Safety information and regulations

4ecoLEVEL installation and maintenance instructions 0020029316_01

2

The condensed water pump is not suitable for the pumping

of other fluids or solid media. In particular, waste water of

all types, chemicals and emulsions that contain oil must not

be fed into the condensed water pump. Using the con-

densed water pump in vehicles is regarded as improper use.

Units that are not classed as vehicles are those that are

installed in a fixed and permanent location (known as "fixed

installation").

Any other use, or use beyond that specified, shall be con-

sidered improper use. Any direct commercial or industrial

use is also deemed to be improper. The manufacturer/sup-

plier is not liable for any claims or damage resulting from

improper use. The user alone bears the risk.

Intended use includes observance of the operating and

installation and maintenance instructions and all other

applicable documents, as well as adherence to the mainte-

nance and inspection conditions.

Caution.

Improper use of any kind is prohibited.

2.2 General safety information

Working on the ecoLEVEL condensed water pump

The ecoLEVEL condensed water pump must only be

installed and started up by a competent person. The exist-

ing regulations, rules and guidelines must be observed

when doing so. Inspection/maintenance and repairs must

also be carried out by this skilled tradesman.

Only competent persons who have acquainted themselves

with all the safety information provided in these installation

instructions, and the fitting, operating and maintenance

instructions, may work on this unit.

Risk of electric shock when opening the unit and

carrying out maintenance work.

When operating this unit, certain components must inevita-

bly be under dangerous voltages which can lead to severe

bodily injury or to death.

>Ensure that the unit is only opened by a company oper-

ating a recognised competent persons scheme.

>Only open the bottom cover plate if all electrical connec-

tions to the pump have been isolated.

>Before carrying out any visual inspections and mainte-

nance work, ensure that the power supply is switched off

and secured against being switched back on again.

Risk of electric shock when the unit is switched on.

When operating this unit, certain components must inevita-

bly be under dangerous voltages which can lead to severe

bodily injury or to death.

>If measurements need to be made with the power supply

switched on, never touch the electrical connections.

>Remove all jewellery from wrists and fingers.

>Make sure that the test equipment is in a good, safe

operating condition.

>When working on the unit when it is switched on, ensure

that it is standing on an insulated base, in other words

make sure that there is no earth connection.

Risk of burns and explosion when unsuitable

liquids are used.

Pumping out flammable and explosive liquids such as pet-

rol, heating oil, etc., poses a risk of burns and explosions.

>Do not use the pump to pump out flammable or explo-

sive liquids.

Risk of explosions in explosive atmospheres.

Operating the pump in explosive atmospheres could trigger

an explosion.

>Do not use the pump in an explosive atmosphere.

Risk of injury due to condensate.

The condensate pumped by the pump poses a risk to the

eyes if they come into contact with it.

>Avoid any contact of the condensed water with the eyes.

>Make sure that the ecoLEVEL condensed water pump is

only operated out of the reach of children.

>In case of eye contact with the condensate, rinse the

eyes thoroughly with clean water and seek medical

advice.

Danger of poisoning by flue gas leaks.

