Dynamics

UVD32OE

Installation

and

Maintenance

Manual

READ

AND

UNDERSTAND

ALL

INSTRUCTIONS BEFORE

INSTALLING

OR

USING

THIS

PRODUCT

PERFORMANCE

CONSIDERATIONS

The

performance

of

the

UVD320E

UV

disinfection

chamber

has

been

third

party

validated

using

accepted

bio-assay techniques.

The

UVD320E

is

equipped

with

both

visible

and

audio

lamp

failure

alarms.

For

your

safety,

it

is

necessary

that

you

determine

that

the

audio

alarm

can

be

heard

where

you use

the

water

treated

by

the

unit.

It

is

possible

to

operate the

unit with the

lamp

disconnected

which

will

allow

you

to

validate

the

adequacy of

the

audio

alarm

function

in

your

installation.

In

order

to

optimize

disinfection

performance,

you

must

only

use

the

unit with

water

that

meets the

minimum

standard

and

replace

the

UV

lamp

at

recommended

intervals. Failure

to

follow

these

guidelines

will

result

in

reduced

disinfection

performance.

UV

RADIATION

HAZARD

•

NEVER

OPERATE

UV

LAMP OUTSIDE

OF

THE

UV

•

DISINFECTION

CHAMBER

—

EXPOSURE

TO

UV

LIGHT

CAN

RESULT

IN

EXTREME

BURNING

OF

SKIN

AND

EYES

Safety

instructions

—

Please

read

carefully

/I\

Danger:

Do

not

plug

the

unit

in

if

any

of

the

external

surfaces or

electrical

parts

are

wet.

Condensation

on

the

disinfection

chamber

is

normal.

Danger:

To

avoid

possible electnc

shock,

special care should

be

taken

since

water

may

be

present

near

electrical equipment. Unless

referred

to

in

these

instructions,

do

not

attempt repairs

yourself.

Contact

the

manufacturer

for service

advice.

Danger:

Do

not

operate this

system

if

it

has

a

damaged

electrical

cord

or

plug,

is

malfunctioning,

or

has

been

dropped

or

damaged

in

any

way.

Caution:

Do

not

use

this

unit

for

anything

other

than

its intended

potable

water

application.

The

use

of attachments

not

recommended,

approved

or

sold

by

the

manufacturer/distributor

may

result

in

an

unsafe condition.

____

INSTALLATION

CAUTIONS

Connect your

UV

unit

to

a

grounded

(3

pronged)

receptacle

(120V,

60HZ)

(a

GFI

is

highly

recommended)

and

ensure

that

the

lamp

connector

ground

wire

is

connected

to

the

ground

stud

on

the

top

of

the

reactor

vessel.

Note:

Power

source

for

applications outside

of

North

America

must

match

requirements

of

the

unit

(eg.

240V,

50Hz).

OUV

Dynamics

disinfection devices

are

designed

to

be

installed

on

the

cold

water

line

only.

OThe

unit

must

be

installed

vertically

with the lamp

connector

pointing

upwards

—

the

water

source

should only

be

connected

to

the

inlet

port

on

the

bottom of

the

unit.

CAUTION:

reversing

the

flow

direction

by

connecting

the

water

source

to

the

side mounted

output

port

could result

in

reduced

disinfection performance.

Olnstall

your

UV

Dynamics

disinfection

system indoors

in a

protected

area where the

temperature

does

not

fall

below

4°C.

(40°F) and

the

humidity

level

is

low

(to

prevent

condensation

on

the

chamber). This

unit

functions

ideally

in

a

temperature

range

from

9°C

-

29°C.

(49—

85F)

OUse

teflon

tape

on

all

pipe connections.

DO

NOT

USE

ANY

OTHER SEALANT.

O

If

the

installation

location

is

subject

to

frequent

power

outages,

surges,

brown

out

conditions

or

electrical

storm

activity,

a

surge

protection

device

should

be

installed

on

the

AC

supply

to

prevent

damage

to

the power source.

O

Do

not

connect UVDynamics disinfection

systems

directly

to

PEX

tubing

or

other

plastic

piping.

Plastic

material

will

suffer

structural

degradation,

and

possible

service

failures, when subjected

to long-

term

UV

light

exposure.

PEX

tubing

and

plastic

piping

can

be

connected

directly

to

the

inlet

port

if

it

is

located

on

the

bottom

of

the

chamber. All

side ports

will

require

the

use

of

a

metallic

light

dam

(16”/4Ocm section

of

metallic

tubing, street elbow

or

stainless

steel

flex

connector

suitably

bent

to

prevent

direct

UV

radiation)

