7

Itispossibletocontinuedriving withthepilotlamp“ON”;indoingso,thecoolant

temperatureindicatorshouldbewatchedveryattentively.Itisallowedtoincreasethecoolant

temperatureup to105 °Сmomentary, butnomorethan10 min.

TRANSMISSION

ClutchReleaseControl

YAMZ-236К,YAMZ-238 model’sclutches(mountedonthetruckssuppliedforexport

only) Theclutchisadouble-plate,dry,friction-typeclutchwiththeperipherypositionofcoil

springs. YAMZ-236К, YAMZ-238 model’sclutchesareidenticalindesignanddifferinquantityof

pressurespringsonly.

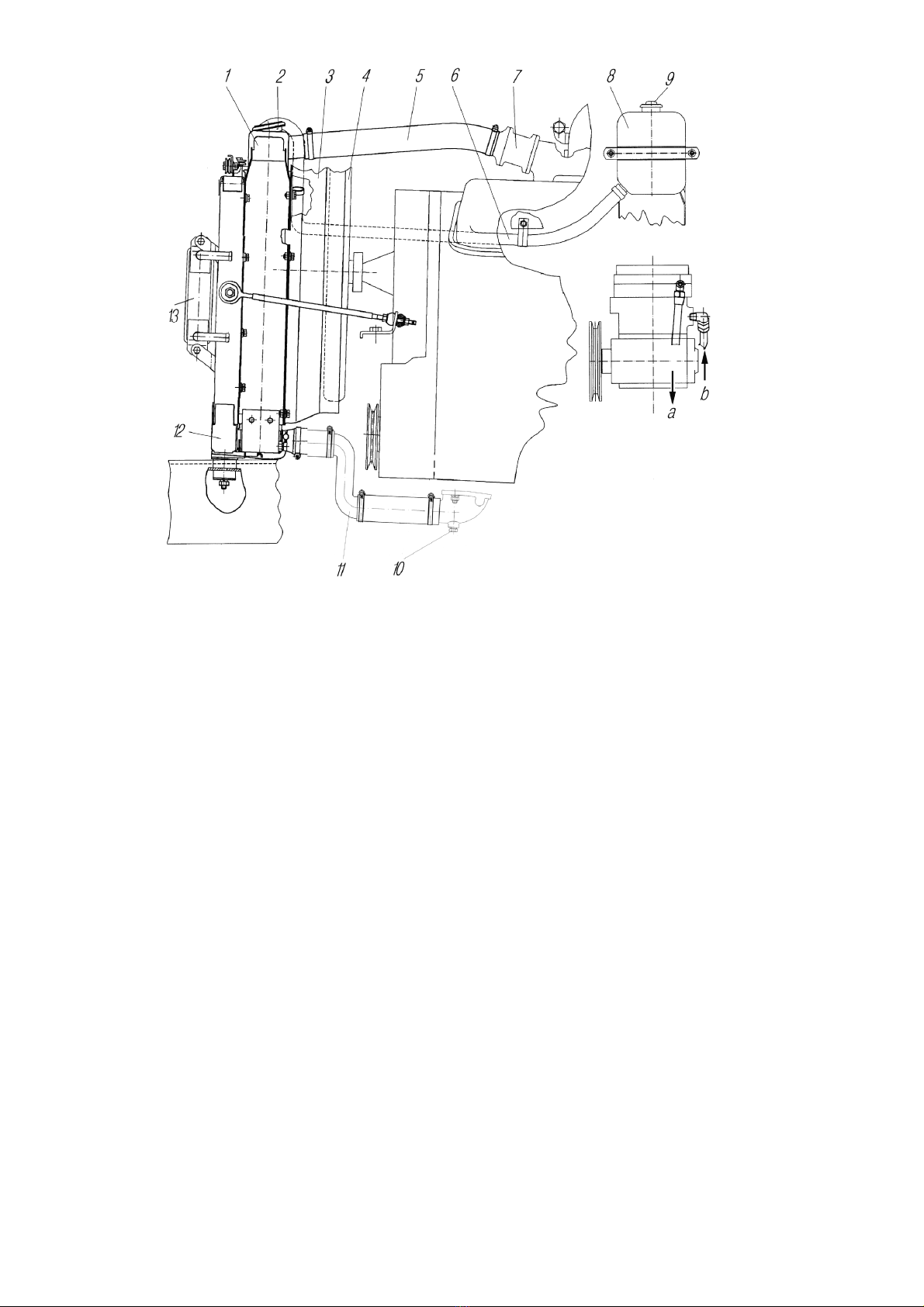

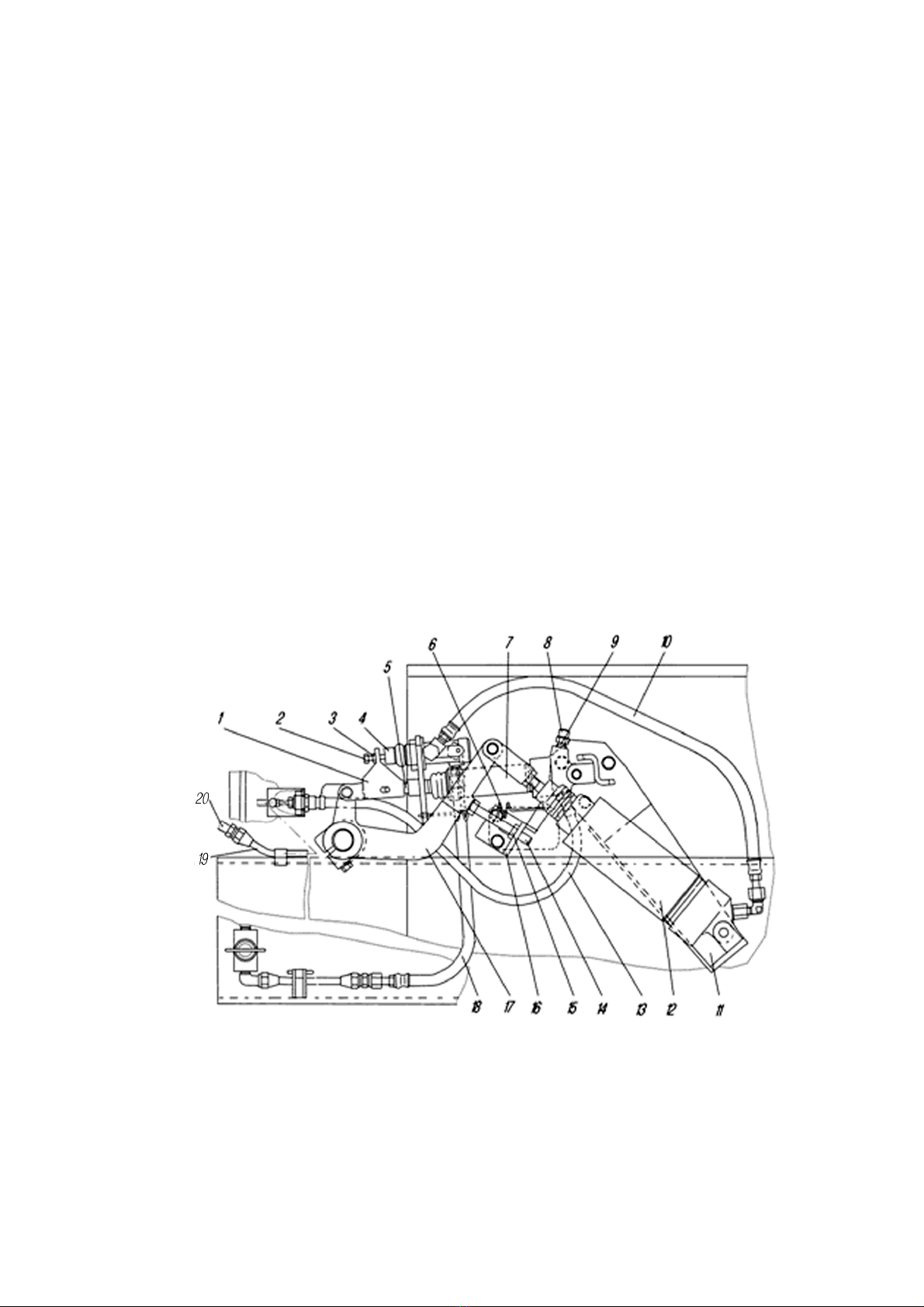

YAMZ-238 clutchcanbedesignedinthesealedversioninaccordance withtheFigure5.

