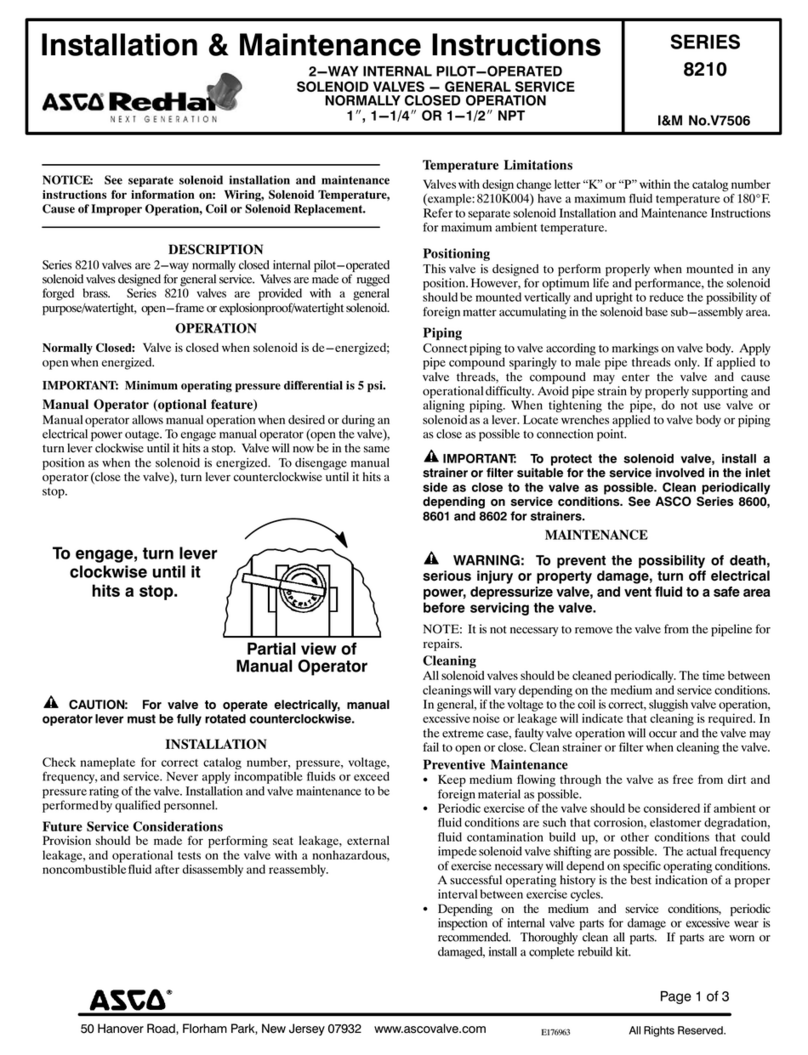

Valve Disassembly (Refer to Figures 2 & 3)

1. Disassemble valve in an orderly fashion using e ploded view for

identification of parts.

2. Disconnect electrical hookup to solenoid and piping to valve

body.

3. Remove solenoid, see separate instructions.

4. Remove two he head mounting screws from offset holes in

valve body using a 5/16I or 8 mm wrench.

5. Unscrew solenoid base sub-assembly from valve body. Then

remove solenoid base gasket and core assembly with core

spring and core guide.

6. Unscrew end cap or optional manual operator and remove disc

holder spring, disc holder assembly and end cap gasket from

valve body.

7. All parts are now accessible for cleaning or replacement. If

parts are worn or damaged, install a complete ASCO Rebuild

Kit.

Valve Reassembly

1. Reassemble valve using e ploded views for identification and

placement of parts.

2. Lubricate all gaskets with DOW CORNINGr 200 Fluid

lubricant or an equivalent high-grade silicone fluid.

NOTE: Solenoid base gasket and end cap gasket are identical.

3. Reinstall end cap gasket, disc holder assembly, disc holder

spring and end cap or optional manual operator in valve body.

Torque end cap to 175 ± 25 in-lbs [19,8 ± 2,8 Nm].

4. Position solenoid base gasket in valve body.

5. Install core assembly with core spring and guide into solenoid

base sub-assembly and engage with valve body.

6. Torque solenoid base sub-assembly to 175 ± 25 in-lbs

[19,8 ± 2,8 Nm].

7. Reinstall valve on actuator, see Mounting Solenoid Valve To

NAMUR Actuator section.

8. Reinstall solenoid and make electrical connections, see

separate instructions.

9. Install piping to valve, see Piping section.

WARNING: To prevent the possibility of death,

serious injury or property damage, check valve for

proper operation before returning to service. Also

perform internal seat and external leakage tests

with a nonhazardous, noncombustible fluid.

10. Restore line pressure and electrical power supply to valve.

11. After maintenance is completed, operate the valve a few times

to be sure of proper operation. A metallic click indicates the

solenoid is operating.

ORDERING INFORM TION

FOR SCO REBUILD KITS

Parts marked with an asterisk (*) in the e ploded view are supplied in

Rebuild Kits. When Ordering Rebuild Kits for ASCO valves, order

the Rebuild Kit number stamped on the valve nameplate. If the

number of the kit is not visible, order by indicating the number of kits

required, and the Catalog Number and Serial Number of the valve(s)

for which they are intended.