2

US Shift Transmission Control System instruction and operation manual.

www.USshift.com

Baumann Electronic Controls, LLC.

Phone: (864) 646-8920

Email: support@usshift.com

Address: 207 Mistr Lane, Pickens, SC 29671

This work and the ideas and processes contained herein are the exclusive property of

Baumann Electronic Controls, LLC and may not be copied, reproduced, or distributed in any

form without the express written consent of Baumann Electronic Controls, LLC or Karl

Baumann. The technology and processes contained in this product are proprietary and may be

used only on a single unit basis or as defined by the written permission of Baumann Electronic

Controls, LLC.

vF4.0.0 © Copyright 1997 - 2016 by Baumann Electronic Controls, LLC.

All rights reserved.

WARRANTY

Baumann Electronic Controls, LLC. is dedicated to producing the highest quality

products available in the industry and is committed to customer satisfaction. Because we

have no control over the circumstances under which our products are used, we can

assume no more responsibility for damages (consequential or otherwise) or defects in

materials and workmanship than the original purchase price of our product. Baumann

Electronic Controls, LLC. will repair or replace all defective components unconditionally

for a period of five years from the date of sale. This warranty does not cover damages

due to abuse, improper application, or connection of the device. After the warranty

period, Baumann Electronic Controls, LLC. will service this device for a nominal fee.

APPLICATION COVERAGE

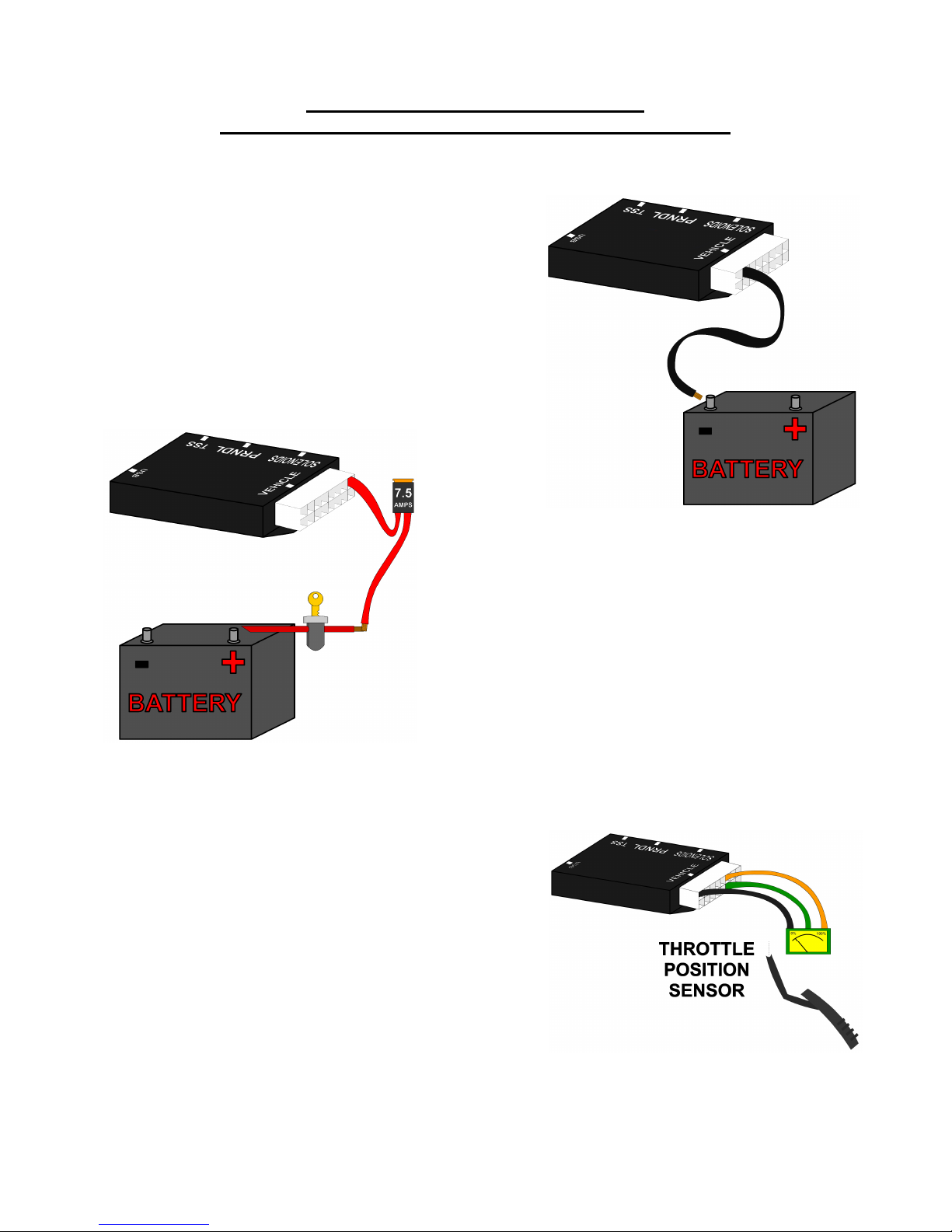

This system works with all 4R70W, 4R75, and AOD-E automatic transmissions. It is

recommended that you use the US Shift wiring harness with this system.