66

Precautions for use:Precautions for use:

In the event of oil leakage from the cylinder body, check and replace the seal rings (12,14,In the event of oil leakage from the cylinder body, check and replace the seal rings (12,14,

16). Also check the guide sleeve and 16). Also check the guide sleeve and cylinder body for damage.cylinder body for damage.

Periodically check the bearings (10,19) and their seal rings (9,20), and replace promptly ifPeriodically check the bearings (10,19) and their seal rings (9,20), and replace promptly if

damaged. Also change grease on a regular basis.damaged. Also change grease on a regular basis.

Periodically check the bearings (26, 28), and their seal ring (25), and replace promptly ifPeriodically check the bearings (26, 28), and their seal ring (25), and replace promptly if

damaged. Also change grease on a regular basis;damaged. Also change grease on a regular basis;

Adjusting the Adjusting the preload of preload of the sthe steered wheel teered wheel hub hub bearingbearings: s: remove the remove the counterweigcounterweight ht and itsand its

cover panel, then jack up the rear of the frame with an automotive jack so that the wheel iscover panel, then jack up the rear of the frame with an automotive jack so that the wheel is

off the ground. Tighten nut (3) until the steered wheel hub cannot be moved by hand, thenoff the ground. Tighten nut (3) until the steered wheel hub cannot be moved by hand, then

rotate it 1/6 to rotate it 1/6 to 1/4 turn in 1/4 turn in the opposite direction.the opposite direction.

Adjusting the preload of the support bearings (10,19): Adjusting the preload of the support bearings (10,19): Remove counterweigRemove counterweight and its coverht and its cover

panel, then jack up the rear of the frame. Tighten nut (8) until the steering spindle cannot bepanel, then jack up the rear of the frame. Tighten nut (8) until the steering spindle cannot be

moved by hand, then rotate nut (8) 1/6 moved by hand, then rotate nut (8) 1/6 to 1/4 turn in to 1/4 turn in the opposite direction.the opposite direction.

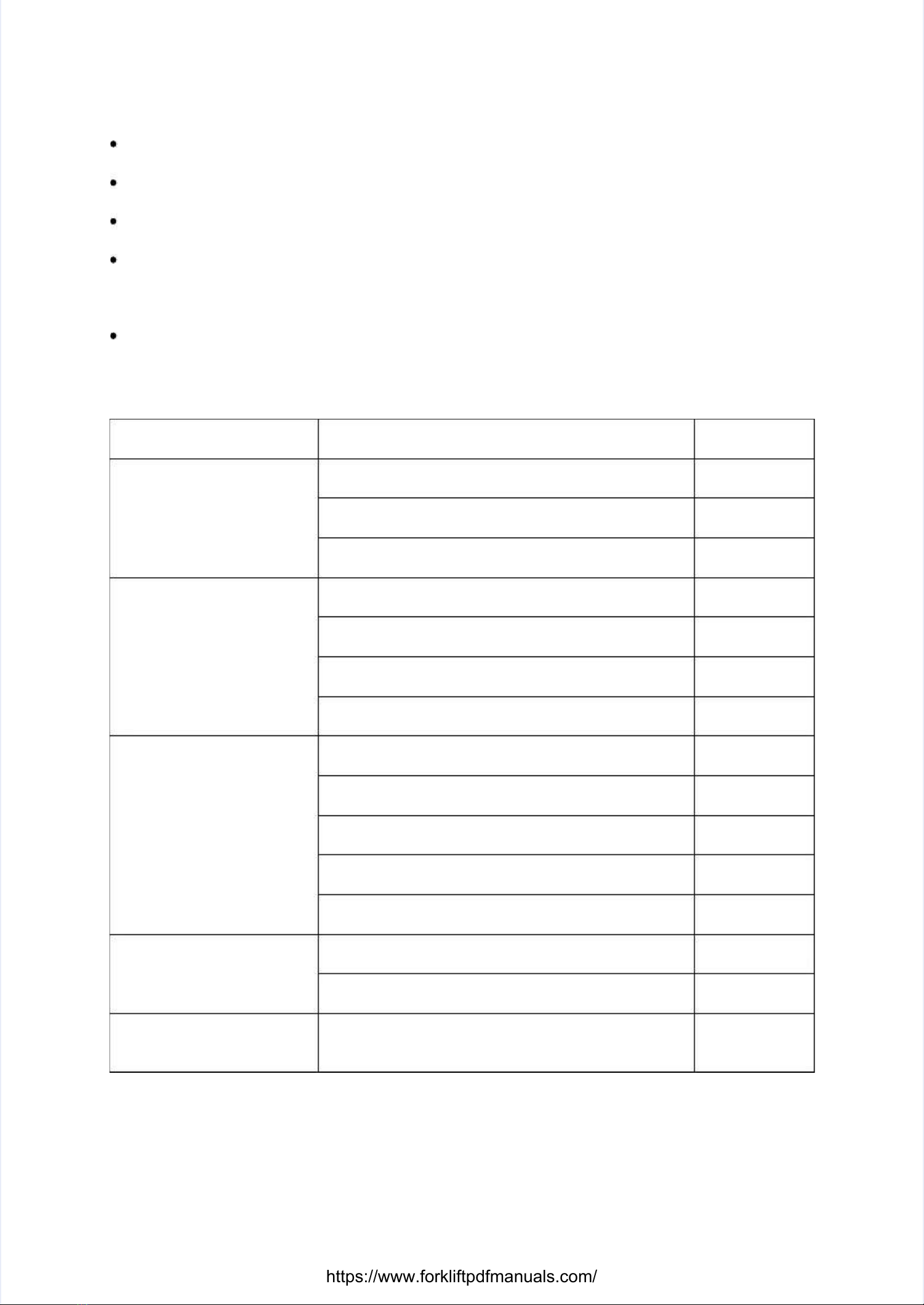

Problem Problem Cause Cause Analysis Analysis RemedyRemedy

Steering wheel will not turnSteering wheel will not turn

Pump Pump damaged damaged or or faulty faulty ReplaceReplace

Clogged or damaged priority valveClogged or damaged priority valve Flush orFlush or

replacereplace

Hose or connector damaged or pipe blockedHose or connector damaged or pipe blocked Replace orReplace or

flushflush

Steering is hardSteering is hard

Diverter valve pressure too lowDiverter valve pressure too low AdjustAdjust

pressurepressure

Air in the oil line Air in the oil line Bleed off airBleed off air

Steering gear fails to centre, positioning springSteering gear fails to centre, positioning spring

broken or weakbroken or weak

ReplaceReplace

springspring

Excessive leakage inside steering cylinderExcessive leakage inside steering cylinder Check pistonCheck piston

sealseal

Abnormal noiseAbnormal noise

Low Low oil oil tank tank level level Add Add oiloil

Damaged Damaged steering steering gear gear shaft shaft rack rack ReplaceReplace

Damaged Damaged wheel wheel bearing bearing or or support support bearing bearing ReplaceReplace

Inadequate Inadequate lubrication lubrication Add Add greasegrease

Clogged suction pipe or oil filterClogged suction pipe or oil filter Flush orFlush or

replacereplace

Oil leakOil leak

Defective steering cylinder seal ring or damagedDefective steering cylinder seal ring or damaged

pipe or connectorpipe or connector ReplaceReplace

Damaged wheel hub bearing or support bearing orDamaged wheel hub bearing or support bearing or

seal ringseal ring

Replace sealReplace seal

ringring

Steering angles of left andSteering angles of left and

right drive wheels (frontright drive wheels (front

wheels) do not matchwheels) do not match

Controller Controller parameters parameters incorrect incorrect AdjustAdjust