45-8447

Recalibration of the Utica Adjustable Torque Screwdrivers

Proper calibration equipment is required to ensure accuracy!

Check the screwdriver on the torque tester to compare the readings of the tester to the desired setting of the1. screwdriver.

To make adjustments, loosen the setscrew with a .035” hex key. With the right thumb and forenger, turn the2. adjusting screw in a counterclockwise direction until it stops. Then in a clockwise direction, turn it one full

revolution.

Attach the screwdriver to the torque tester with a 1/16” hex key. Adjust screw clockwise or counterclockwise to3. obtain a reading of approximately 10 in-oz on the torque tester when actuating the screwdriver.

The torque setting should now be made by turning the adjusting screw clockwise (right hand) to increase the4. torque value and counterclockwise to decrease the torque value. Actuate the screwdriver on the tester drive

and observe the readings of each revolution. Continue adjustments and checking until the desired setting is

achieved.

Note: In some cases if may be necessary to make an additional small adjustment to the adjusting screw. Refer

to Step 3.

Tighten the setscrew to lock the adjusting screw.5.

Note: This torque screwdriver is a precision instrument and should be carefully handled, used and stored. If the unit

is dropped or subjected to abnormal handling or impact it should be checked on a Torque Tester before using.

Utica®

Torque Limiting Screwdrivers

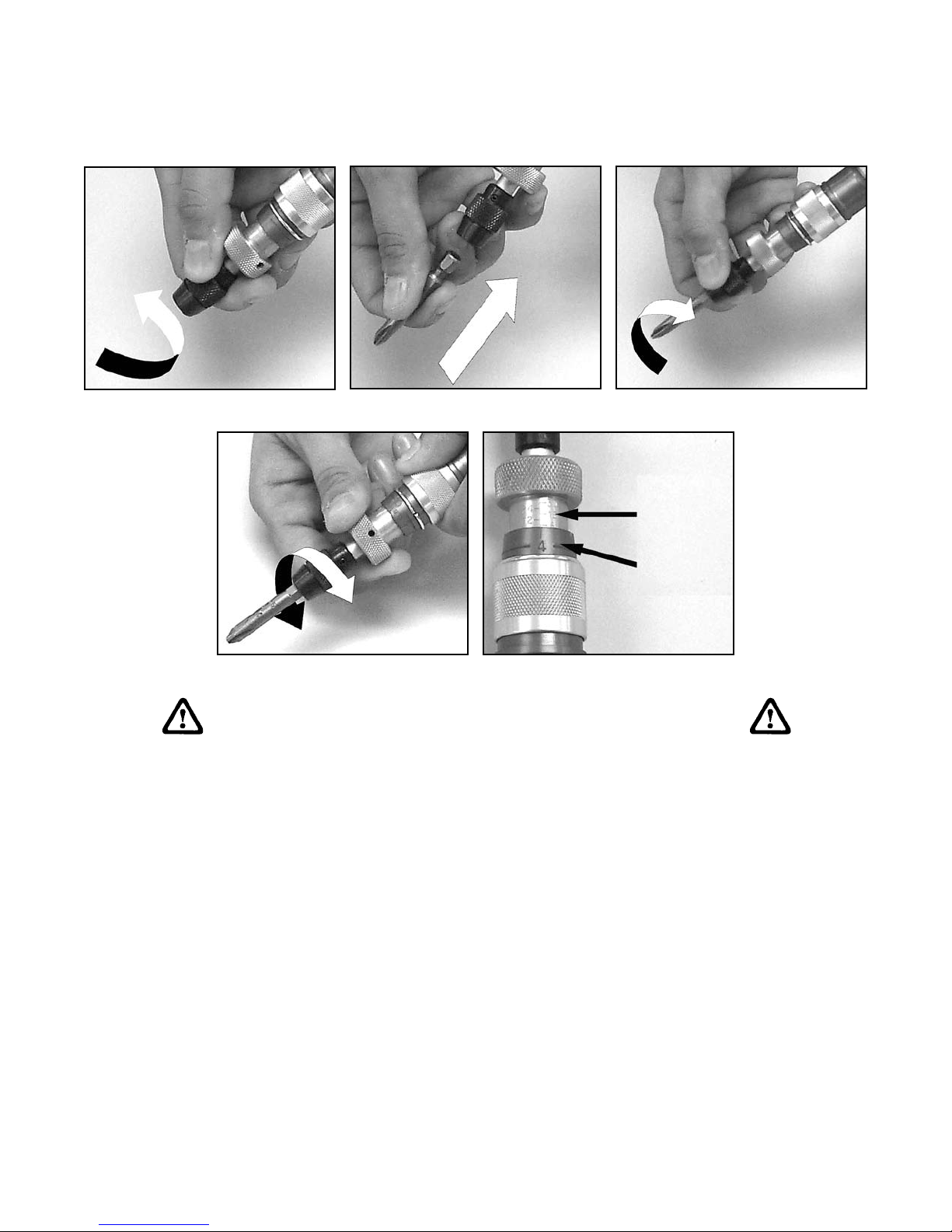

Inserting and Removing Bits

12 3

Setting the Torque

12

Total Torque =

Major Scale

+

Minor Scale