Installation

Procedure

The

UV

disinfection

system should

be

the last

step

of

your

water

treatment

system.

Choose

a

location

for

installation

with

a

close

electrical

outlet.

Note

the

direction

of

water flow

in

the

supply

line.

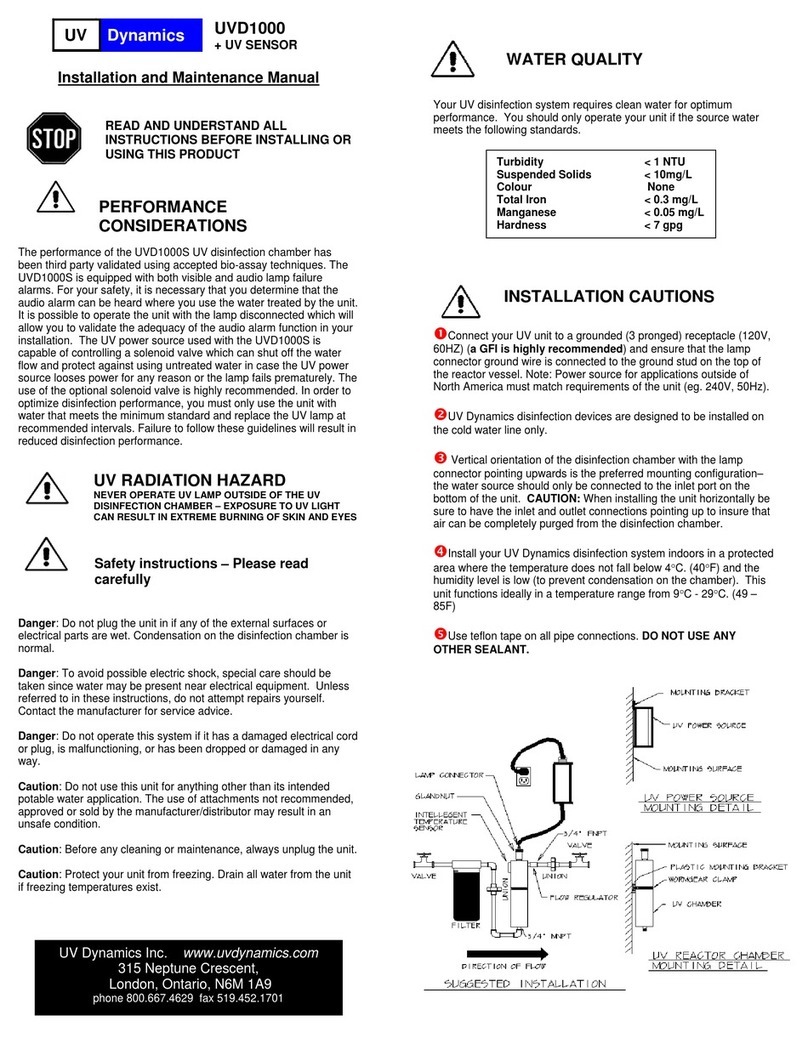

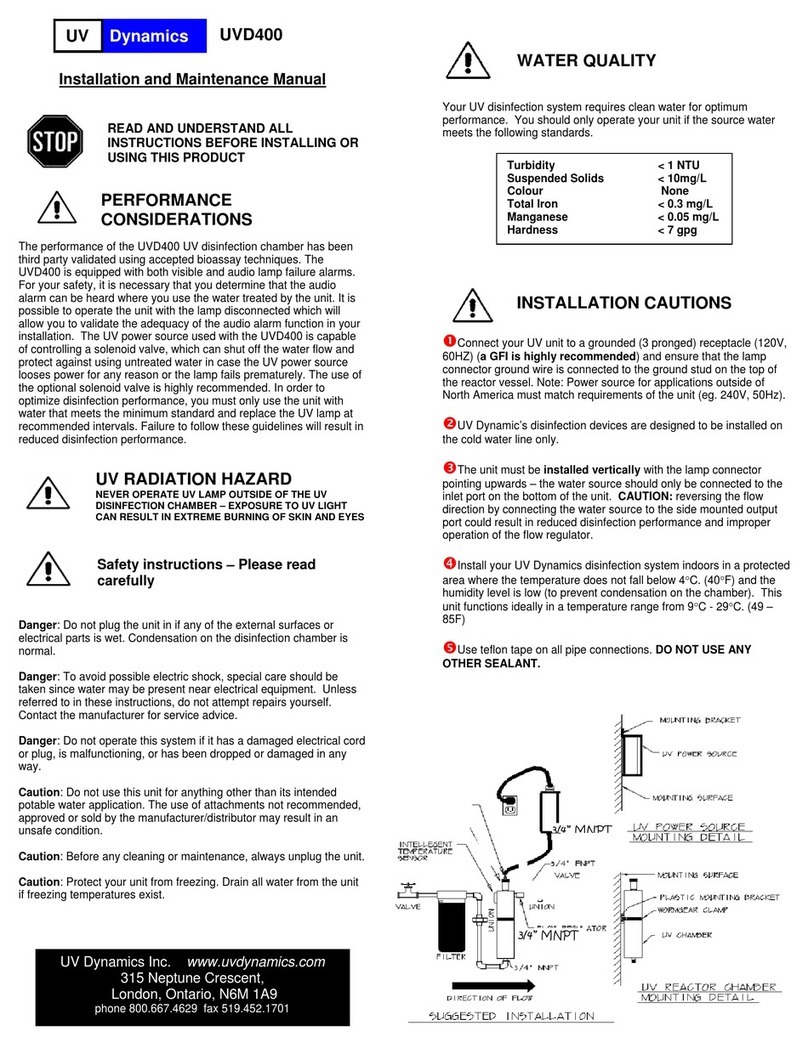

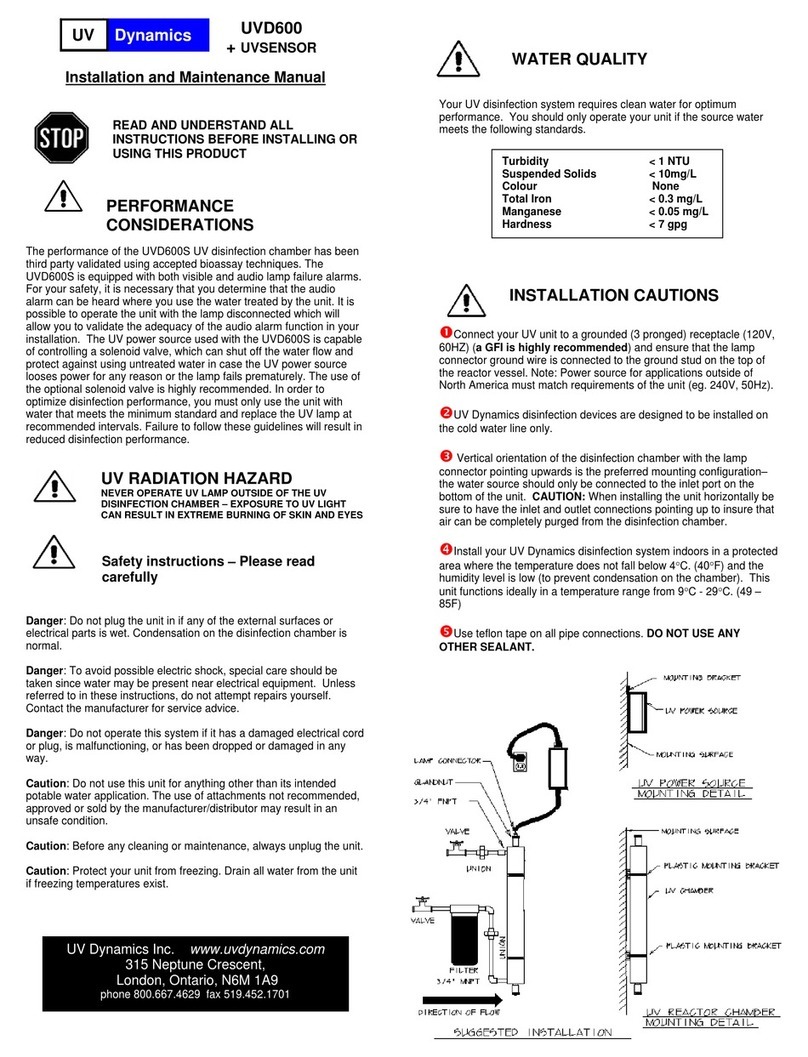

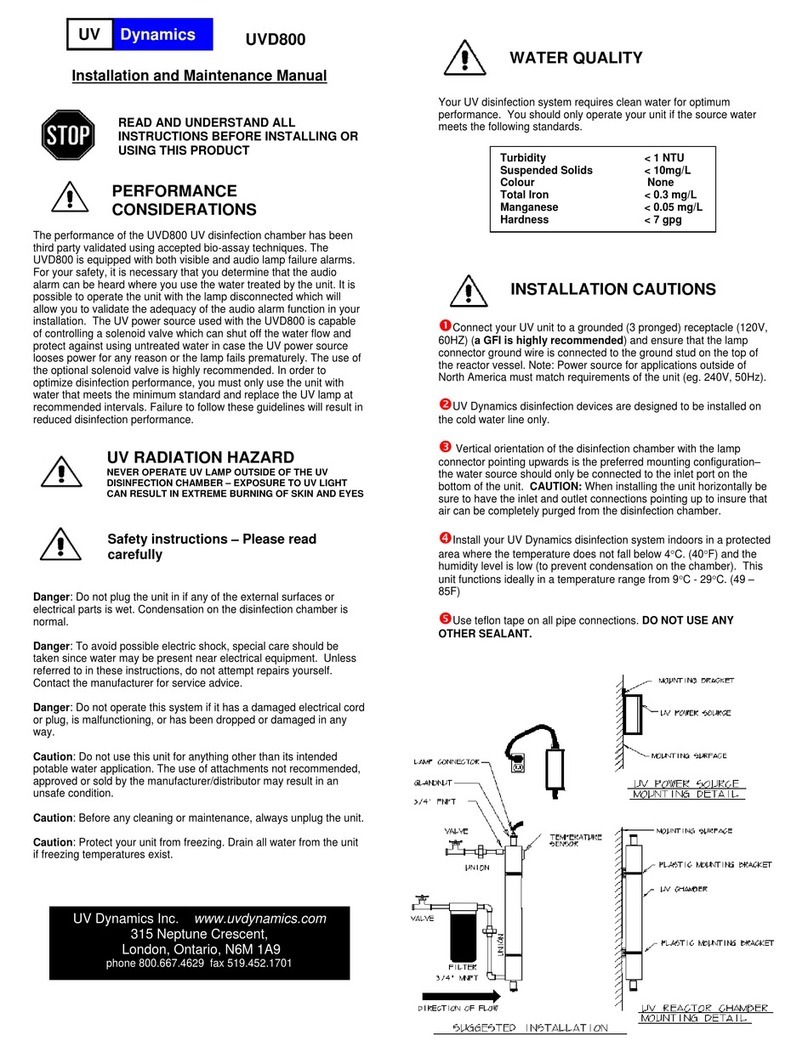

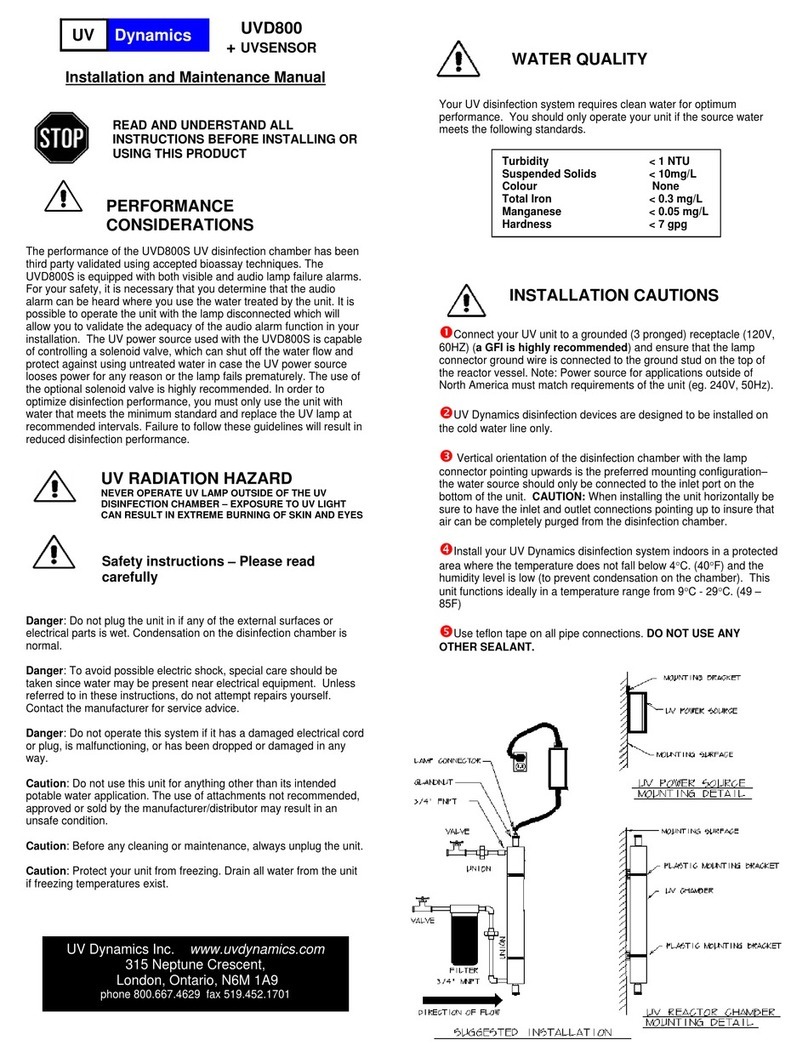

