P a g e | 5

Rev. B

How to Correct Common Failures F-94 and F-49

Why do these errors occur?

These two error codes are interrelated in the sense that the method for correcting them both is

identical. These errors are typically caused by a total power loss to the pump that has forced

the programing to revert back to the manufacturer’s default settings and will require a re-

programing in order to resume normal operation. The key part of the programing that needs to

be reset is the time and date. The following process describes how to accomplish this task

quickly and easily.

Resetting the time and date to correct F-94 & F-49:

1. Plug the unit in and ensure that it is powered off

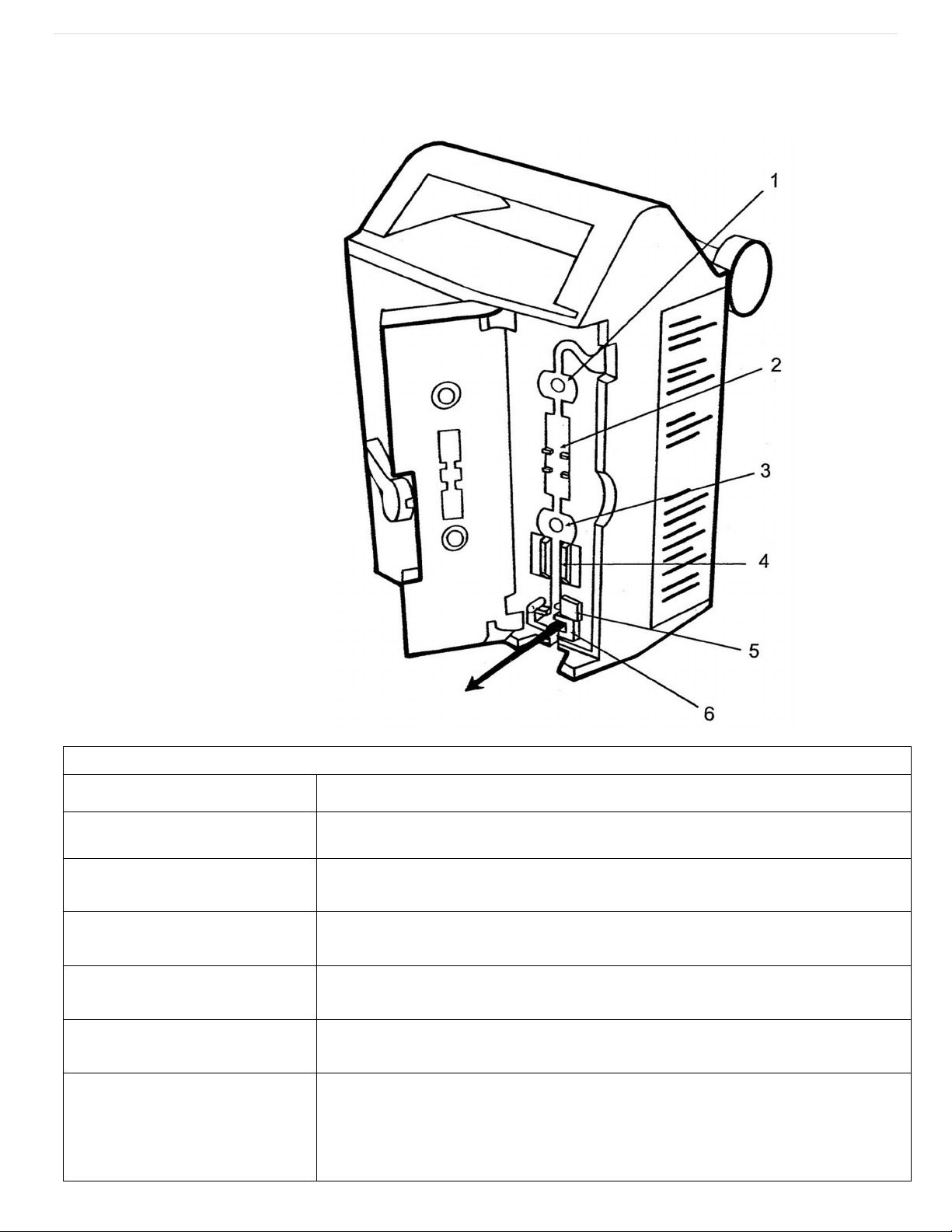

2. On the back side of the pump locate the “Panel Lock Out” button. It will be a small black

push button.

3. Press and hold the “Panel Lock Out” button then turn to the front side of the pump

4. On the front keypad, locate the “Stop” and “On/Off” buttons.

5. While continuing to hold the “Panel lock out button” also press the “Stop” button.

6. With these two buttons pressed and held, tap the “On/Off” button and continue holding

the two previously mentioned buttons.

7. Monitor the top screen of the pump. You are looking for it to say “Modify Config”. Once it

says this you can release the two buttons.

8. Now that you are in the “Modify Config” mode, locate the 3rd key down from the top of

the keypad that says “Tot Vol/ Status” and has the text “Next” lit above it.

9. This key will be used to cycle through the screens of the “Modify Config” mode.

10.Press this key approx. 18 times until you see the top screen say “Time” with some numbers

below it.

11.Don’t worry about what time the pump is currently saying we are now going to program

in the current time at your location in 24 hour or Military format. I.E. if it’s 2:34 pm where

you are then the time you’ll input is 1434.

12.Utilize the number keys to input the current time in the format listed, you’ll see that time

show up in the bottom screen.

13.Once the time is inputted correctly in the bottom screen, press the “Pri Start” key and you

should see the time move from the bottom screen to the top screen.

14.This indicates that your setting has been accepted. If you don’t see this move then you’ll

need to hit the clear button and repeat this process.

15.If you enter a wrong number at this step or the next simply use the “Tot Vol/Status” or

“Next” key to cycle through the menus back around to the option you are trying to

change.

16.After the time is properly inputted, press the “Tot Vol/Status” or “Next” key once more and

the screen should display “Date” followed by numbers for the date.

17.Don’t worry about what date the pump is currently saying. We are now going to program

in the current date in MM/DD/YY format. I.E. if it is Nov. 19th, 2011 we’ll type in 111911.

18.Utilize the number keys again to input the current date in the format listed, You’ll see that

date show up in the bottom screen in the following format: 11 19 2011