4

SAFETY PRECAUTIONS

WARNING: Please review the following safety precautions before unpacking your new laminator.

• Use care in unpacking and lifting the laminator. Keep laminator level when lifting or moving.

Larger models weigh 60 pounds or more.

• Consider work area. A cluttered work space can lead to accidents. The laminator should be placed on

a level sturdy surface. Do not attempt to operate the laminator in damp or wet environments. Do not

operate electrical devices in the presence of flammable liquids, solvents or in gaseous/explosive

atmospheres. Keep work area well lit. Allow sufficient access to front and back of machine. See the

manual for additional work space requirements.

• Respect feed rollers. Keep hands away from feed rollers and any other moving parts. Turn drive

switch OFF before attempting to clear film wrap-arounds or jams. Use reverse feature to clear film.

Do not wear any loose clothing, ties, jewelry, etc., which can be caught by feed rollers and draw any

body part into the machine.

• Respect heat shoes. Operating temperatures are hot enough to burn skin. If clearing a film wrap-

around or jam on or near heat shoes, first turn the heat switch OFF and allow laminator to cool to

room temperature. If your laminator is equipped with a heat shoe guard, do not operate without this

guard in place.

• Watch out for cutter blade at rear of laminator. Blade is extremely sharp.

• Do not operate laminator with any panels or guards removed. Panels and guards protect

operators from such moving parts as the drive chain and sprockets, roller ends, etc.

• Turn the drive switch OFF before walking away or leaving the laminator unattended.

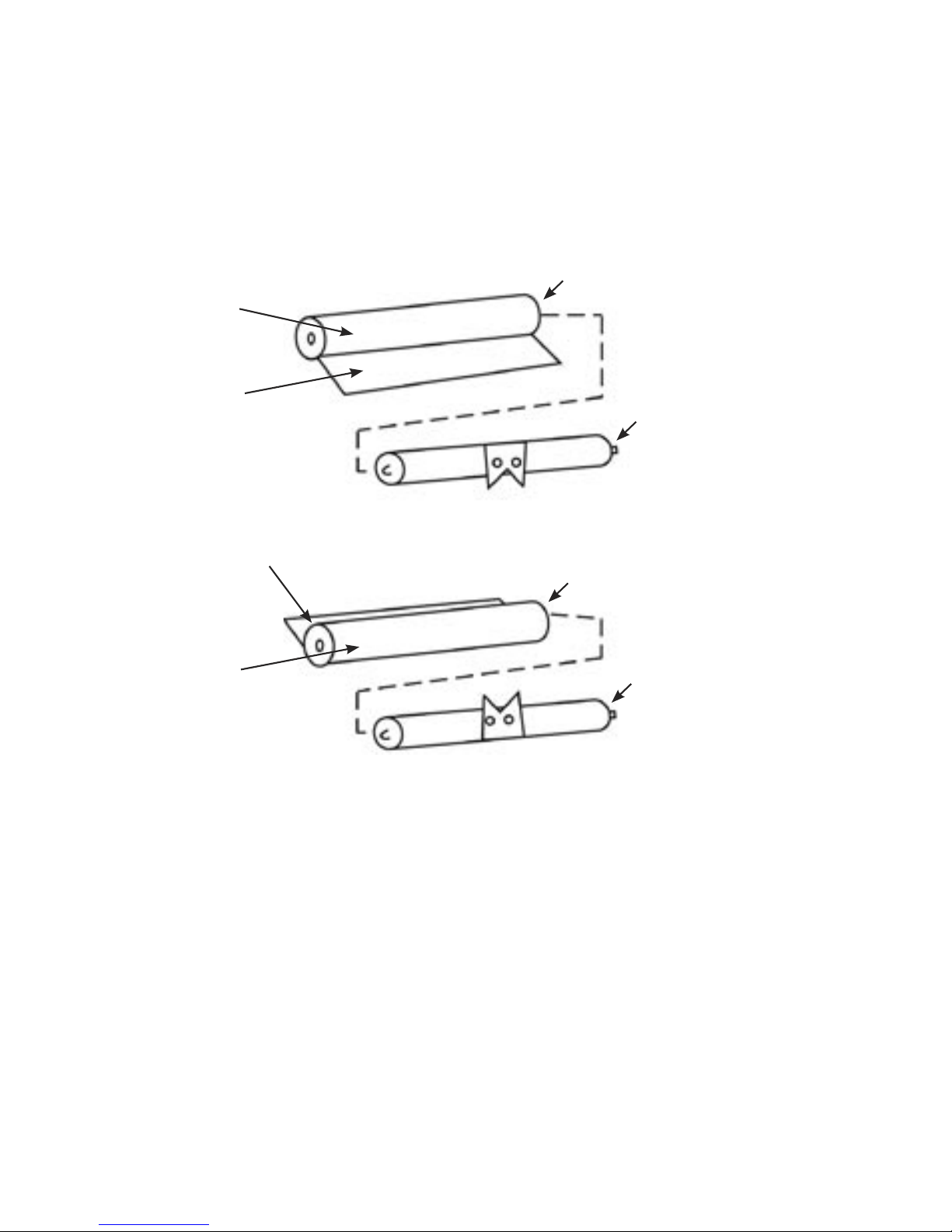

• Before lifting or moving laminator, turn drive switch OFF, turn heat switch OFF, unplug unit and allow

to cool to room temperature. Remove film rolls before lifting or moving machine. Film is easy to

rethread, see the section in this manual.

• Keep children away. Make sure visitors are kept well back from an operating laminator.

• Do not abuse electrical cord. Never pull cord to disconnect it from a receptacle. Do not allow cord

to contact heat, oil or sharp edges. Do not cut off or otherwise bypass the grounding prong on the plug.

• If an extension cord is necessary be sure it is properly rated and of atleast the same wire gauge or smaller

as the laminator cord. Capacity of the cord must prevent loss of power and overheating. Before using,

inspect extension cord for any damage, including loose or exposed wires, broken fittings, damaged

insulation, etc.

• If you service the laminator yourself, call USI’s Technical Assistance department (1-800-752-9131)

for additional safety recommendations. Use only USI parts for service or replacement.

Failure to use USI parts could void manufacturer’s warranty. Note: Always turn laminator off and unplug

before servicing.

• Use common sense. Be cautious when operating your laminator. Do not operate laminator when

you are tired or your reactions are impaired in any way.

• Do not allow anyone to operate the laminator who has not received proper instruction and has not

read the safety instructions.

LAMINATOR INTRODUCTION

USI roll laminators are uniquely designed and engineered to be user friendly, reliable and virtually trouble free. USI’s

modular construction makes them easy to maintain and repair. All equipment controls are basic in design, functional

and positioned for easy access.