8Installation and maintenance instructions 0020213395_04

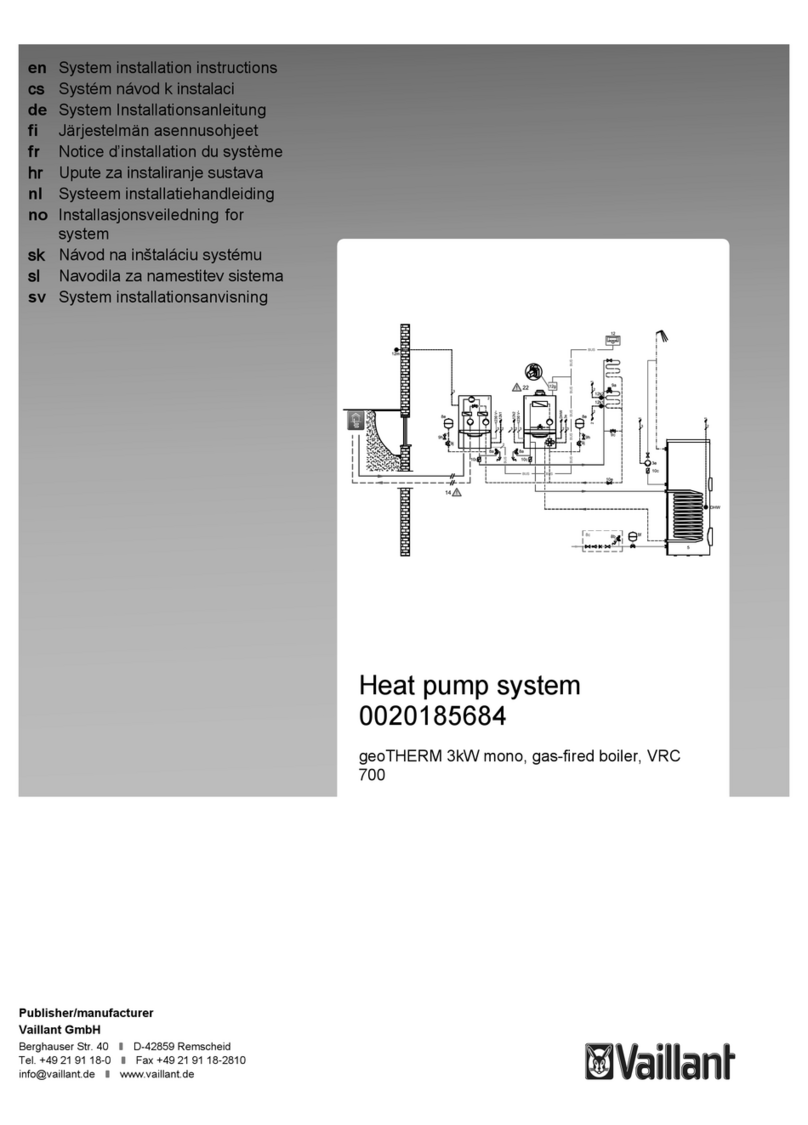

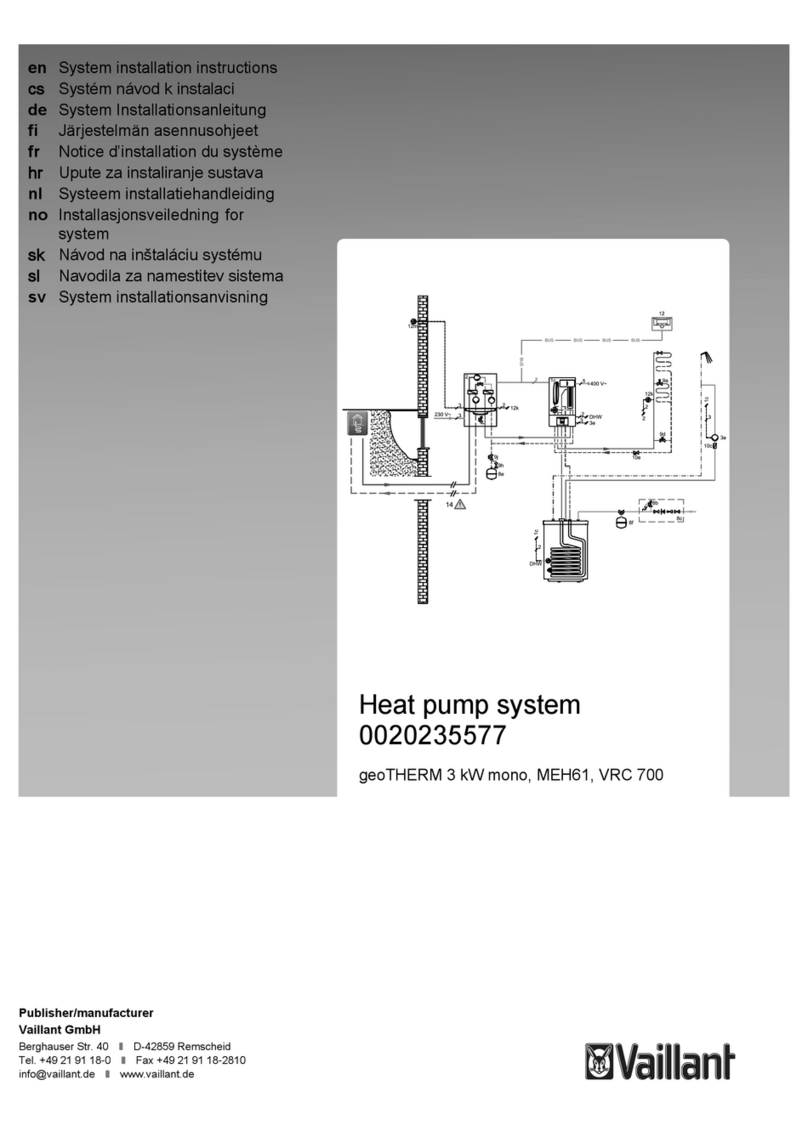

3 Heating circuit

4 Compressor

5 Refrigerant circuit

6 Brine circuit

7 Heat source

8 Brine pump

9 Evaporator

10 Electronic expansion

valve

11 Condenser

12 Heating/cylinder char-

ging diverter valve

13 Electric back-up heater

The heat pump system uses geothermal energy or ground

water as the heat source.

The heat pump consists of the following separate circuits

which are coupled with one another by means of heat ex-

changers. These circuits are:

–The brine circuit, which extracts the heat energy from

the ground or the ground water and transfers it to the

refrigerant circuit

–The refrigerant circuit, which is used to bring the heat

energy from the heat source to a usable, higher temper-

ature level and deliver it to the heating circuit

–The heating circuit, which is used to heat up the living

rooms

The refrigerant circuit is connected via the evaporator to the

heat source, from which it extracts heat energy. At the same

time, the physical state of the refrigerant changes; it evapor-

ates. The refrigerant circuit is connected via the condenser to

the heating installation, to which it releases the heat energy

again. In so doing, the refrigerant becomes liquid again; it

condenses.

As heat energy can only pass from a body at a higher tem-

perature to a body at a lower temperature, the refrigerant in

the evaporator must have a lower temperature than the heat

source. On the other hand, the temperature of the refrigerant

in the condenser must be higher than that of the heating wa-

ter in order to be able to release the heat energy to it.

These different temperatures are produced in the refrigerant

circuit by means of a compressor and an expansion valve,

which are located between the evaporator and condenser.

The refrigerant flows in vapour form from the evaporator into

the compressor, where it is compressed. This causes the

pressure and temperature of the refrigerant vapour to rise

sharply. After this process, it flows through the condenser,

where it releases its heat energy to the heating water by

condensation. It flows as a liquid into the expansion valve,

where it expands significantly and, in so doing, loses much

of its pressure and temperature. This temperature is now

lower than that of the brine that flows through the evaporator.

The refrigerant can thus absorb more heat energy in the

evaporator, turning into vapour in the process and flowing

to the compressor. The cycle starts again.

The evaporator and parts of the refrigerant circuit inside the

heat pump are cold-insulated, meaning that no condensate

can accumulate. Any small amounts of condensate which

may form evaporate as a result of the heat generated inside

the heat pump.

The heating water, which, when supplied, is colder in the

flow than the room temperature, absorbs heat energy

from the rooms and is pumped by the heating pump to the

condenser (which works as an evaporator when in cooling

