2 / 3 P/N 387021P-EN • REV 14 • ISS 14MAR17

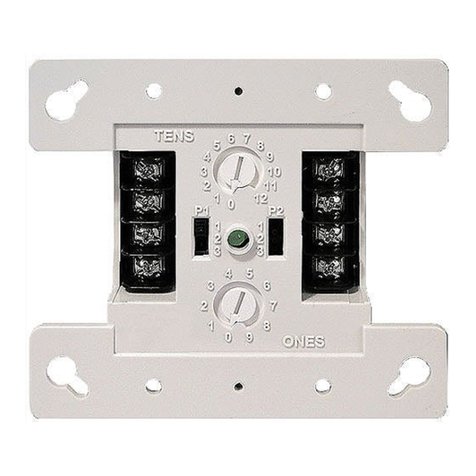

Figure 1: Installing the SIGA-CT1 module

(1) Compatible electrical box

(2) SIGA-CT1 module

(3) Wall plate

(4) #6-32 × 5/8 machine screw

(2X)

(5) #4 × 1/2 self-tapping screw

Wiring

Wire this device in accordance with applicable national and

local codes, ordinances, and regulations.

Notes

• Refer to the Signature loop controller installation sheet for

SLC wiring specifications for additional details.

• All wiring is power-limited and supervised.

• A test resistor is supplied with the SIGA-CT1 to prevent

trouble signals on unused circuits during installation.

When connecting field wires, remove the test resistors and

install a UL/ULC Listed 47 kΩEOLR at the end of the

circuit.

To wire the module:

1. Verify that all field wiring is free of opens, shorts, and

ground faults.

2. Strip 1/4 in. (about 6 mm) from the ends of all wires that

connect to the terminal block of the module.

When stripping wire ends, exposing more wire may cause

a ground fault; exposing less wire may result in a faulty

connection.

3. Make all wiring connections as shown in Figure 2.

Figure 2: Wiring diagram

(1) EOL resistor (PN EOL-47)

(2) 22 kΩresistor for use with

personality code 18

(3) Typical NO initiating device

(4) 10 VDC at 350 µA, max.

(5) Red LED (alarm/active)

(6) Green LED (normal)

(7) Signaling line circuit (from

previous device)

(8) Signaling line circuit (to next

device)

Specifications

Operating voltage 15.20 to 19.95 VDC

Current

Standby

Activated

300 µA

450 µA

Ground fault impedance 10 kΩ

Initiating device circuit (IDC)

EOL resistor value

Circuit resistance

Circuit capacitance

47 kΩ, UL/ULC Listed

50 Ω(25 Ωper wire), max.

0.1 µF max.

Circuit designation

Signaling line circuit

Notification line circuit

Class A, Style 6 or Class B, Style 4

Class B, Style B

Wire sizes 12 to 18 AWG wire (1.0 to 4.0 mm²)

Compatible electrical boxes 2-1/2 in. (64 mm) deep single-gang

box; 4-in. square box 1-1/2 in (38 mm)

deep with single-gang cover

LPCB/CPR electrical box

Requirements

Minimum (W × H × D)

Plastic box with cover plate, no gaps or

unused holes

2.4 × 3.5 × 1.5 in. (60 × 85 × 38 mm)

Operating environment

Temperature

Relative humidity

32 to 120°F (0 to 49°C)

0 to 93% noncondensing

Storage temperature range −4 to 140°F (−20 to 60°C)

(1)

(2) (3)

(4)

(4)

(5)

7

8

12

3

4

++

––

(1)

(3)

(4)

(6)

(8)(7)

(5)

(2)

(4)

(1)

(3)