Page 3UTS SALES & REPAIRS LTD

Description, Safety Notes & Fittings

Description

The UTS 500 NARROW tower is manufactured to ISO 9001

• Instructions for erection and use to be followed carefully.

• A risk assessment should always be carried out before erecting your MAT (Mobile Access Tower).

• You will nd a standard risk assessment form at the back of this instruction manual.

• The UTS 500 NARROW has a maximum working platform height of 6.3 meters indoors or outdoors.

• The maximum permissible load on the UTS 500 NARROW tower is 550kgs and evenly distributed on each

platform is 275kgs. This must not be exceeded over the working height platform, not including rest platforms.

• Maximum of 1 working platform per tower.

• Maximum of 1 person per working platform.

• Damaged or incorrect components shall not be used.

Safety Notes

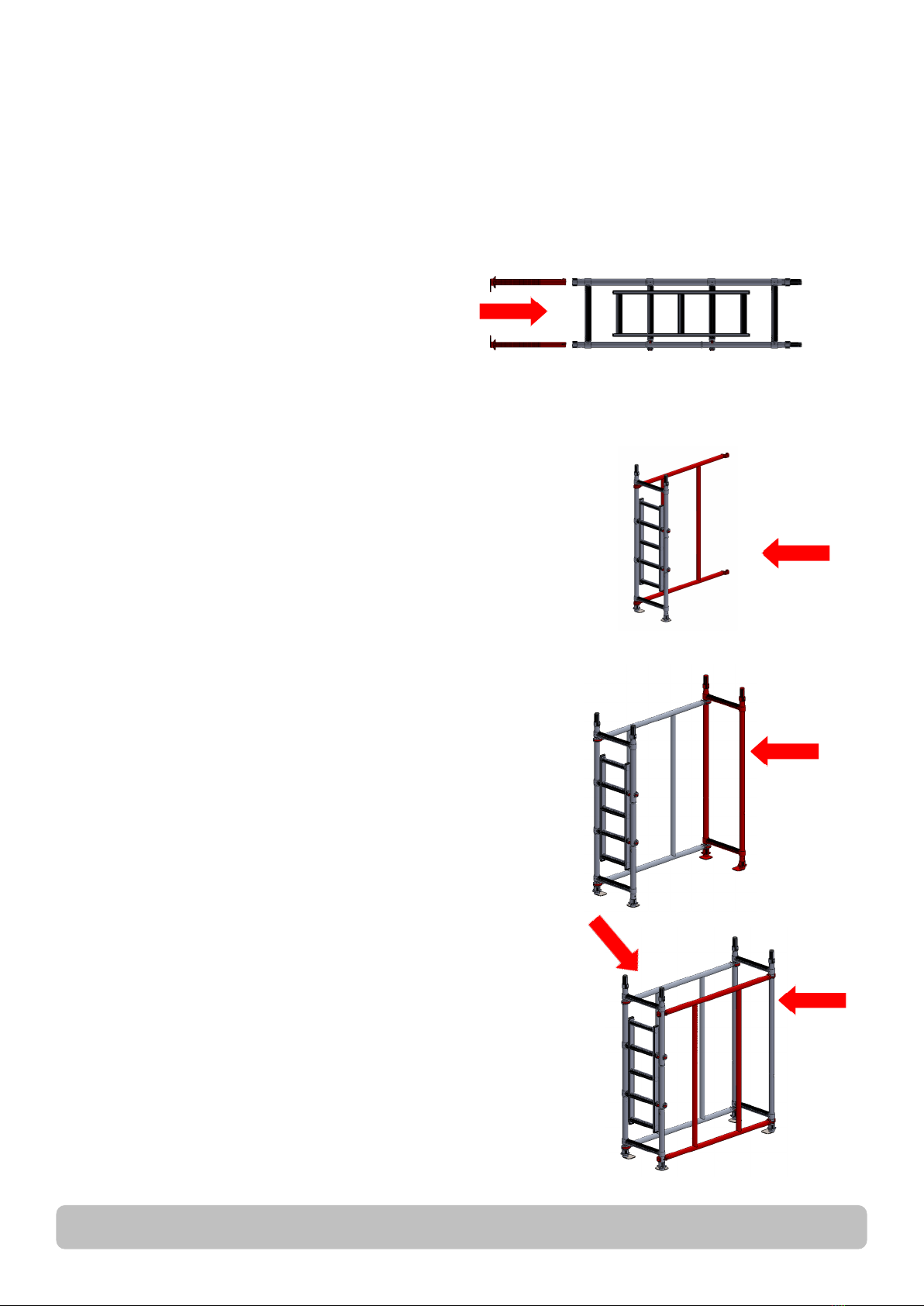

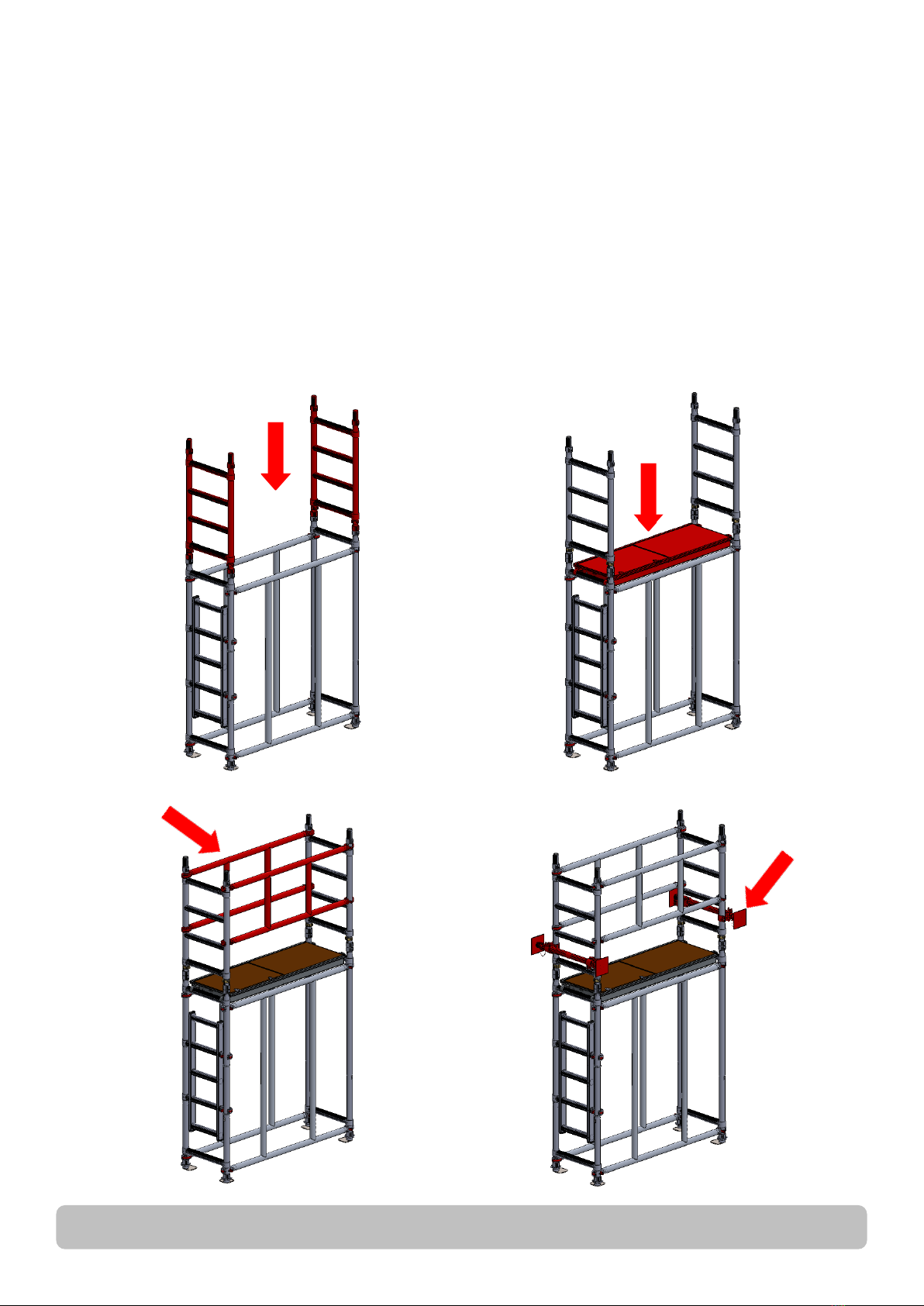

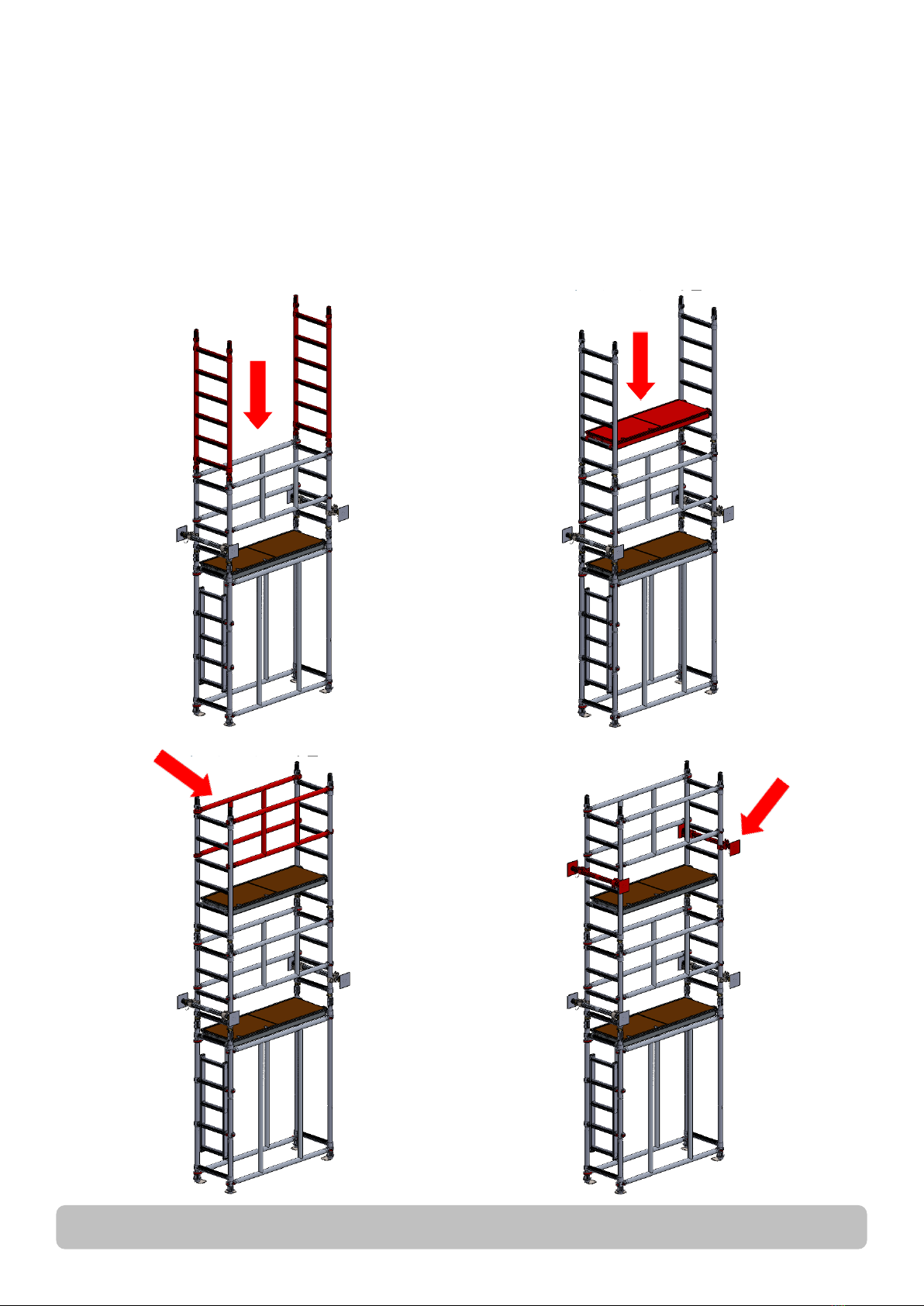

ERECTION & DISMANTLING - THE 3T(through the trap) METHOD

Towers should be erected following a safe method of work, there are two approved methods recommended by

