4

CWP-Series™

2. Introduction

Thank you for purchasing this UV-Guard Complete Water Purification system – the CWP-Series.

The CWP-Series purifies water to allow it to be safely consumed or used throughout your home

or commercial facility. This complete water treatment system combines filtration, adsorption and

UV disinfection – three processes proven to remove sediment, improve taste, clarity & odour, and

inactivate bacteria and pathogens in your water.

An eective rainwater treatment system – transforming your collected tank water to safe drinking

water. Can also be used for bore water and town water treatment.

The CWP-Series utilises components that need replacing to maintain optimum water treatment

performance.

1. Sediment Pleated Washable Filter

This filter acts as the first barrier and prevents dirt from passing to the next treatment stage.

When this filter becomes blocked, you will notice a drop in water pressure. It will need to be

removed and washed, or replaced when this occurs. The speed at which this filter requires

maintenance depends on the quality of water being treated. It is recommended that a first

flush divertor is installed to prolong the life of the filter. On average, these filters need to be

replaced twice per year.

2. Silver Impregnated Carbon Block Filter

Dissolved material that cause taste, colour and odour problems attach to the carbon

materials in this filter. As such, they do not have an infinite capacity. When you begin to

notice a colour, taste or odour change, replace this filter. Additionally, if there is a loss in

water pressure, this filter may also need to be replaced. On average, these filters need to be

replaced twice per year.

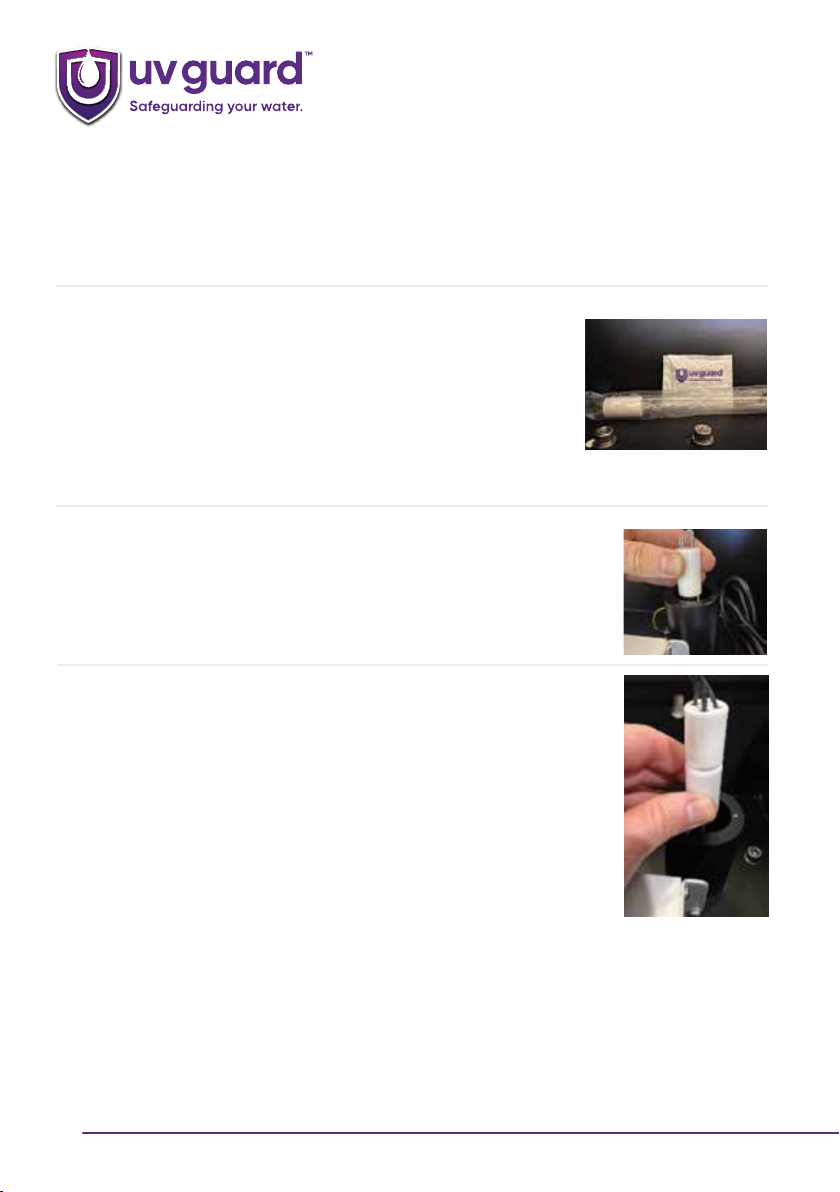

3. UV Lamp

The UV Lamp needs replacing after 365 days. The UV controller counts down from this number

of days and provides a warning when the UV Lamp end of life is nearing. After 365 days the

UV Lamp will still be on, but it will not be emitting the required UV radiation for recommended

disinfection. The UV Controller will also alarm should the UV Lamp fail.

