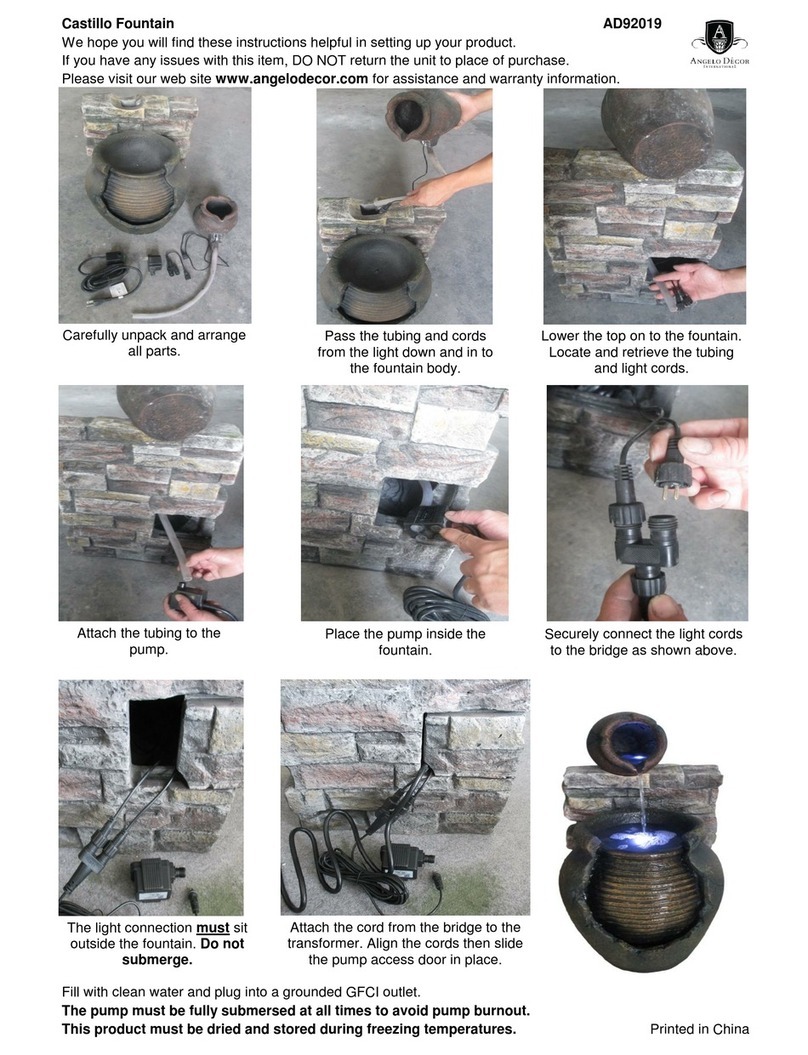

INSTALLATION TROUBLESHOOTING

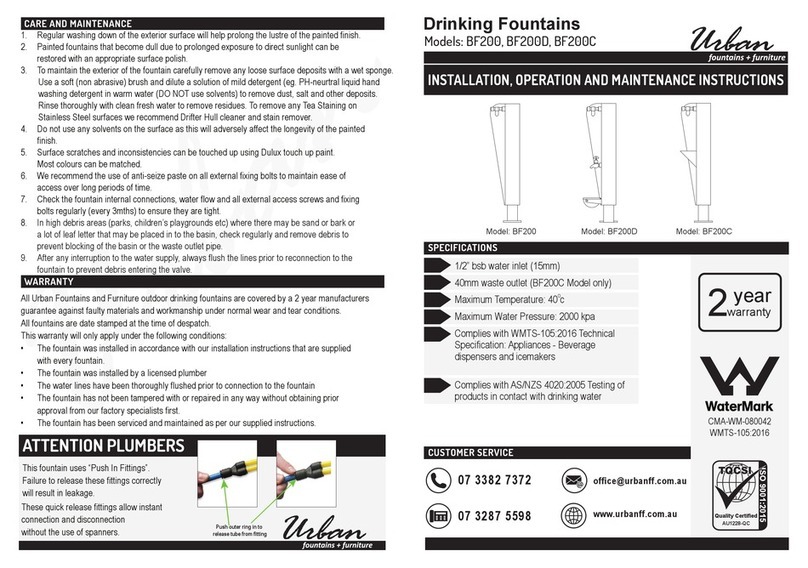

1. All UrbanFF Fountains must be installed by a qualified plumber in accordance with National plumbing and drainage

code AS/NZS 3500.1 and AS/NZS 3500.2 and any local authority codes.

