Basic - Information

1Inhaltsverzeichnis

2Basic - Information ........................................................................................................... 2

2.1 Safety advice ...................................................................................................................... 2

2.2 Standards and guidelines: .................................................................................................. 2

2.3 General and features.......................................................................................................... 4

2.4 Technical Data .................................................................................................................... 6

2.5 Specifiation......................................................................................................................... 8

2.6 Interface ............................................................................................................................. 8

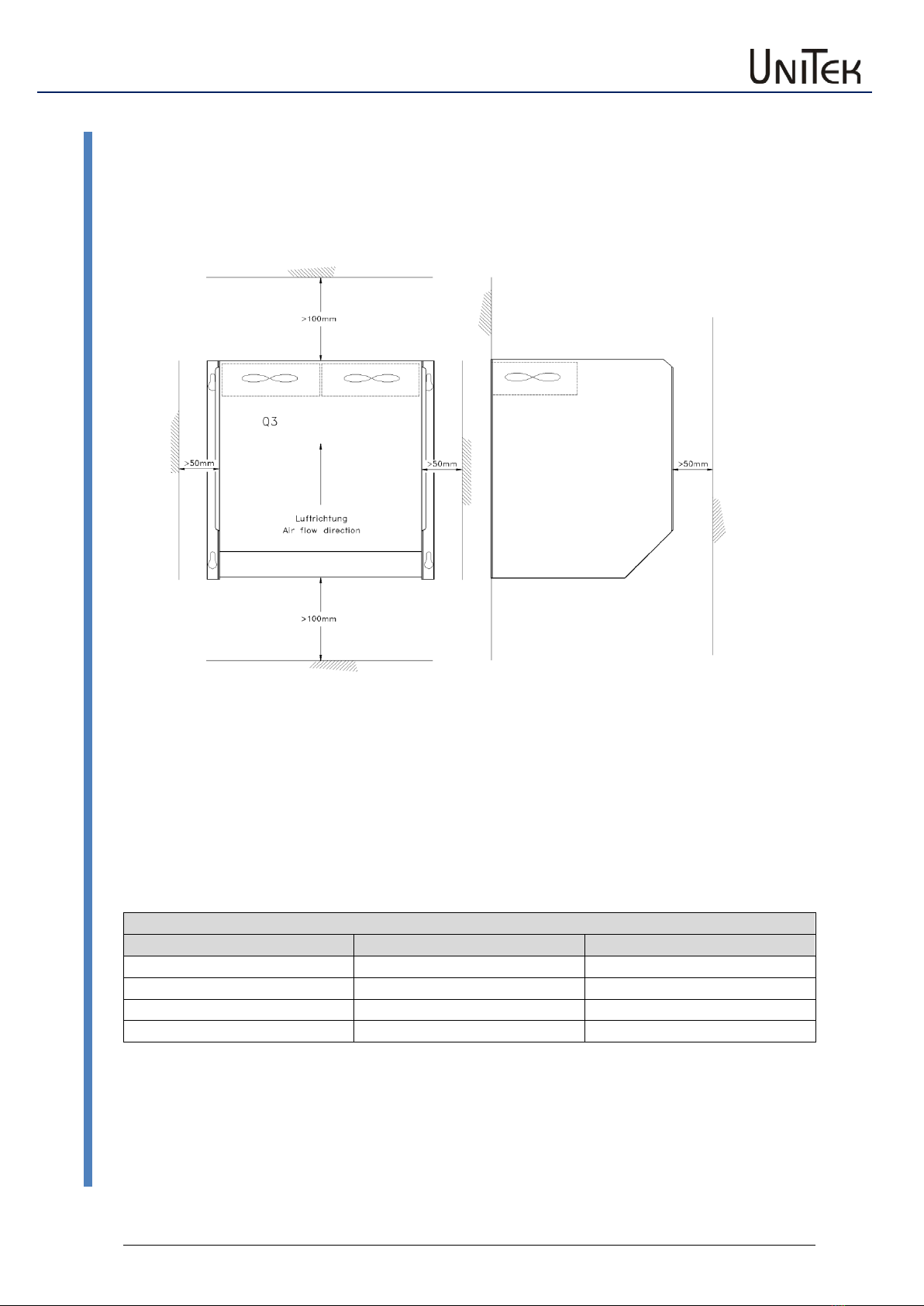

3Mechanical installation .................................................................................................... 9

3.1 Mounting............................................................................................................................ 9

3.2 Dimensions Q3 240-360A................................................................................................. 10

3.3 Dimensions Q3 840A........................................................................................................ 11

3.4 Three-phase power-choke ............................................................................................... 12

4Electrical installation ...................................................................................................... 13

4.1 Connections...................................................................................................................... 13

4.2 Connection diagram ......................................................................................................... 14

4.3 CE-Advice.......................................................................................................................... 15

4.4 Connection advice............................................................................................................ 16

4.5 Power connection ............................................................................................................ 17

4.6 Option............................................................................................................................... 18

4.7 Motor-connection ............................................................................................................ 19

4.8 Field-connection............................................................................................................... 20

4.9 Actual value...................................................................................................................... 21

5Adjustments .................................................................................................................. 22

5.1 Components ..................................................................................................................... 22

5.2 Circuit diagram ................................................................................................................. 23

5.3 Current controller............................................................................................................. 24

5.4 Displays............................................................................................................................. 26

6Commissioning.............................................................................................................. 27

6.1 Commissioning Q3 x/x-x with REG4 ................................................................................. 27

6.2 Protocol Q3 x/x-x with REGxx........................................................................................... 29

7Fauls .............................................................................................................................. 31

7.1 Fauls ................................................................................................................................. 31

7.2 Error diagnosis.................................................................................................................. 32

8Warranty ....................................................................................................................... 33

8.1 Warranty .......................................................................................................................... 33