3Phase HF UPS 10-120kva USER Manual

Page2

Contents

Section I: PW series Product System Overview ................................................................................. 3

1.1 Introduction ........................................................................................................................... 3

1.2 PW Series product features .................................................................................................. 4

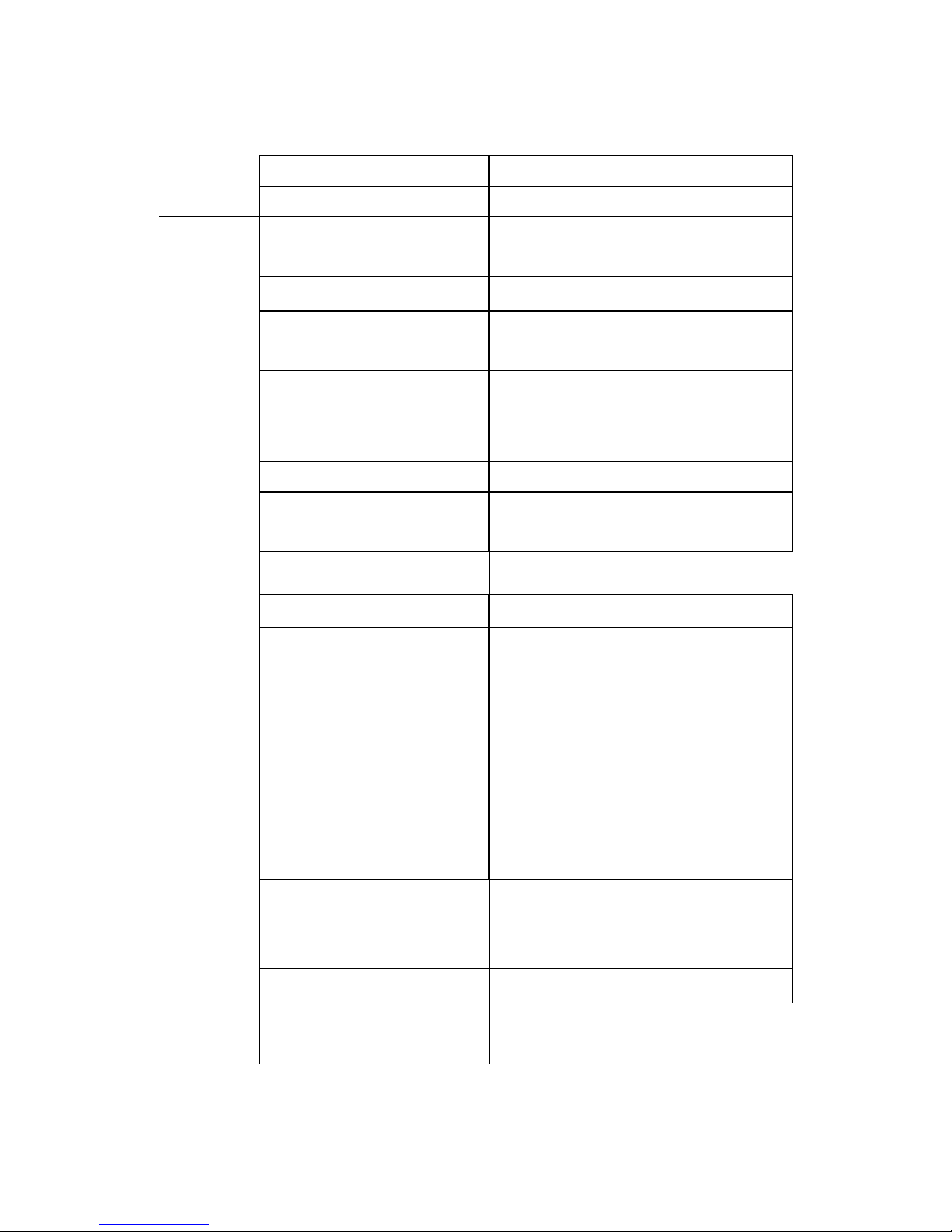

1.2.1 Product specific parameters ........................................................................................ 4

Section II Installation of Single Machine System ............................................................................... 7

2.1 Introduction ........................................................................................................................... 7

2.2 Inspecting and Unpacking the UPS Cabinet ....................................................................... 7

2.3 Storage .................................................................................................................................... 8

2.4 Link (Connection) ................................................................................................................. 8

2.4.1 Incoming mode ............................................................................................................. 9

2.4.2 Power cable ................................................................................................................... 9

2.5 Control cable and communication ..................................................................................... 10

2.5.1 Features of the monitoring panel .............................................................................. 10

2.5.1Input interface of emergency power off .................................................................... 10

2.5.3 Temperature detection interface of the external battery ........................................ 11

2.5.4 Serial port RS232 ....................................................................................................... 12

2.5.5 SNMP card interface .................................................................................................. 12

Section III: Installation of Battery..................................................................................................... 13

3.1 Introduction ......................................................................................................................... 13

3.2 Safety .................................................................................................................................... 13

3.3 Battery cabinet .................................................................................................................... 14

3.3.1 Introduction ............................................................................................................. 14