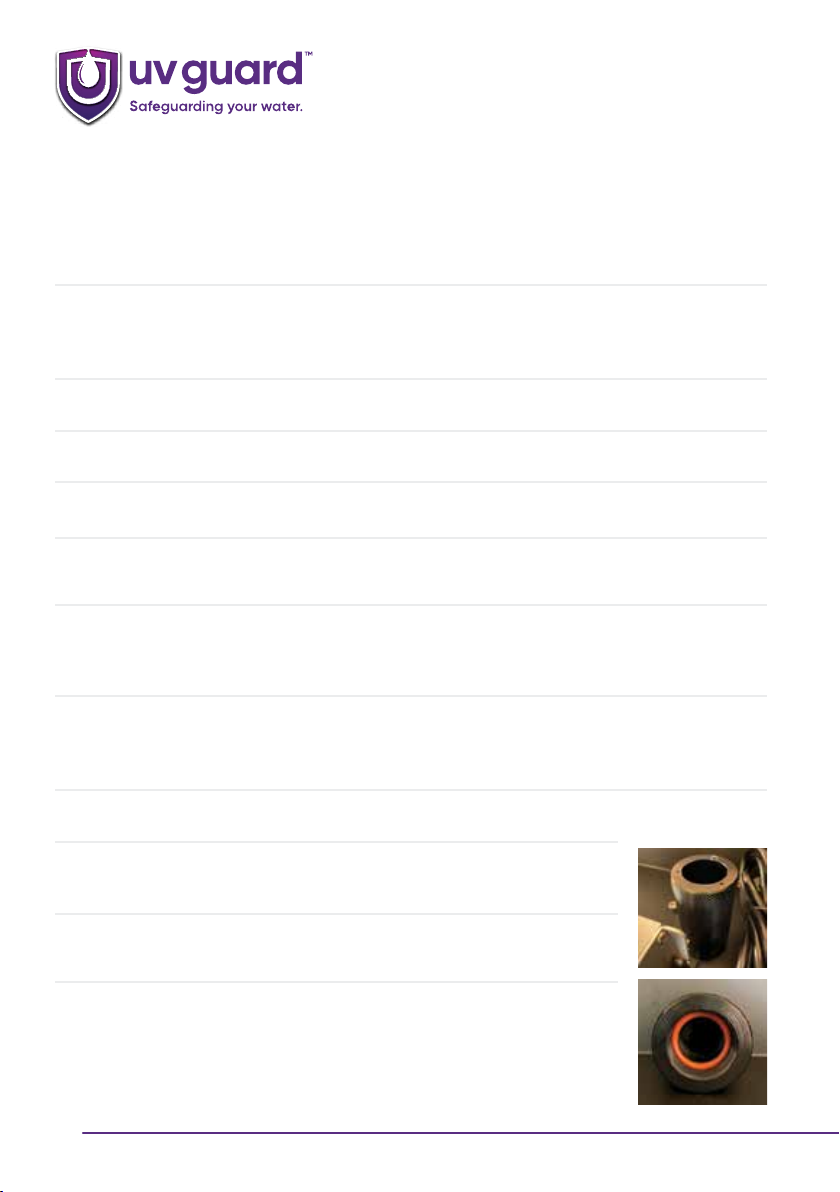

4. Quartz Sleeve and O-Ring

The Quartz Sleeve ensures that water does not reach the UV Lamp. Water flows around the

Quartz Sleeve and as such, it can become dirty over time. A dirty Quartz Sleeve results in the

UV Lamp being unable to disinfect the water. It is recommended that the Quartz Sleeve is

inspected regularly after installation. If it is dirty, it needs to be cleaned. If it is not dirty, the

inspection frequencies can be extended. For example, check 2 weeks after install, if not dirty,

check 4 weeks later, if not dirty, check 8 weeks later. Continue with this method until a Quartz

Cleaning frequency is established.

Quartz Sleeves need to be replaced every 2 years. However, if they are dirty to the point

where cleaning is not eective, they also need to be replaced. We recommend replacing the

O-Ring seal each time the Quartz Sleeve is removed to prevent O-Ring seal failure.