Contents

1 Introduction..................................................................................................................................1

2 Specifications ..............................................................................................................................2

2.1 Sensor Specifications ...........................................................................................................2

2.1.1 Sound Velocity.................................................................................................................2

2.1.2 Conductivity .....................................................................................................................2

2.1.3 Pressure...........................................................................................................................2

2.1.4 Temperature ....................................................................................................................2

2.2 Mechanical Specifications ....................................................................................................3

2.2.1 Materials ..........................................................................................................................3

2.2.2 Connectors.......................................................................................................................3

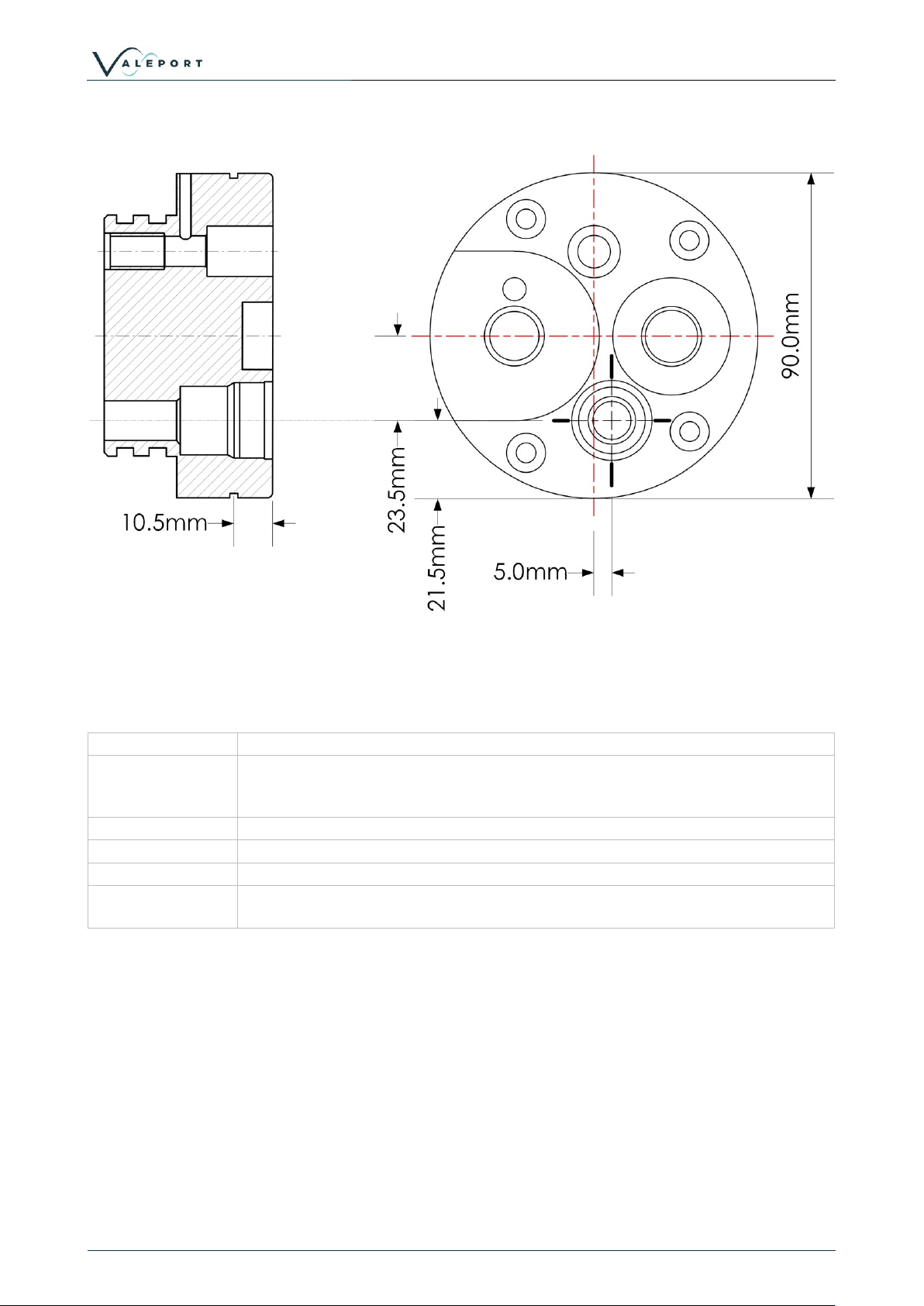

2.2.3 Dimensions ......................................................................................................................4

2.3 Performance Specifications..................................................................................................5

2.4 Sample Battery Life Calculations .........................................................................................6

2.4.1 Based on Memory............................................................................................................6

2.4.2 Based on Batteries ..........................................................................................................8

3 Installation .................................................................................................................................10

3.1 Communications With a PC................................................................................................10

3.2 Deploying the MIDAS SVX2 ...............................................................................................10

3.2.1 Real Time Operation......................................................................................................10

3.2.2 Self Recording Operation ..............................................................................................11

3.2.3 LED Flashing Sequence................................................................................................11

3.2.4 Real Time Data Formats ...............................................................................................11

3.3 Data Download ...................................................................................................................12

4 Maintenance ..............................................................................................................................13

4.1 Changing Batteries .............................................................................................................13

4.1.1 Removing the End Cap Safely ......................................................................................14

4.2 Seals ...................................................................................................................................14

4.2.1 O-Rings..........................................................................................................................15

4.2.2 Anti-Extrusion Rings ......................................................................................................15

5 Wiring Information .....................................................................................................................16

5.1 Switch Plug .........................................................................................................................16

5.2 3m Y Lead (RS232)............................................................................................................16

5.3 3m Switched Y Lead (RS485) ............................................................................................17

6 Frequently Asked Questions .....................................................................................................18

7 EU Declaration of Conformity - CE Marking .............................................................................21