3.3.2 Environmental temperature ................................................................................... 14

3.3.3 Temperature pickup of battery .............................................................................. 15

3.3.4 Cable incoming ......................................................................................................... 15

3.3.5 Structural map of battery configuration ................................................................ 15

Note: Please pay high attention to the battery connection ,regarding the Negative Pole”-“ ,

the Positive Pole”+” and the Neutral”N”,. ............................................................................ 15

(1) Standard model with internal battery. .................................................................. 15

Please refer the below sketch Diagram 17-1 ...................................................................... 15

3.4 Power cable of battery .......................................................................................................... 16

3.4.1 Installation of battery ................................................................................................ 16

3.4.2 Battery connection .................................................................................................. 17

Section IV Installation of Parallel System ......................................................................................... 17

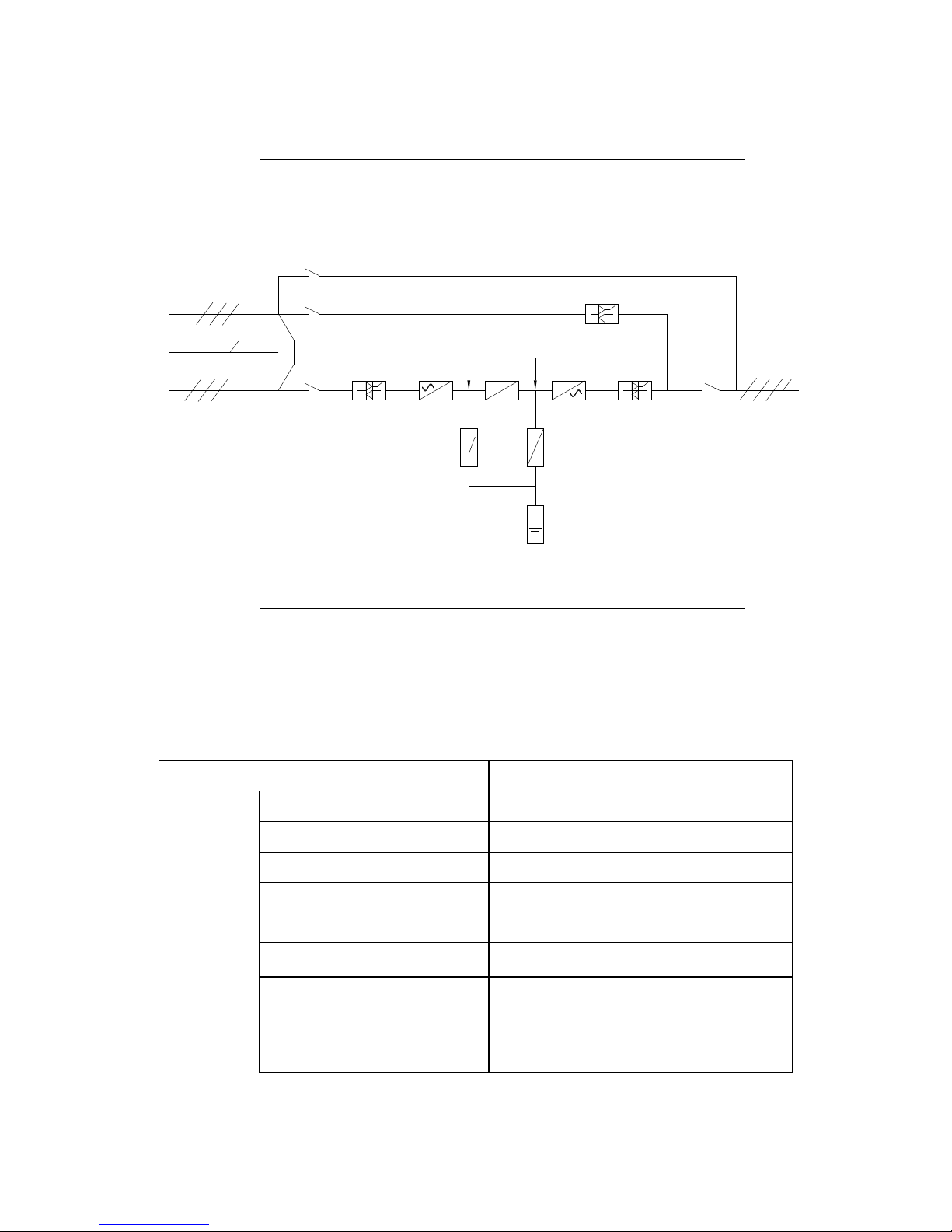

4.1UPS single machine of parallel system ................................................................................ 17

4.2 Hot backup system ................................................................................................................ 19

Section V: Installation Diagram ......................................................................................................... 21

5.1 External structure ................................................................................................................. 21

5.2 Internal view ........................................................................................................................ 21

Section VI: Operation Procedure ...................................................................................................... 23

Section VII: Operational & Controlling Display Panel ................................................................... 25

7.1Introduction ........................................................................................................................... 25

7.1.1 LCD and menu key ................................................................................................. 27

7.1.2 Parameter Setting .................................................................................................... 28