2. Before Installation FLUSH ALL EXTERNAL LINES before connecting to fountain.

3. When mounting the fountain off a wall, check first with a Structural Engineer to ensure it has the capacity to

support this cantilevered fountain. Provide adequate surface for mounting fountain.

4. Remove the fountain from the packaging preventing scratching and damage.

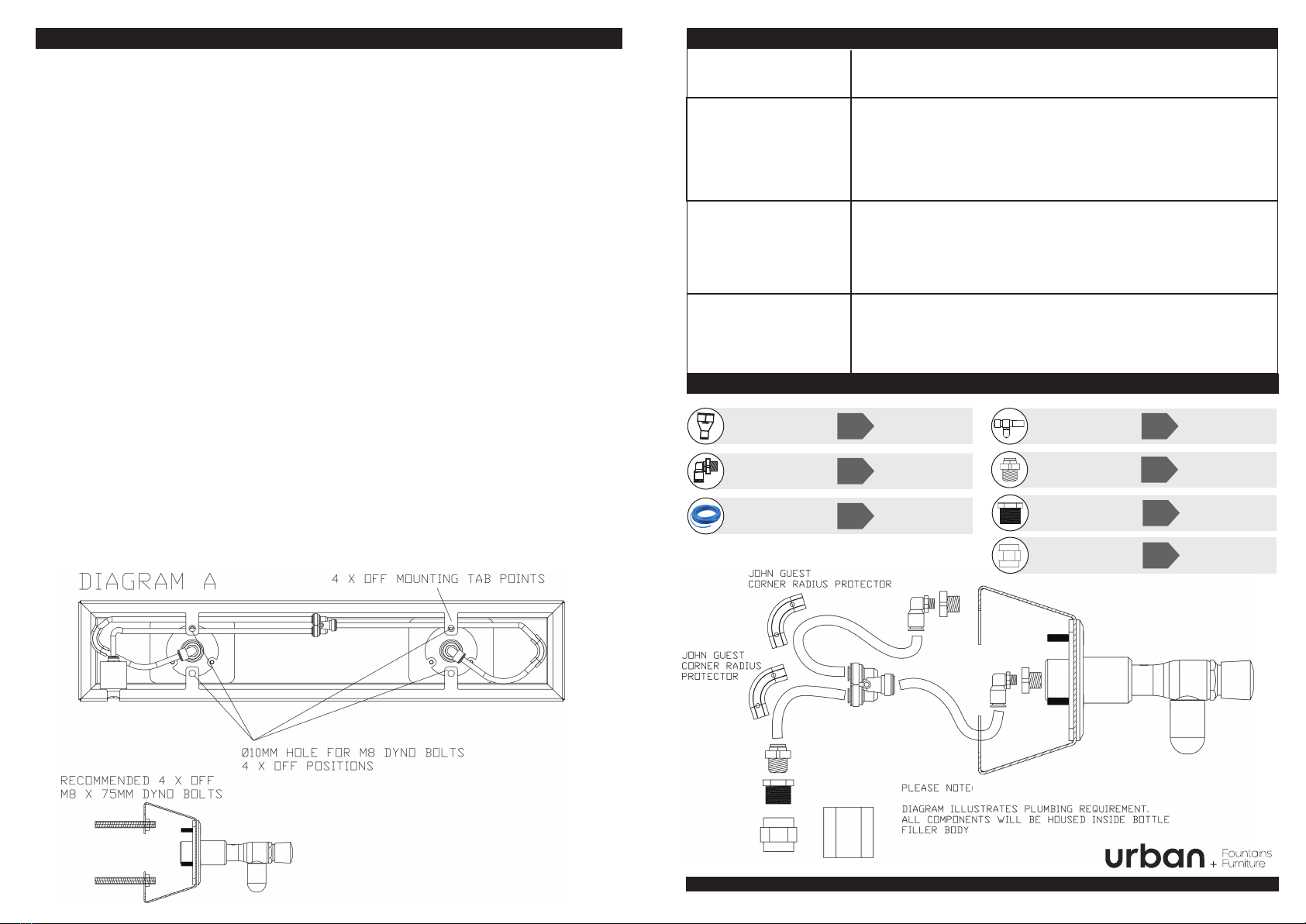

5. Use a standard Metric Allen Key (size 6) for an M6 CSK head screw. Unscrew 3 x off M6 CSK screws from the front

face of the Tap Flange/s. Do this to all instances where there is a tap and flange present, either a 2 tap, 3 tap or 4 tap.

6. Pull the sub assembly of the bottle filler tap and flange forward, in order to gain access into the aperture behind

the flange plate.

7. Present the entire BF200WM bottle filler product, complete with the loose tap and flanges to the wall,

or desired location.Using a permanent marking pen, whilst holding the Bottle Filler Product in the desired installation

location, mark all mounting holes located on the mounting tabs on the back of the bottle filler, to the wall.

8. Remove entire bottle filler product from mounting location and using an 8mm masonry drill, drill holes into wall to

desired depth. * Please note, this is a recommendation, mechanical fasteners may differ by installation

specialist decision.

9. Insert M8 x 75 (or similar) dyna bolts into drilled hole location in the wall.

10. Present complete BF200WM bottle filler product, complete with loose taps and flanges, to the wall and fix to

inserted dynabolt positions.

11. Whilst Bottle filler product is in position on the wall, using a socket wrench with an extension and desired socket size,

present M8 nuts to the M8 dyna bolts and screw up tight. This must be done through the front facing aperture behind

the tap and mount flange, from the front of the bottle filler product.

12. Feed the filler tap and flange back into the aperture on the front of the fountain and use the size 6 Allen key to screw

the flanges back into their original position on the front of the fountain.

13. A certified Plumber must connect the main water supply to the fountain by screwing a standard ½ inch

connection to the provided inlet location on the bottom right-hand side of the bottle filler product.