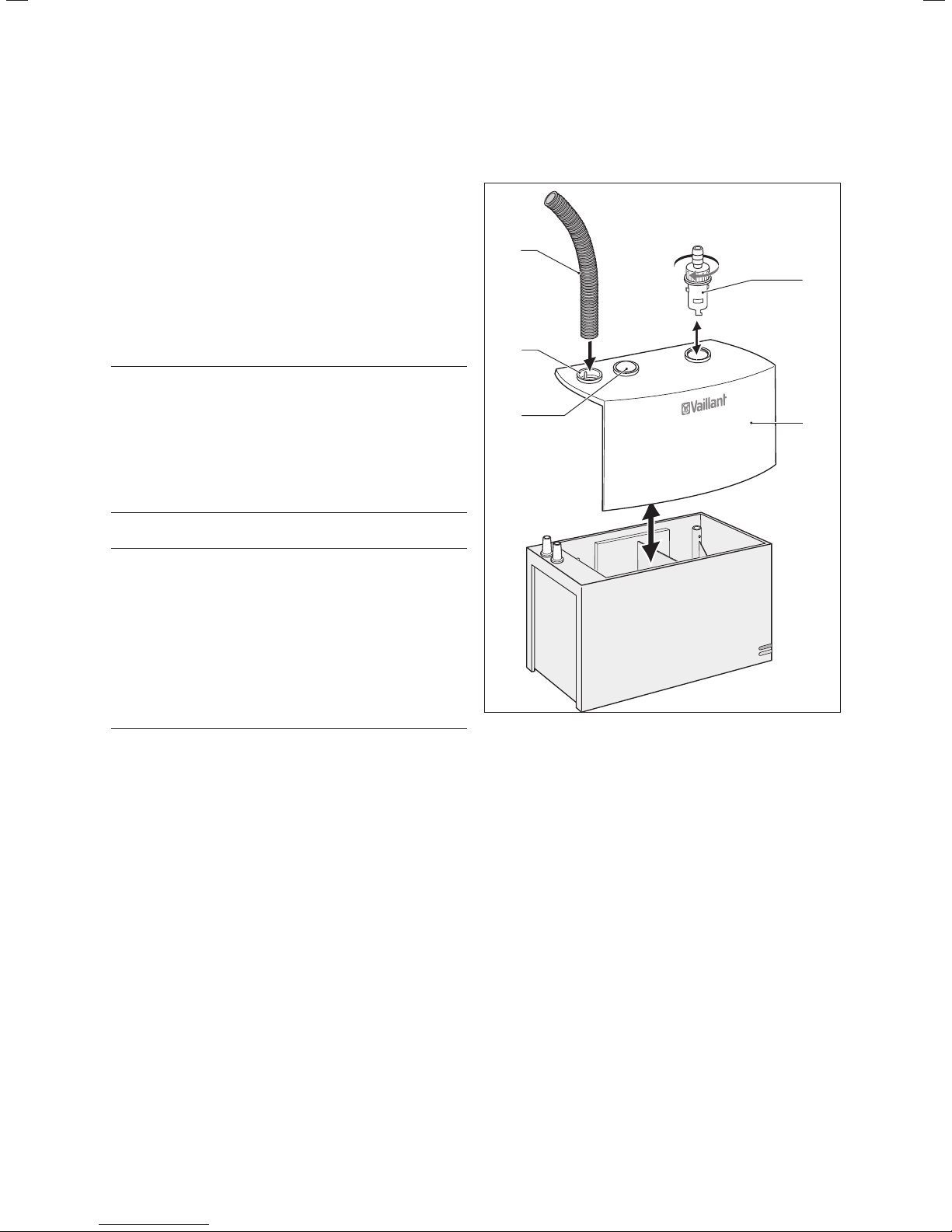

If you connect the condensate drain hose of the pump with

the waste water piping, the internal siphon of the boiler

may be completely emptied.

>Do not connect the water condensate hose of the pump

with a sealed connection to the waste water piping ('free

outlet').

Malfunctions and material damage due to

instability.

If the pump is not in a stable position during operation, this

can lead to malfunctions of the pump. This may result in

damage to the pump or boiler.

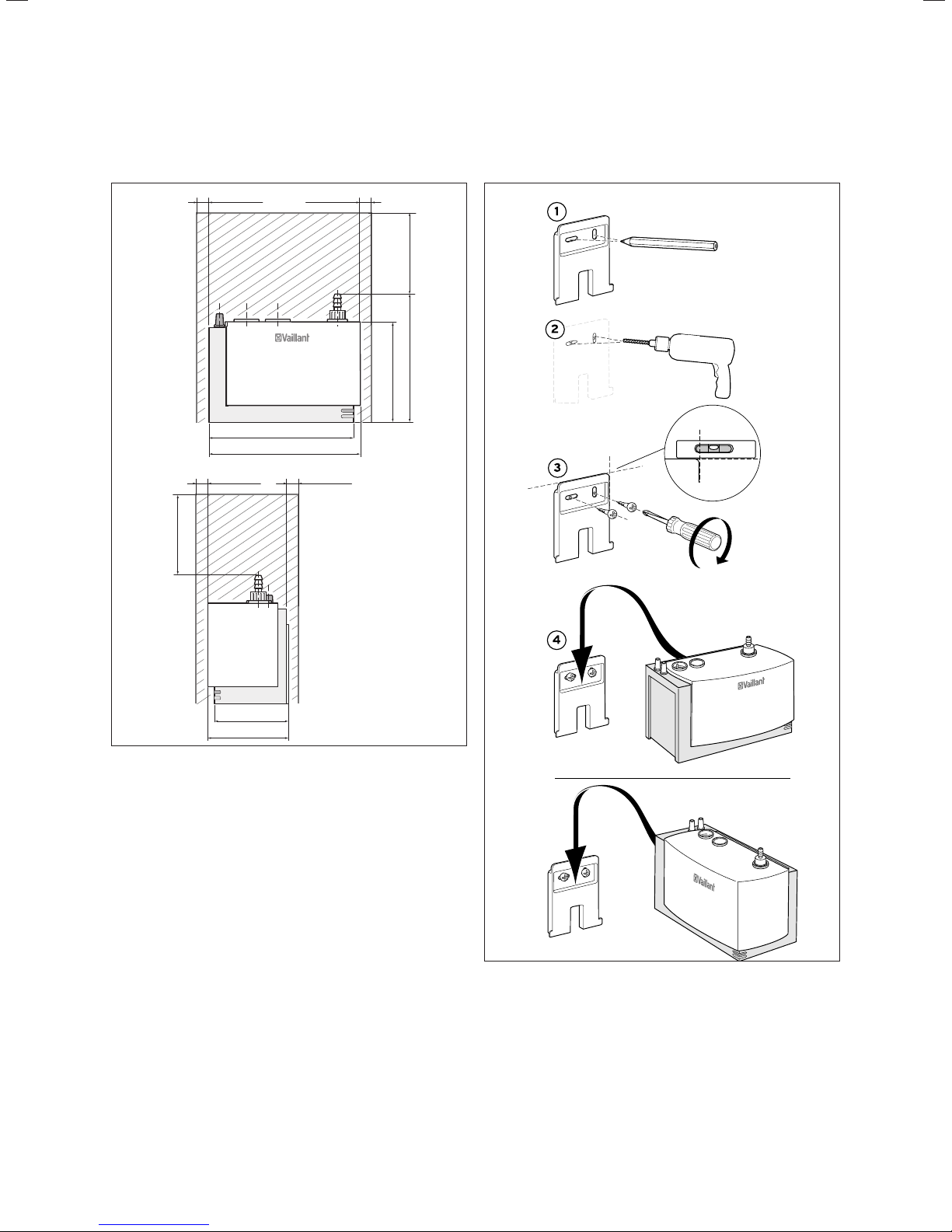

>During operation, ensure that the pump has a stable

base or is attached to the wall.

Risk of damage due to improper modifications.

Modifications to the ecoLEVEL condensed water pump may

damage the unit and are therefore generally prohibited.

>Under no circumstances should you ever attempt to make

alterations to the pump or other parts of the system.

>Consult an approved heating specialist company to make

such alterations.

Material damage caused by leaking condensed

water

In the event of a defect in the condensed water pump, leak-

ing condensed water may cause material damage or dam-

age to the boiler.

>Connect a current interrupter or an alarm to the safety

cut-out switch.