________________________________________________________________________________

VAISALA ________________________________________________________________________ 1

Table of Contents

CHAPTER 1

GENERAL INFORMATION............................................................................ 3

About This Manual ................................................................... 3

Contents of This Manual ....................................................... 3

Version Information ............................................................... 4

Related Manuals ................................................................... 4

General Safety Considerations ............................................. 4

Feedback............................................................................... 5

Product Related Safety Precautions ...................................... 5

Recycling .................................................................................. 5

Warranty.................................................................................... 6

CHAPTER 2

PRODUCT OVERVIEW.................................................................................. 7

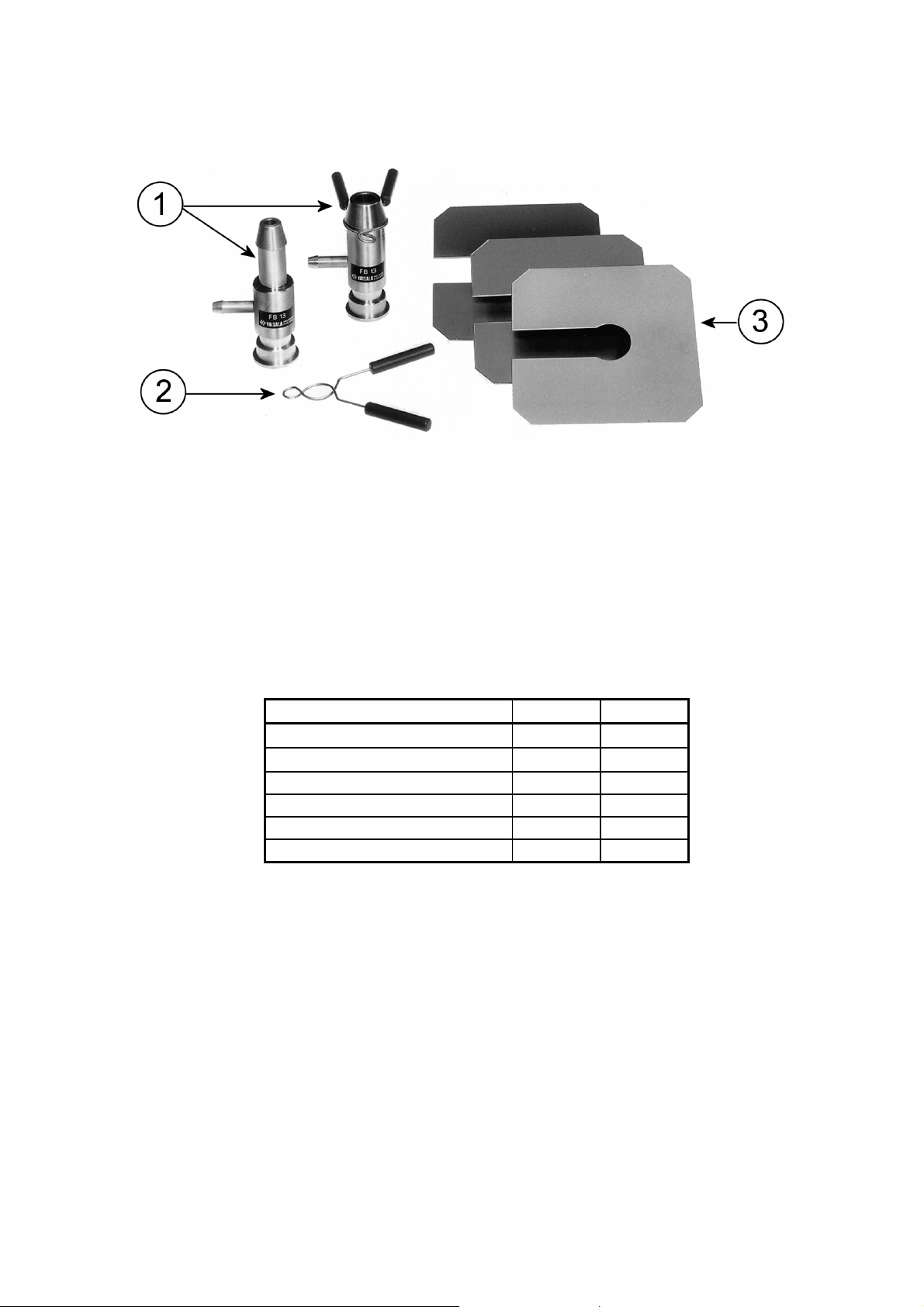

Introduction to Vaisala Filling Balance FB13 ........................ 7

CHAPTER 3

OPERATION................................................................................................. 11

Regulations for Balloon Filling Sheds ................................. 11

Treatment of the Balloon before Inflation............................ 12

Storage................................................................................ 12

Low Altitude Burst ............................................................... 12

Selecting the Filling Balance Weight ................................... 13

Filling the Balloon .................................................................. 14

CHAPTER 4

TROUBLESHOOTING ................................................................................. 15

Troubleshooting Procedure .................................................. 15

Technical Support .................................................................. 15

APPENDIX A

SAFETY INSTRUCTIONS FOR BALLOON OPERATORS ........................ 17