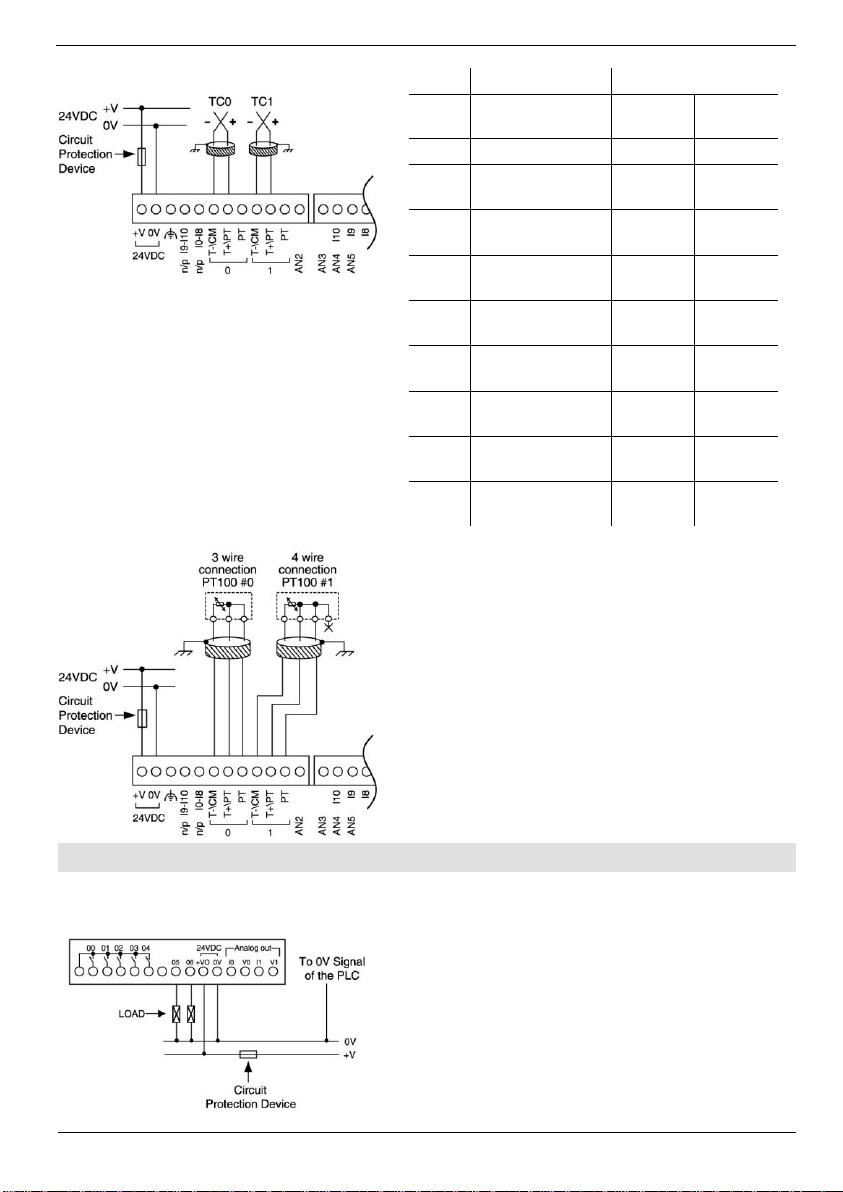

Increasing contact life span

To increase the life span of your contacts & protect the unit from potential damage by reverse-EMF,

connect:

A clamping diode in parallel with each inductive DC load

An RC snubber circuit in parallel with each inductive AC load

The information in this document reflects products at the date of printing. Unitronics reserves the right, subject to all applicable laws, at any time, at its sole

discretion, and without notice, to discontinue or change the features, designs, materials and other specifications of its products, and to either permanently or

temporarily withdraw any of the forgoing from the market.

All information in this document is provided "as is" without warranty of any kind, either expressed or implied, including but not limited to any implied warranties of

merchantability, fitness for a particular purpose, or non-infringement. Unitronics assumes no responsibility for errors or omissions in the information presented in

this document. In no event shall Unitronics be liable for any special, incidental, indirect or consequential damages of any kind, or any damages whatsoever arising

out of or in connection with the use or performance of this information.

The tradenames, trademarks, logos and service marks presented in this document, including their design, are the property of Unitronics (1989) (R"G) Ltd. or other

third parties and you are not permitted to use them without the prior written consent of Unitronics or such third party as may own them