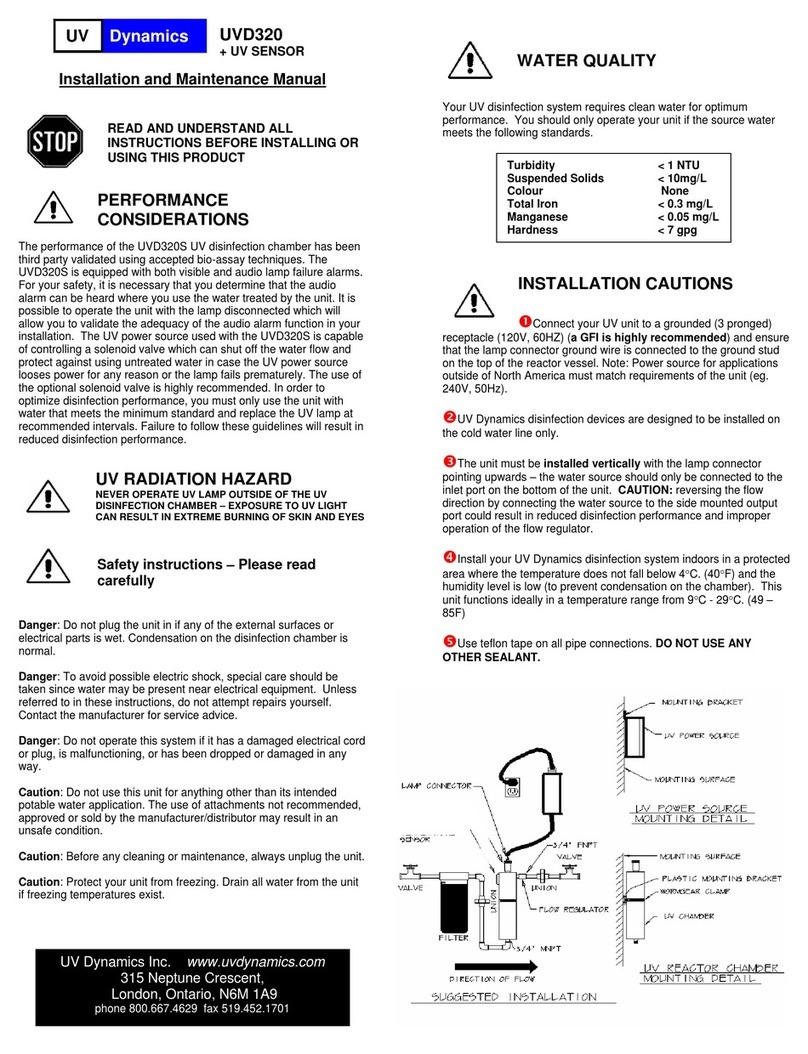

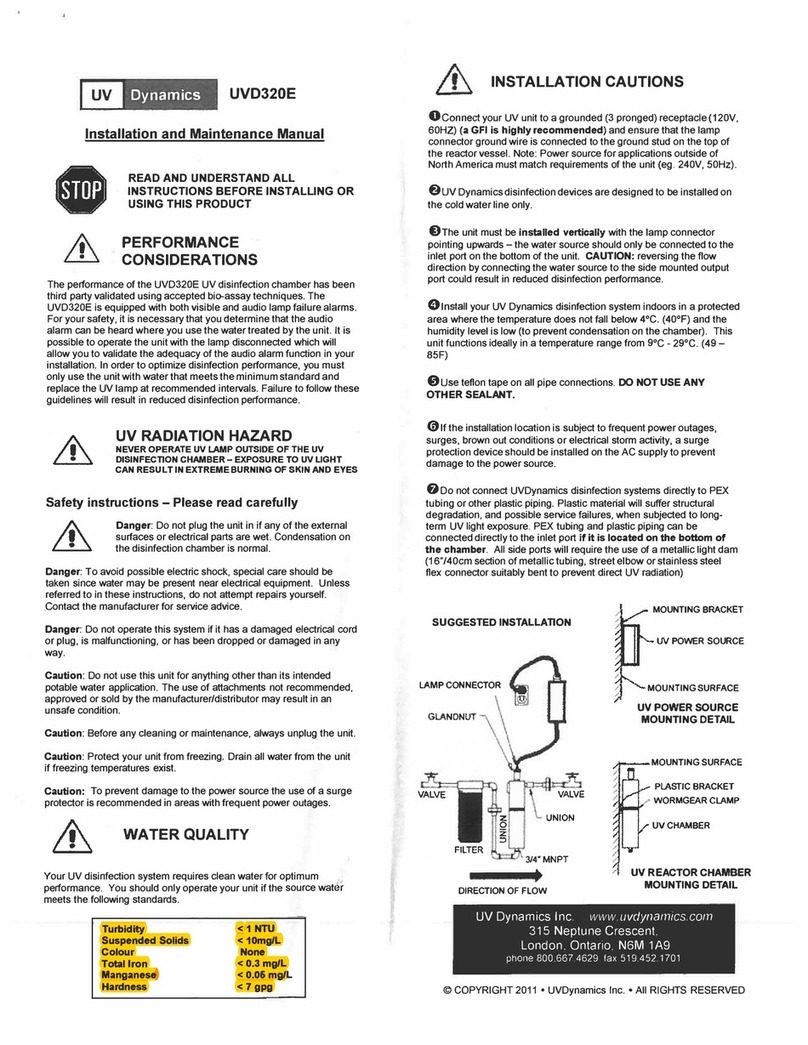

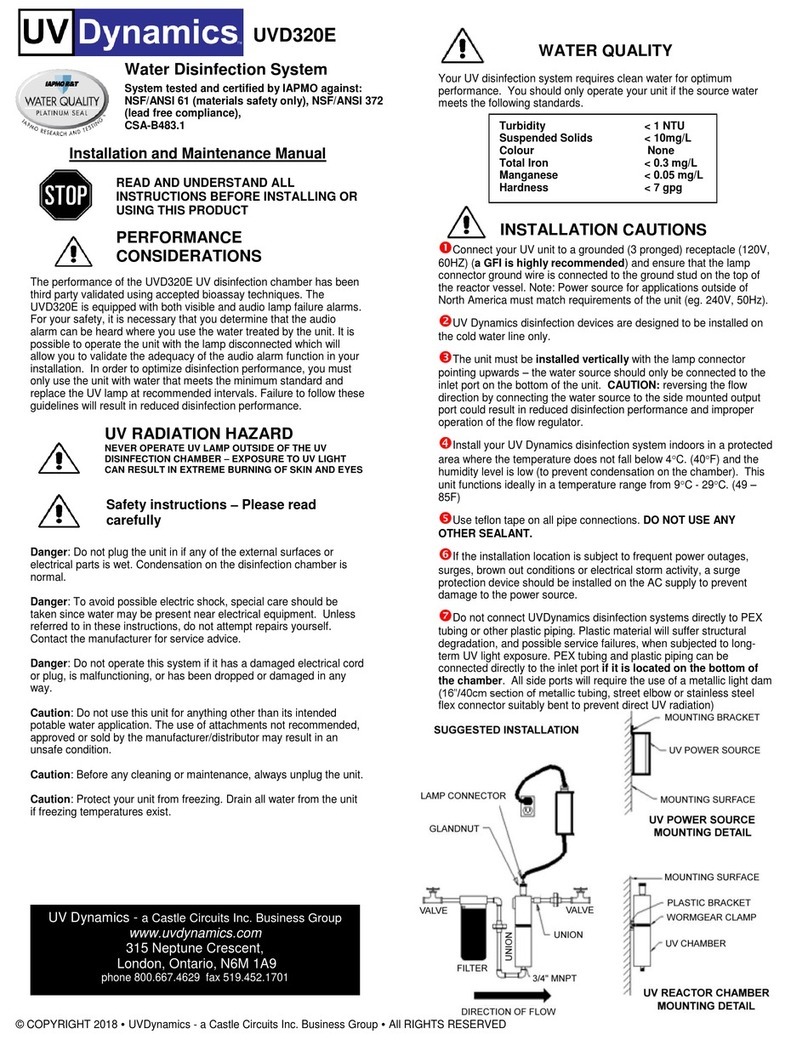

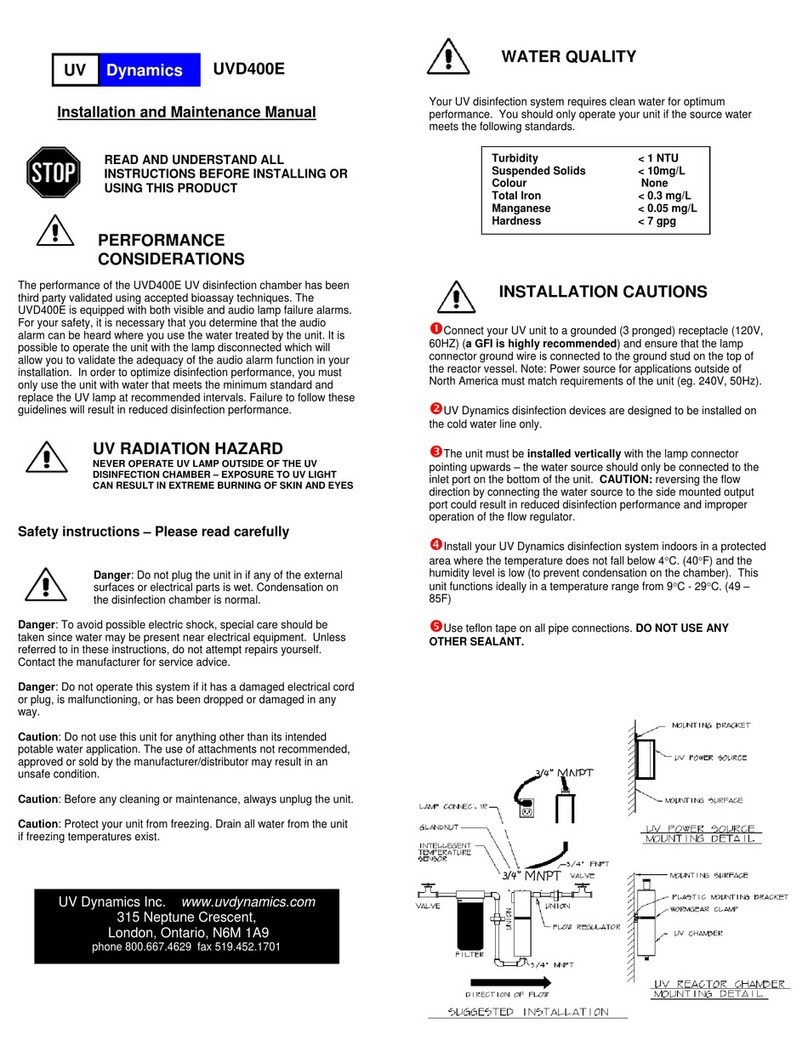

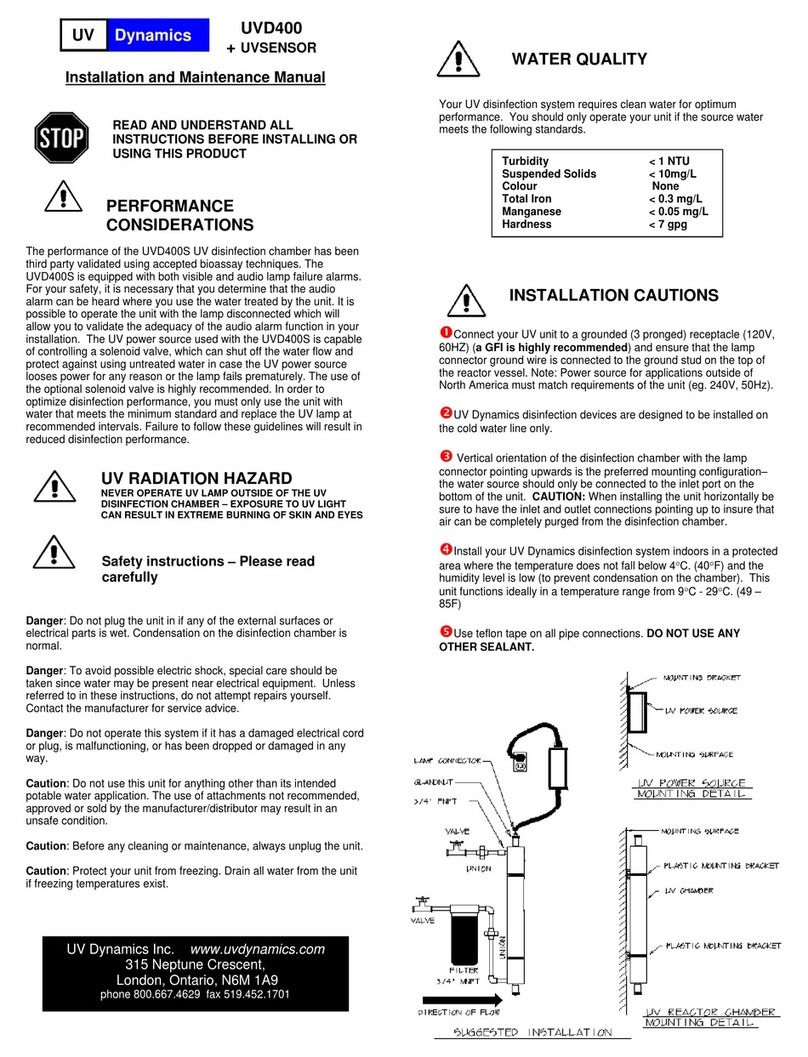

Refer

to

the

plumbing

diagram

and

check

that

you have

all

necessary

fittings

for

installation.

Note:

A

minimum

of

15”

clearance

at

lamp

cord

end

of

the

chamber

will

allow

most

maintenance procedures

