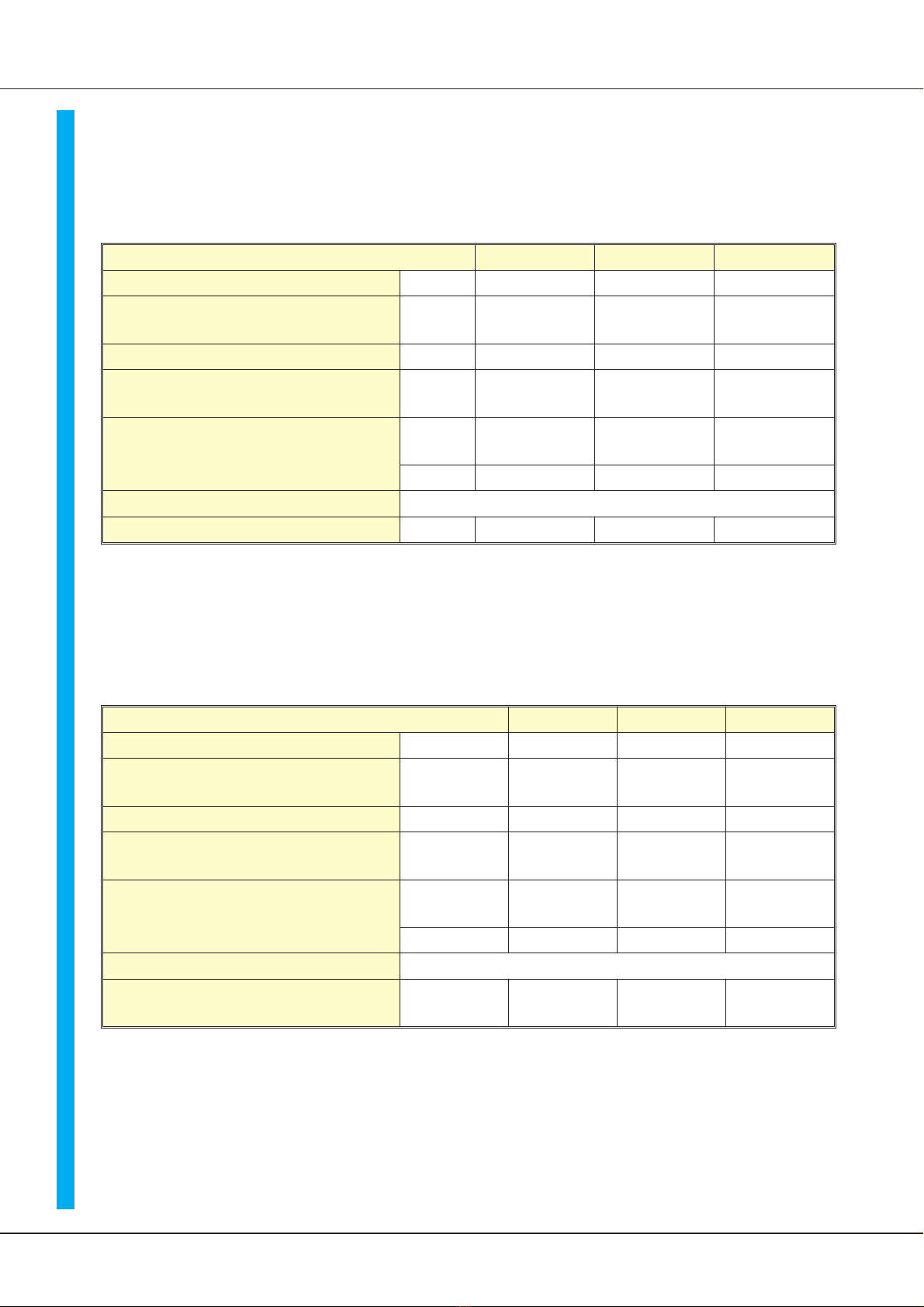

1 Basic information

Q3 1000-2000A 3

Electronic equipment is not fault proof. This fact should be borne in mind for all

possible operating conditions.

Before installation or commissioning begins, this manual must be thoroughly

read and understood by the technical staff involved.

If any uncertainty arises, the manufacturer or dealer should be contacted.

Q3 devices are power electric parts used for regulating energy flow.

Protection rating IP00.

Standards and guidelines

The device and its associated components can only be installed and switched on

where the local regulations and technical standards have been strictly adhered

to:

EU Guidelines 89/392/EWG, 84/528/EWG, 86/663/EWG,

72/23/EWG

EN60204, EN50178, EN60439-1, EN60146,

EN61800-3

IEC/UL IEC364, IEC 664, UL508C, UL840

VDE Regulations VDE100, VDE110, VDE160

TÜV Regulations

Trade body guidelines VGB4

The user must ensure that in the event of:

- device failure

- incorrect operation

- loss of regulation or control

the axis will be safely de-activated.

It must also be ensured that the machine or equipment are fitted with device in-

dependent monitoring and safety features.

Setting adjustments

- should only be carried out by suitably trained personnel

- should only be carried out in accordance with health and safety guidelines

Assembly

- should only be carried out when all voltages have been removed.

QS

Test results are archived with the device serial number by the manufacturer.

CE The device adheres to the following: Guideline EU 89/336/EWG. EMC stan-

Safety advice - Standards and guidelines

ATTENTION - High voltageAC 500V~, DC 650V=

500V

~

ac, 650V=dc