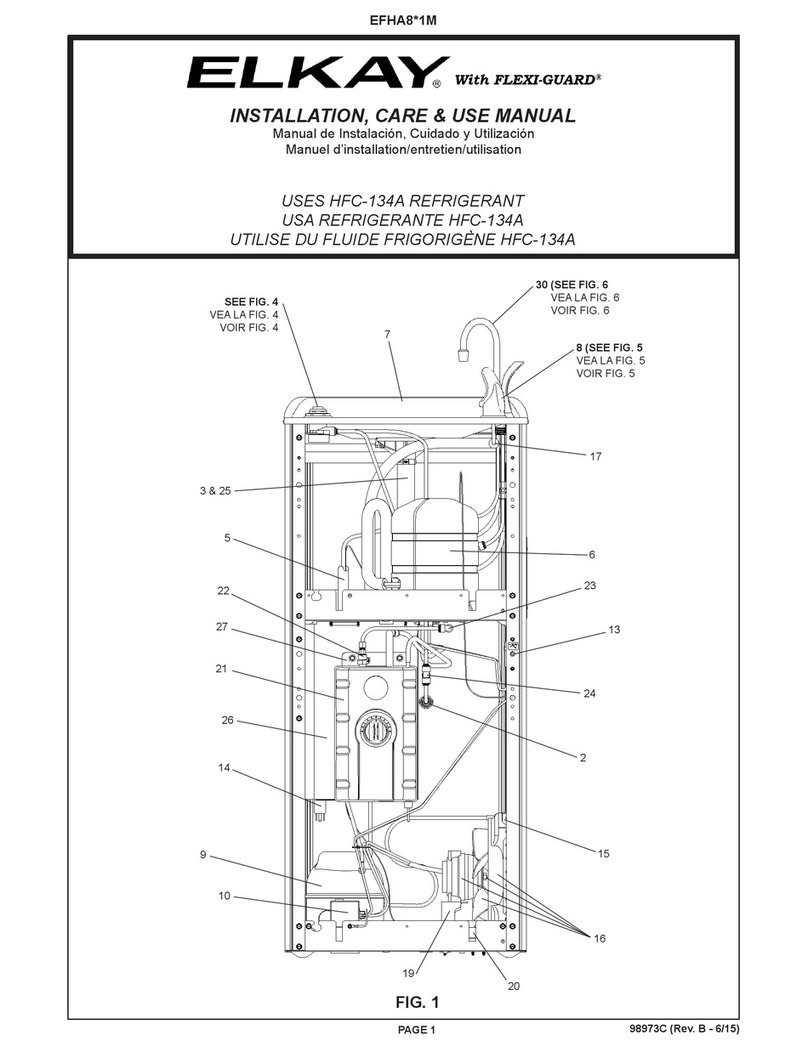

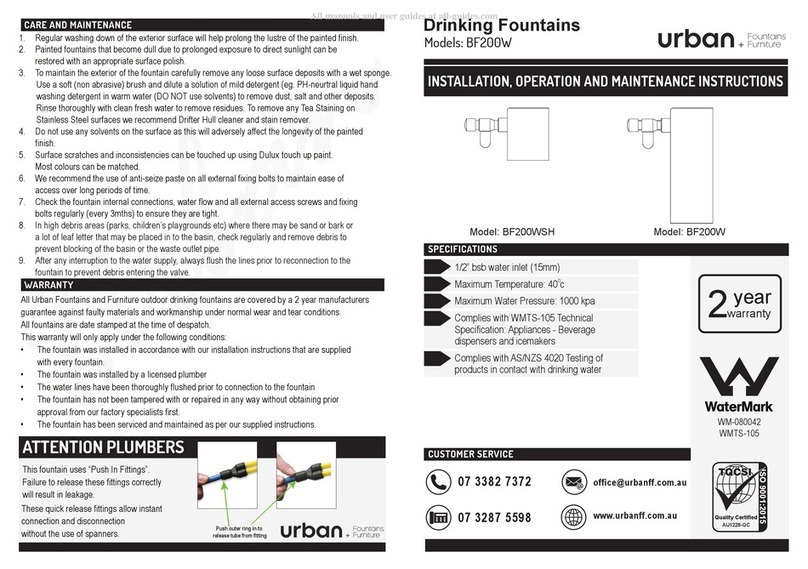

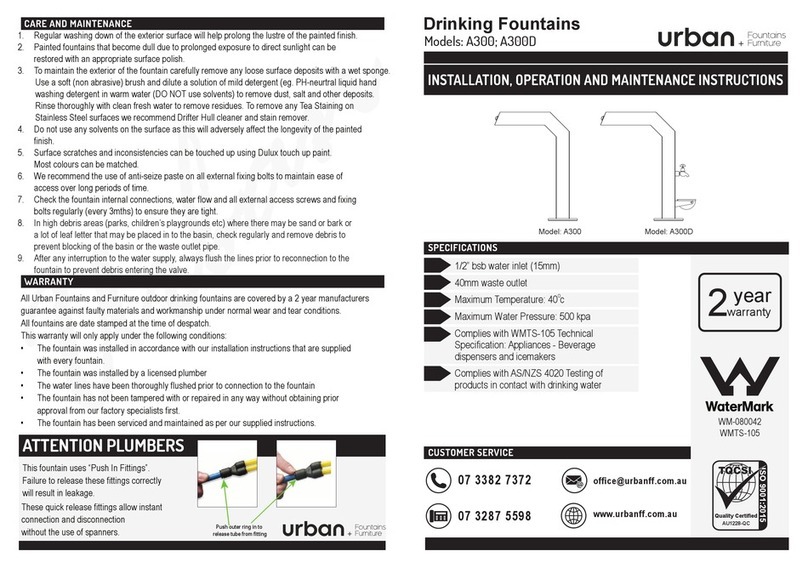

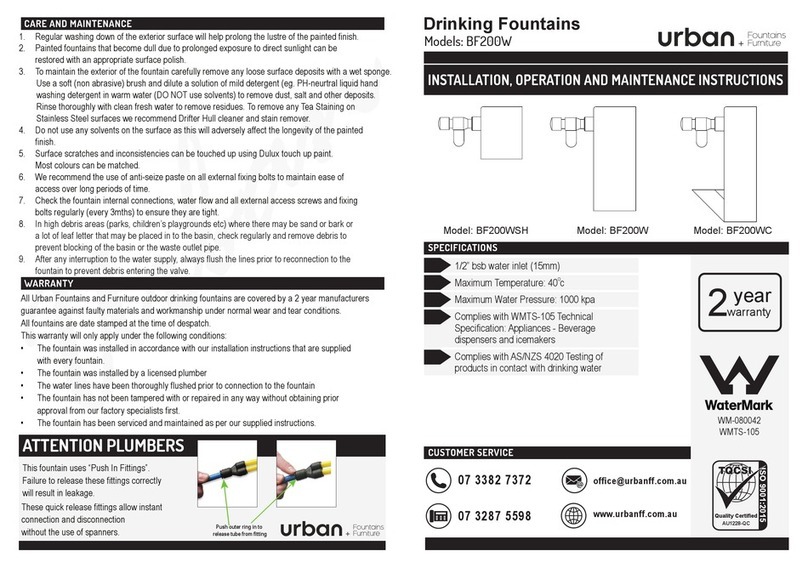

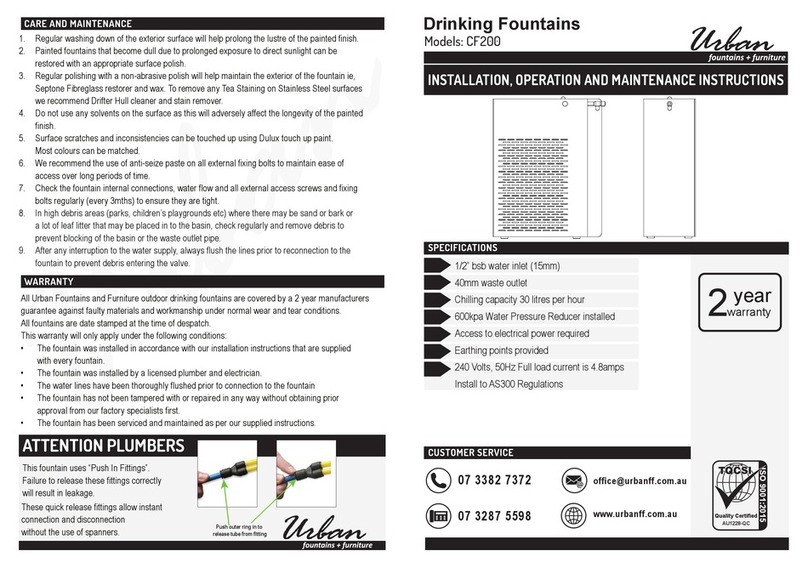

