TLD-2500 OPERATING INSTRUCTION MANUAL www.USAIndustries.com | (713) 941-3797

©2022, USA Industries

M-OM-TLD2500-1.1

TLD-2500 TUBE TESTING GUNS

OPERATING INSTRUCTIONS

1. Prior to Testing

⚠

The tubes to be tested should be cleaned and free of any loose deposits or scale. Failure to clean

tubes may cause any materials within the tube to be expelled during the testing procedure and

could cause damage to the test guns and or injury to the operator(s).

⚠

Proper safety equipment should be worn including safety glasses or a face shield to avoid personal

injury when testing with the TLD 2500 Pressure Test Guns.

⚠

Awareness is necessary as to the chemicals used to clean the tube prior to testing to insure seal

material will not deteriorate. Dierent types of rubber, elastomer, or inert seals are available as

substitutes.

⚠

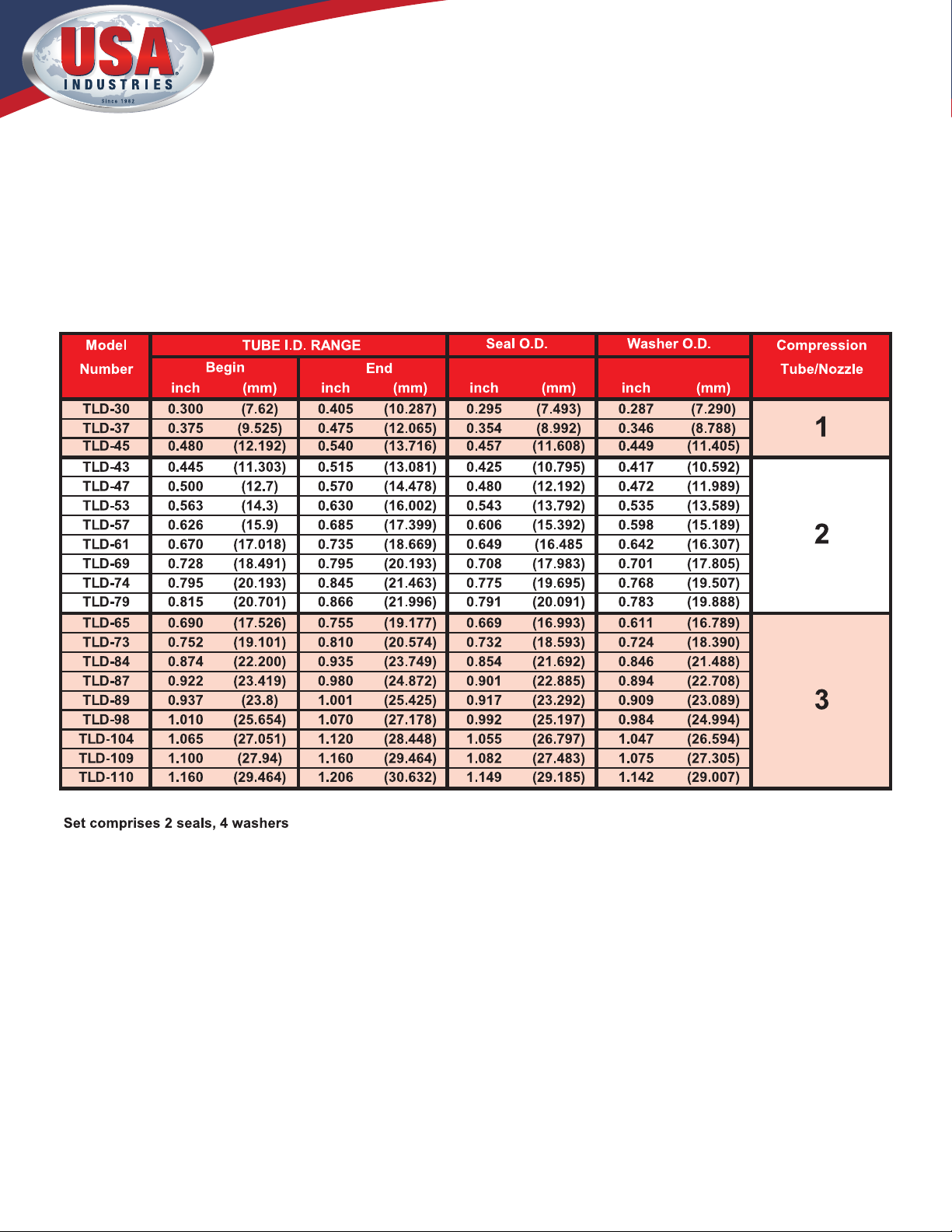

Make sure the test guns have the correct size replacement seal and washer sets and that both are

the correct size for the tubes being tested. Using seals that are too small can cause advanced seal

wear, test gun to stick in tube, or rapid ejection of the test gun from the inside of the tube. Seals

and washers outside diameters are considered correct if nominally 0.02”-0.06” (0.5mm-1.5 mm)

smaller than the tube’s inside diameter.

⚠

Replacement seals for the TLD 2500 Gun can be manufactured for any tube ID from 0.28”-1.23”

(7.1 mm-31.3mm). For tube inside diameters larger than 1.23” contact USA Industries at 1-800-

456-8721.

⚠

The procedure for replacing the seal and washer sets is further explained on page 4.

2. Testing Procedure

1. Never activate the TLD 2500 when inserted into a tube if the seal washers have to be forcefully

pushed to the inside of the tube. Correctly size the seals and washer sets before use. Failure to

do so can result in a stuck gun and/or damaged parts.

2. The TLD 2500 Guns are comprised of a pair, an Air Injection Gun and a Plugging Gun. The Air

Injection Gun is visibly dierent in that it contains an air control valve and a bleed valve. The

Plugging Gun is a companion gun to the Air Injection Gun and will not function without the

injection gun being present.

3. Ax air hose with air supply to Air Injection Gun.

4. USA Industries’ TLD 2500 Test Guns function on air supplies from 40-125 psi (2.7-8.6 Bar) with

a minimum of 5 cubic feet per minute (CFM). These limitations vary due other to pneumatic

tools and units that maybe online within your plant environment. If testing inside diameter tube

dimensions range from 0.28”-0.48” (7.1MM-12.3 mm) a regulator assembly must be attached

and the operating pressures must be kept within 40-60 psi. When installing the regulator

assembly the arrow should be pointed towards the gun and t onto an air hose attached to the

regulator input.