to

be

accomplished without

removing

the

disinfection

chamber

from

its

mounting

bracket.

0

Shut

off

the

main

water

supply

valve.

0

Mount

the

unit

to

the

wall using

the

mounting

bracket

provided.

Mount

ballast

on

the

bracket

beside

the

chamber.

OlnstalI

new

plumbing

as

per diagram.

Note:

When

installing

the

5-

micron

pre-filter, make

sure

the

flow

arrows

on

them point

in

the

same

direction

as

the

water

flow.

WARNING:

if

soldering,

do

not allow

heat

near

plastic

threads

or

fittings.

OPlace

the

thinner

“0”

ring

into the

groove

of

the

gland

nut

holder,

and

the

thicker

“0”

ring on the

open

end

of

the

quartz

sleeve.

Then

push

the

quartz sleeve

into

the

gland

nut

until

the

sleeve

touches

the

top.

OPlace

the

quartz

sleeve

into

the

opening

at

the

top

of

the

UV

chamber

and

screw

it

into place.

OPlace

the

lamp

spring

and

the

lamp

into

the

quartz

sleeve

and,

holding

the

top

of

the

lamp,

attach

lamp

to

the

lamp

connector.

Push

the

lamp

connector

down

snugly

into

the

gland

nut

and

tighten

the

retainer

screw.

WARNING:

do

not

over tighten

as

plastic

threads

are

easily

damaged

ORemove

the nut from

the

ground

stud at

the

top

of

the unit.

Next

place

the

ground

wire

(green

wire

with

yellow

stnpe)

over

the

stud

and

re-install

nut

and tighten.

OOpen

the

valves

on

either

side

of

the

disinfection

chamber.

Check

for

leaks.

Open supply

valve

slowly and bleed

air

from

system.

OConnect

UV

power

source

to

AC

line.

UV

power

source

audio

alarm

will

sound

three

times

before

igniting

the

lamp.

‘~‘our

UV

Dynamics disinfection

system

is

now

ready

for

service.

Before

service

begins,

all

household

plumbing lines

should

be

chemically

disinfected.

j4’\

DISINFECTION

PROCEDURE

FHE

FOLLOWING

DISINFECTION PROCEDURE

IS

GENERALLY

ACCEPTED

AS

BEING

SUITABLE

FOR

THE

DISINFECTION

OF

FLUMBING

SYSTEMS

KNOWN

TO

BE

CONTAMINATED.

IF

YOU

ARE

UNCERTAIN

ABOUT

THE

EFFICACY OF

THIS

PROCEDURE

YOUAREADVISED

TO

CONTACT

THE

LOCAL

hEALTH

AUTHORITY

RESPONSIBLE

FOR

WATER

SAFETY.