14. Please see below the associated diagrams.

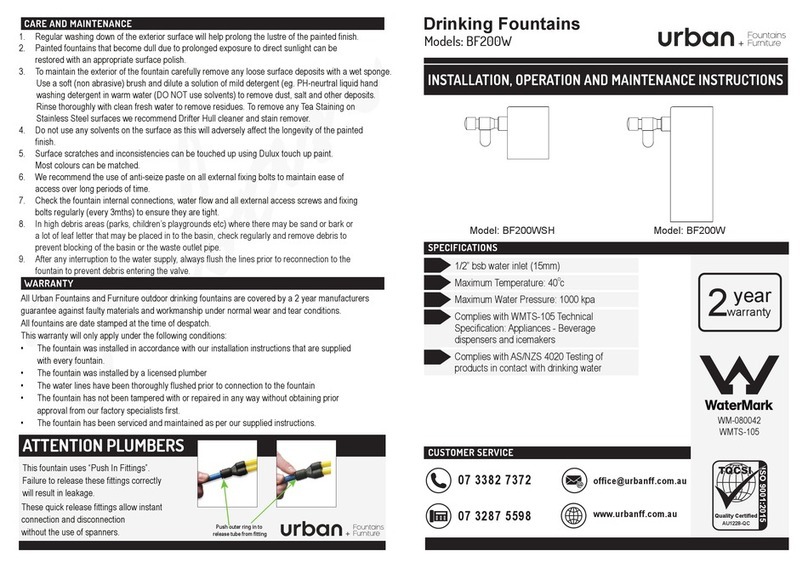

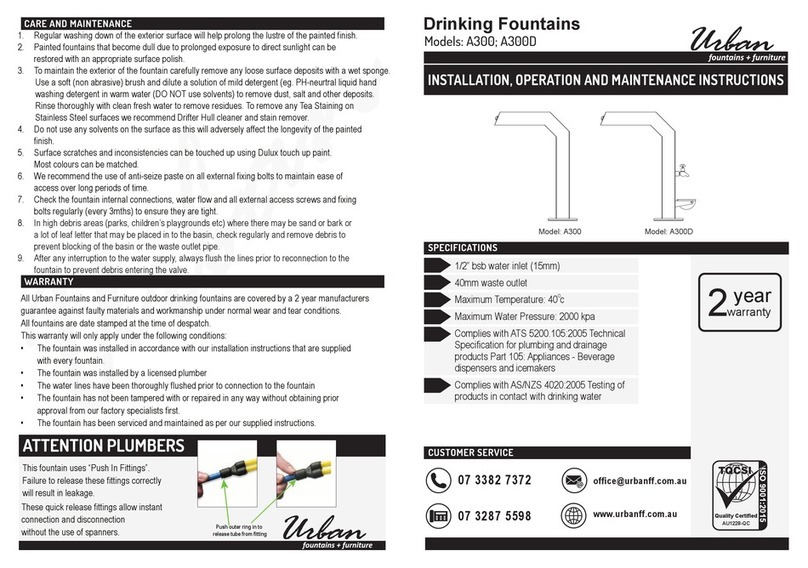

There is restricted or

no water flow?