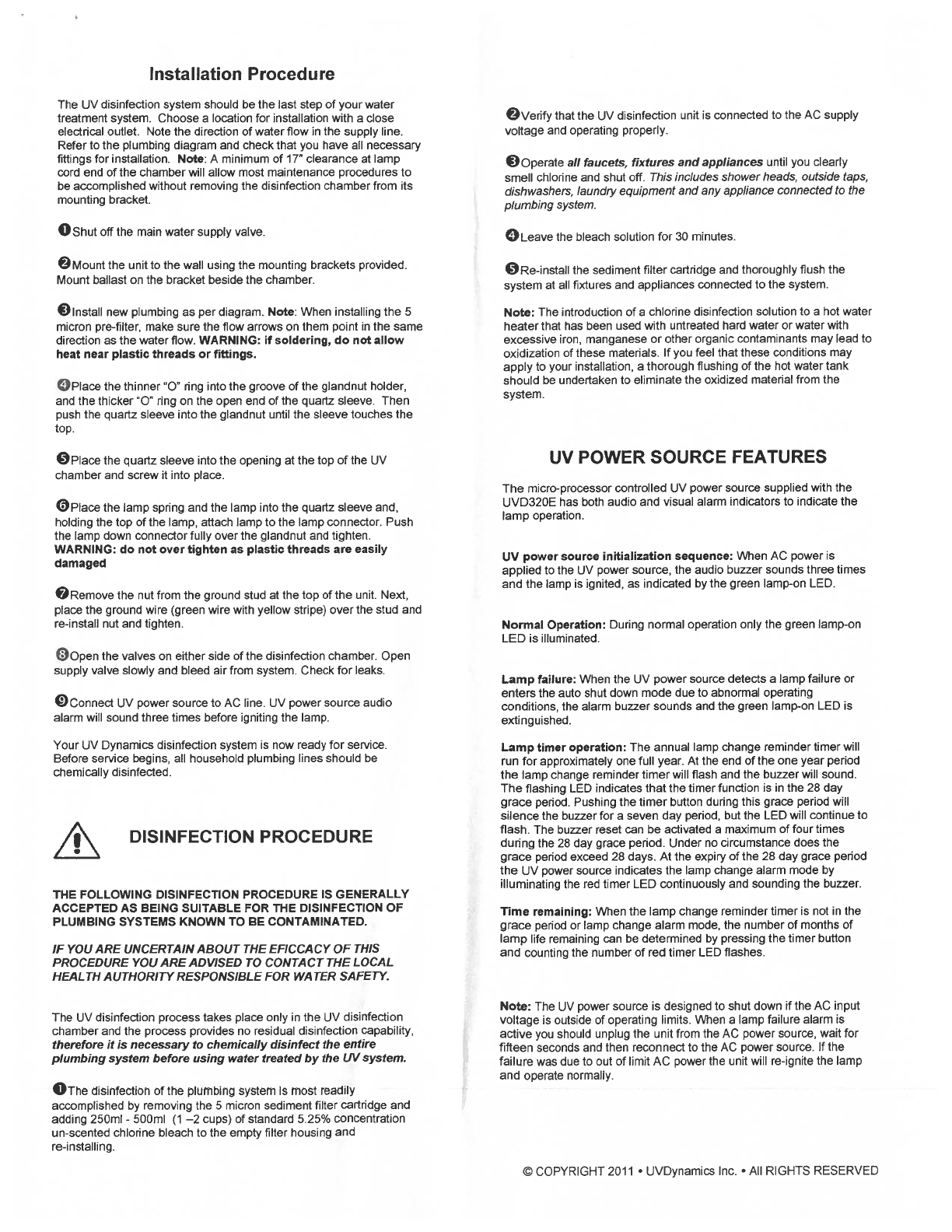

SUGGESTED

INSTALLATION

LAMP

CONNECTOR

GLANONUT

MOUNTING

BRACKET

UV

POWER

SOURCE

MOUNTING SURFACE

LW

POWER

SOURCE

MOUNTING

DETAIL

Caution:

Before

any

cleaning

or

maintenance, always

unplug

the

unit.

Caution:

Protect

your

unit

from

freezing.

Drain

all

water

from

the unit

if

freezing

temperatures

exist.

Caution:

To

prevent damage

to

the

power

source

the

use

of

a

surge

protector

is

recommended

in

areas

with

frequent

power

outages.

WATER

QUALITY

Your

UV

disinfection

system requires

clean

water

for

optimum

performance.

You

should only operate

your

unit

if

the

source

water

meets

the

following

standards.

ISi~~_ab

~‘

b1

VALVE

‘~

VALVE

IJN1ON

I

0•

FILTER

1

~3I4’MNPT

UV

REACTOR

CHAMBER

MOUNTING DETAIL

MOUNTING

SURFACE

PLASTIC

BRACKET

WORMGEAR CLAMP

UV

CHAMBER

I

DIRECTION

OF

FLOW

Turbidity

<1

NTU

Suspended

Solids

<lOmgIL

Colour

None

Total

Iron

<0.3

mgIL

Manganese

<0.06

mg/L

Hardness

<7

gpg

UV

Dynamics

Inc. www.

uvdynarnics.

corn

315

Neptune Crescent.

London. Ontario,

N6M

1A9

phone

800.667.4629

fax

519.452.1701

©

COPYRIGHT

2011

UVDynamics

Inc.

•

All

RIGHTS

RESERVED