mode). This heat energy is absorbed by the refrigerant and

heated to a higher temperature level using the compressor.

The heat energy is then delivered to the brine in the evapor-

ator (which works as a condenser when in cooling mode).

The cooled refrigerant is guided to the expansion valve to

enable heat energy to be absorbed from the condenser

again. The brine pump transports the hot brine into the earth,

where the heat energy is dissipated.

During the installation, it may be useful to exclude some

rooms (e.g. the bathroom) from the cooling function and to

actuate isolation valves especially for this. The heat pump

electronics system emits a signal that can be used for actu-

ating these.

A passive cooling module is also available as an alternative,

whereby heat energy is transported via underfloor heating,

for example, from the rooms to the ground without the com-

pressor operating and therefore without the refrigerant circuit

operating.

If required, the integrated electric back-up heater can be

activated at different output levels via the heat pump display.

The electric back-up heater is then actuated by the system

control.

3.2.2 Weather-compensated system control

The heat pump system is equipped with a weather-com-

pensated system control that provides the heating, cooling

and domestic hot water mode depending on the control type

and controls this in automatic mode.

The control changes the target flow temperature based on

the outdoor temperature. The outdoor temperature is meas-

ured by a separate sensor which is installed outdoors, and

the results are transmitted to the control. The room temper-

ature depends only on the preset values. The system com-

pensates for the effect of the outdoor temperature. Domestic

hot water generation is not affected by the weather com-

pensation. The instructions for the system control describe

how to install and operate the product.

3.2.3 Display of the energy consumption, energy

yields and efficiencies

The product, the system control and the app show approx-

imate values for energy consumption, energy yields and ef-

ficiencies, which are extrapolated based on calculation al-

gorithms.

The values that are displayed in the app may differ from the

other display options due to staggered transfer intervals.

The determined values depend on:

–Installation and system of the heating installation

–User behaviour

–Seasonal weather effects

–Various tolerances of unit-internal components

The recording of the values only includes the product in the

factory-delivered condition. Supplementary accessories,

even if they are installed on the product, as well as any other

components in the heating system and other external con-

sumers, are not part of the data recording.

Deviations between the determined values and the actual

values may be significant. The determined values are there-

fore not suitable for creating or comparing energy billing, for

example.

When replacing the PCB, the values for energy consump-

tion, energy yields and efficiencies are reset in the heat

pump's control panel.