Theclutchcover16 pressedofsheetsteel,withpressureplate19 ready-assembled,ismountedon

theengineflywheel20,andclutchdrivenplates21 aremountedonthesplinedpartofgearbox

inputshaft.Frontandreardrivenplatesarenon-interchangeablepartsandtheyaremountedinthe

specifiedposition,asshowninFigure.Theclutchdrivenplatesareclampedbyaconstanteffortof

coil pressuresprings17 betweentheengineflywheel,middleandpressureplates.YAMZ-236К

clutchhas18 pressuresprings;YAMZ-238 clutchhas20 pressuresprings.Theheat-insulated

spacers18 arelaidunderthespringsfromthepressureplateend.Thepressureandmiddledriving

platesareconnectedwiththeengineflywheelbyfourpins,locatedontheplateoutersurface.The

clutchdrivenplatesintheclampedpositiontransmittheenginetorquetothegearboxinputshaft.

Declutching isperformedbytheclutchreleasecollar 11.Theclutchreleasecollarwiththe

bearing,moving inthedirectionofengine,leadspressureplatefromtheclutchdrivenplate,

transmittingeffortviafourrigiddrawbacklevers5.Theworkingstrokeofclutchreleasecollar

shouldbe–subjecttothefree stroke–nolessthan18,2mm (size “D”).Thefree strokeisadjusted

bytheclutchreleasedevice.Thethrustringofdrawbackleversmovesinthedirectionofgearbox

by27 mmattheexpenseofpermissiblefrictionliningswear.

Thebacklashallowancesbetweentheclutchdrivenplatesandtheengineflywheel’s

frictionsurfaces,themiddledriving andpressureplates,whendeclutching,aresecuredbythe

automaticadjusterofmiddleplatemovementtotheextentoffrictionlining wear.Theautomatic

adjusterconsistsofclutchreleaserods1, fastenedineveryoffourpinsofmiddledriving plate, split

rings2(itisrequiredtoapplythespecifiedeffort,inordertomovetheringsalongtherod),thrust

plates4, whicharefastenedtotheengineflywheelbyboltstogetherwiththeclutchcover, anddisk-

shapedsprings3,mountedontherodbetweenthesplitring 2andthethrustplate4.When

declutching,thepressureplate19 movesbackwardsby2mmminimum,andreleasesreardriven

plate21. Themiddledriving plate22 actuatedbyclutchreleasespring23 alsomovesbackwardsby

thevalueof1,2±0,1 мм,until thesplitring2restsagainstthethrustplate4viaadisk-shaped

spring,andindongsoreleasing thefrontdrivenplate.Totheextentoffrictionlining wear,the

middledrivingplateundertheeffortofpressureplate’spressurespringsmovestotheengine

flywheel; indoingso, thesplitrings2restagainsttheclutchcover,moving alongtheclutchrelease

rods1andretaining asize betweentheringsandthedisk-shapedsprings.Whenmountingthe

clutchwiththeautomaticadjusterofmiddleplatemovementtotheengineflywheel,observethe

followingorder:

1Mountfrontdrivenplate.

2Mountmiddledriving platewiththeclutchreleaserods.

3Mountreardrivenplate.

4Mountthepressureplatewiththeclutchcoverassembly,fasteneditontheengine

flywheelbymeansofeightshortbolts.

5Fitsplitrings2ontotheclutchreleaserods1,untiltheyrestagainsttheclutchcover.

6Fitfourdisk-shapedspringswiththeconvexsidetothesplitrings.