The water continues

to drip / run after

shutting off?

Leaking from the

internal connections?

The water flow is

shooting over the top of

the basin or is not high

enough and trickling

over the nozzle?

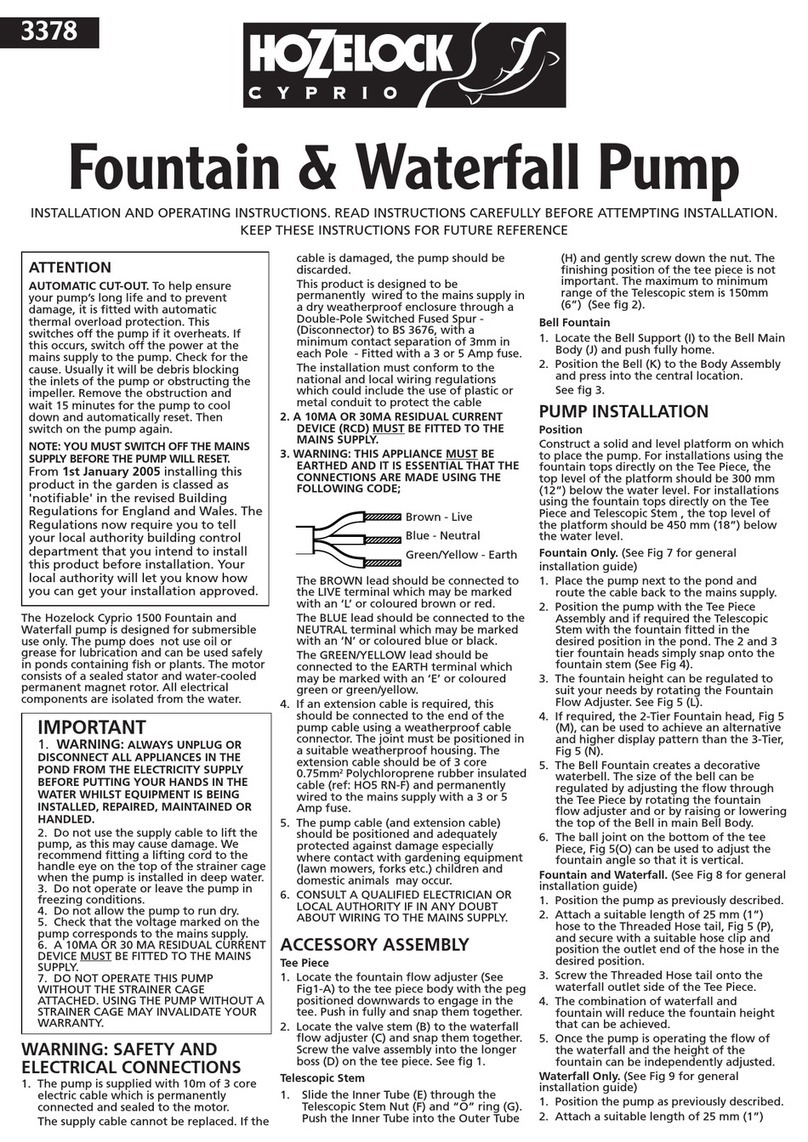

Check the inlet lines for kinks in the tubing. Ensure the water

supply valve is fully open. Check the water pressure regulator is open.