‘Prefabricated Access Suppliers & Manufacturers Association’ (PASMA) in co-operation with the Health and Safety

Executive (HSE) & the “working at height regulations 2005”

The method used for erecting and dismantling the UTS 500 NARROW tower is the 3T METHOD (through the trap).

This method ensures the operators erecting the tower position themselves in the trapdoor of the platform to add or

remove horizontal guardrail braces for the level above the platform.

NEVER STAND ON AN UNGUARDED PLATFORM.

Before assembly or erection of this Mobile Access Tower (MAT) please ensure that:

• A risk assessment has been done and all safety equipment is on site.

• The ground conditions will take the working loads of MAT as specied.

• Always check that the MAT is vertical, (Level, slope, uneven ground etc.) if levelling is required make sure you

adjust legs , in line with instructions (use spirit level).

• Beware of (overhead) obstructions – live wires, electrical apparatus or moving parts of machinery or other.

• Wind conditions are within limits as specied. (Refer to page 6)

• Do not use boxes, ladders, or other devices on the platform to gain additional height.

• If in doubt DO NOT ERECT.

• Check that all components are on site and that they are in good working order before use (refer to the

components and quantities shown at each stage). Auxiliary equipment and safety equipment. (ropes, etc)

• All platforms MUST have horizontal guardrails tted.

• The tower should always be accessed from the inside using the rungs of the end frames.

• Never climb up the outside.

• Do not use the guardrail braces as a rung or step.

• It is recommended that 2 persons erect this tower.

• The assembled tower should not be used as a means to enter or exit other structures, e.g. as a stair tower.

• Beware of horizontal forces (e.g., when using power tools on an adjacent structure), which could generate

instability or overturning of the tower.

• Maximum distance between platforms is 2.25m, maximum distance to the rst platform is 3.4m.

• Maximum horizontal force 20kgs.

• Mobile access and working towers are not designed to be sheeted

• The tower height used should be appropriate for the working height, e.g. within 2 meters above the platform