The

UV

disinfection

process takes place only

in

the

UV

disinfection

chamber

and

the

process provides

no

residual

disinfection

capability,

therefore

it

is

necessary to chemically

disinfect

the

entire

plumbing

system

before

using

water treated

by

the

UV

system.

eThe

disinfection

of

the

plumbing

system

is

most

readily

accomplished

by

removing the

5

micron

sediment

filter

cartridge

and

adding

250m1

-

500m1

(1

—2

cups)

of standard 5.25%

concentration

un-scented

chlorine

bleach

to

the

empty

filter

housing

and

r~-installing.

OVenfy

that

the

UV

disinfection

unit

is

connected

to

the

AC

supply

voltage

and

operating

properly.

O

Operate

all

faucets,

fixtures

and

appliances

until you

clearly

smell

chlorine

and

shut

off.

This

includes showerheads, outside

taps,

dishwashers,

laundry equipment

and

any

appliance

connected

to

the

plumbing

system.

OLeave

the

bleach

solution

for

30

minutes.

ORe-install

the

sediment

filter

cartridge

and

thoroughly

flush

the

system at

all

fixtures

and

appliances

connected

to

the system.

Note:

The

introduction

of

a

chlorine

disinfection solution

to

a

hot

water

heater that

has

been

used

with

untreated

hard

water or

water

with

excessive

iron,

manganese

or

other

organic

contaminants

may

lead

to

oxidization

of

these

materials.

If

you

feel

that

these

conditions

may

apply

to

your

installation,

a

thorough

flushing of

the

hot

water

tank

should

be

undertaken

to

eliminate

the

oxidized material

from

the

system.

UV

POWER SOURCE

FEATURES

The

microprocessor

controlled

UV

power

source

supplied

with

the

UVD245 has both

audio

and

visual

alarm

indicators

to

indicate

the

lamp

operation

and

an

integral annual

lamp

change

reminder

timer.

UV

power

source initialization

sequence:

When

AC

power

is

applied

to

the

UV

power

source

the

lamp

is

ignited as

indicated

by

the

green

lamp-on

LED,

after

which

the

power

source

conducts

a

self

test

of

the

annual

lamp

change

reminder

timer

LED

and

alarm

buzzer

consisting

of

three

buzzer

beeps

and three

red

timer

LED

flashes.

If

a

solenoid

is

connected

to

the

UV

power

source

it

will

activate

on

completion of

the

self-test

sequence.

Normal

Operation:

During

normal

operation only

the

green lamp-on

LED is

illuminated.

Lamp

failure:

When

the

UV

power

source

detects

a

lamp failure

or

enters

the

auto shut

down mode

due

to

abnormal

operating

conditions, the

alarm

buzzer sounds

and

the

green lamp-on

LED

is

extinguished.

If

connected,

the

solenoid valve

will

terminate

the

water

flow.

Lamp

timer

operation:

The

annual

lamp

change

reminder

timer

will

run

for

approximately

one

full

year.

At the

end of

the

one-year

period

the

lamp

change

reminder

timer

will

flash and

the

buzzer

will

sound.

The

flashing

LED

indicates

that

the

timer

function

is

in

the

28-day

grace

period.

Pushing

the

timer

button during

this

grace

period

will

silence

the

buzzer

for

a

seven-day

period,

but

the LED

will

continue

to

flash.

The

buzzer

reset

can

be

activated

a

maximum

of

four

times

during

the

28

day grace

period.

Under

no

circumstance

does

the

grace

period

exceed

28

days.

At

the

expiry

of

the

28-day

grace period

the

UV

power

source

indicates

the

lamp

change

alarm

mode

by

illuminating

the

red

timer

LED

continuously

and

sounding

the

buzzer.

Note:

The

UV

lamp

is

not shut

down

in

this alarm mode

and

the

solenoid valve

drive

is

not

disabled.

Time

remaining:

When

the

lamp change

reminder

timer

is

not

in

the

grace

period

or lamp

change

alarm

mode,

the

number

of

months

of

lamp life

remaining

can

be

determined

by

pressing

the

timer

button

and

counting

the

number

of

red

timer

LED

flashes.

Note:

The

UV

power

source

is

designed

to

shut

down

if

the

AC

input

voltage

is

outside

of

operating

limits.

When

a

lamp

failure

alarm

is

active

you

should

unplug

the

unit

from

the

AC

power

source, wait

for

fifteen

seconds

and then reconnect

to

the

AC

power

source,

If

the

failure

was

due

to

out

of

limit AC

power

the unit

will

re-ignite

the lamp

and

operate normally.

©

COPYRIGHT

2014.

UVDynamics

Inc.

•

All

RIGHTS

RESERVED