The water pressure is too high / low and needs to be adjusted via the

water flow regulator so it flows in to the catchment area of the basin.

Check that they have been installed correctly. (all fountains are leak

tested prior to leaving the factory). Have the push in fittings been pulled?

(see instructions on how to connect and disconnect push in fittings).

Is the water inlet connection tight?

The most common cause of water not shutting off is a leaking valve and

is due to the lines not being flushed adequately and debris getting in to

the valve through the inlet and sitting on the rubber seals.

To check the valve it will need to be removed. Please contact this office

for details instructions to ensure this is done correctly.

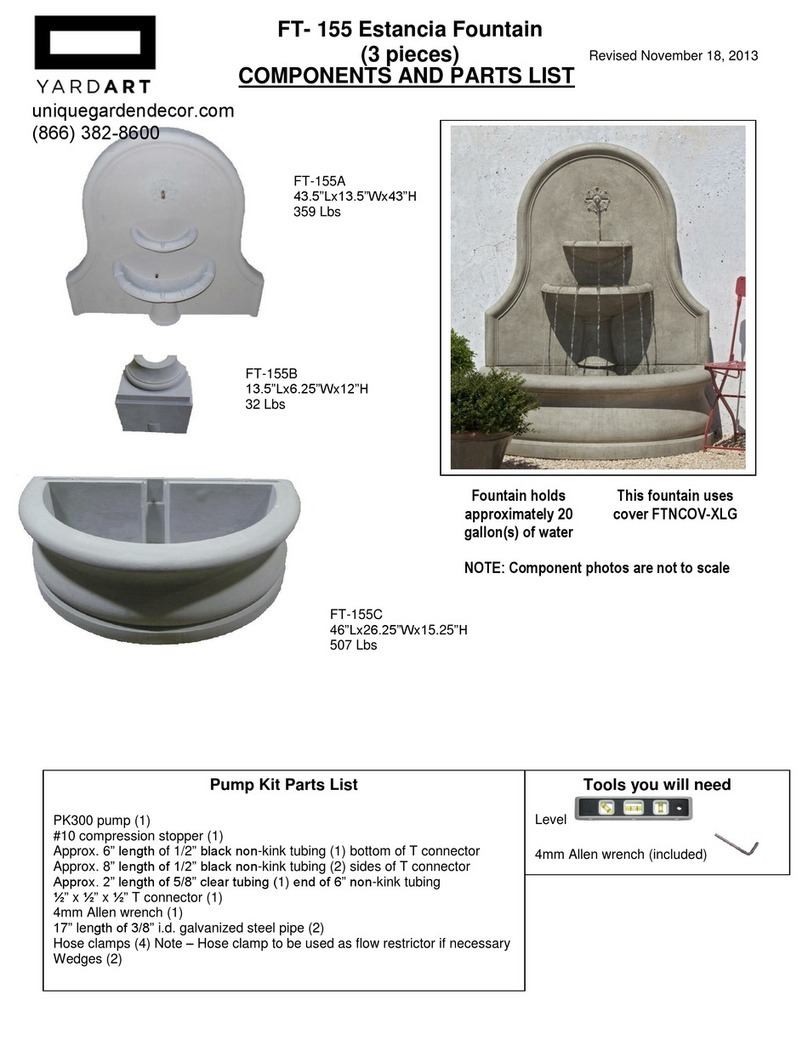

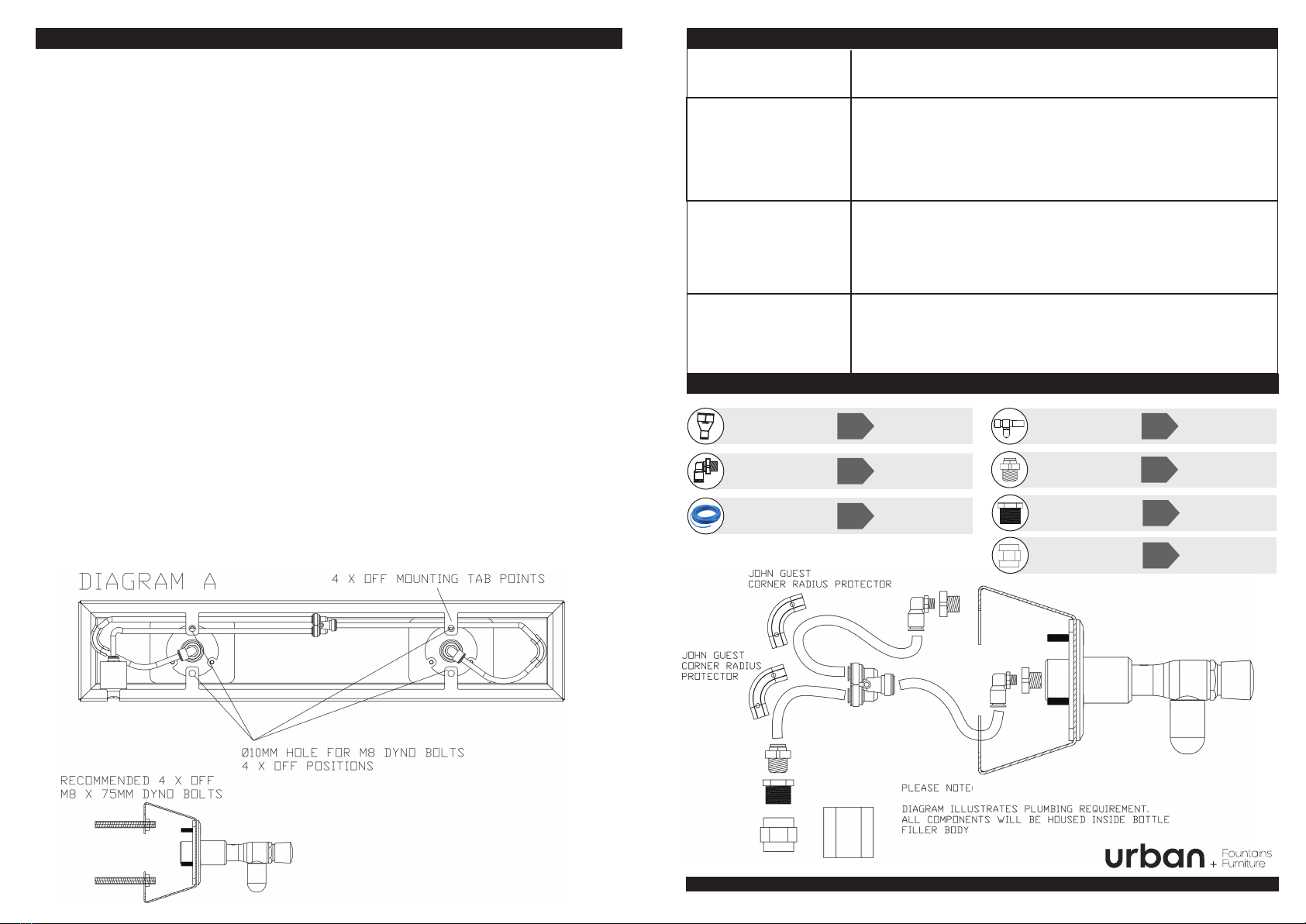

1/4 x 90 Fitting 15-JG8-ELB-1-4X90

15-JG8-YPIECE

reorder

code:

reorder

code:

reorder

code:

reorder

code:

reorder

code:

15-JG8-STR-1-4

Blue Hose 15-HOS-BL8

Y fitting

1/4 Straight

o

SPARE PARTS

reorder

code:

Bottle Filler 15-BUB-TD90P

reorder

code: 15-HOB-1-2-121/2 Reducer

reorder

code: 15-JG8-STR-1-21/2 S/Connector