1Product Overview ..................................................................................................3

2Installing and connecting the controller.................................................................3

2.1 Safety...............................................................................................................3

2.2 Overview.........................................................................................................4

2.2.1 Connecting the FFC ribbon cables...........................................................4

2.2.2 Basic installation overview –LP12 .........................................................5

2.2.3 Configuration menu and tuning software ................................................6

2.2.4 Configuration menus and parameters - introduction ...............................7

2.2.5 Setup Menu - item entry ..........................................................................7

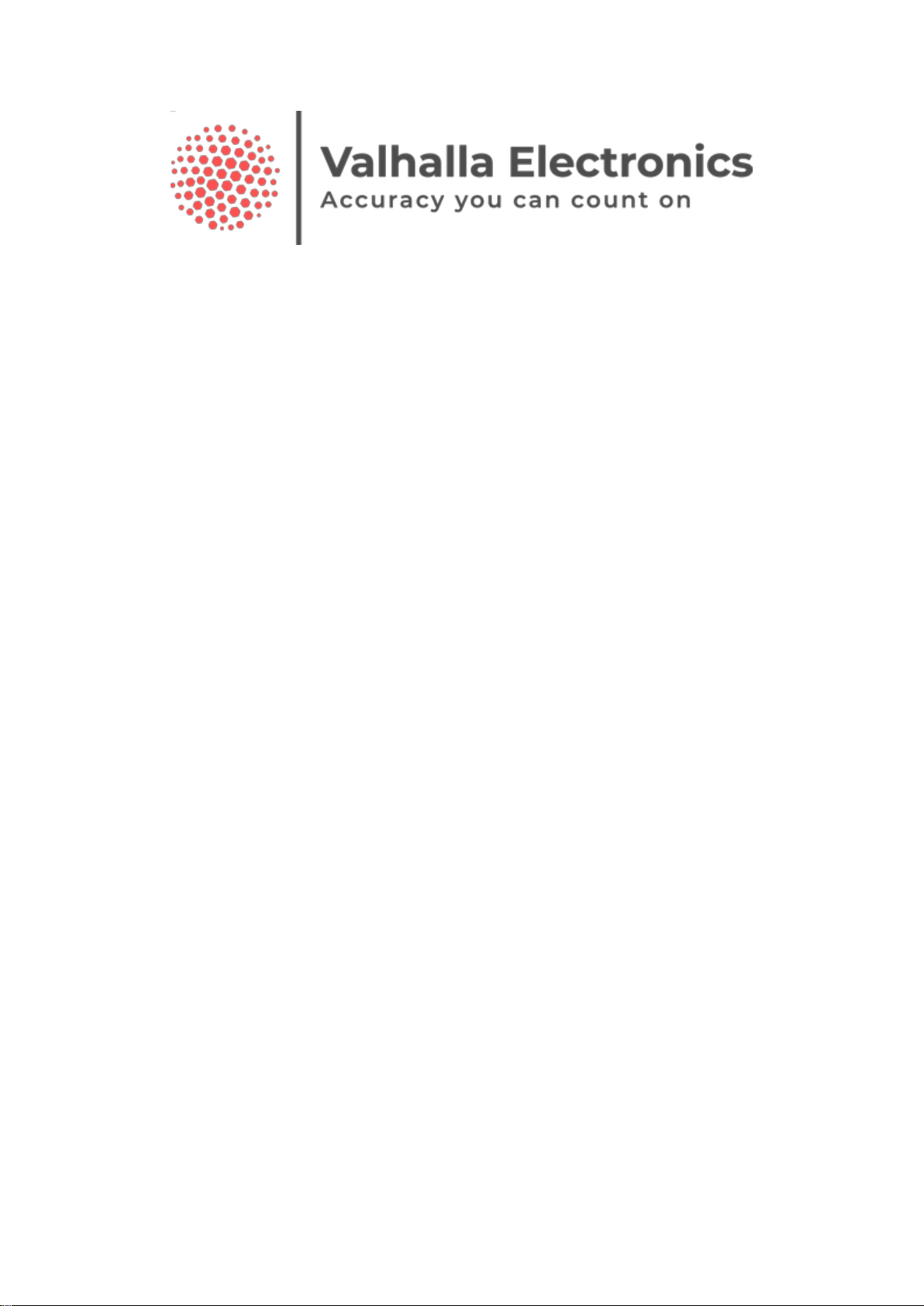

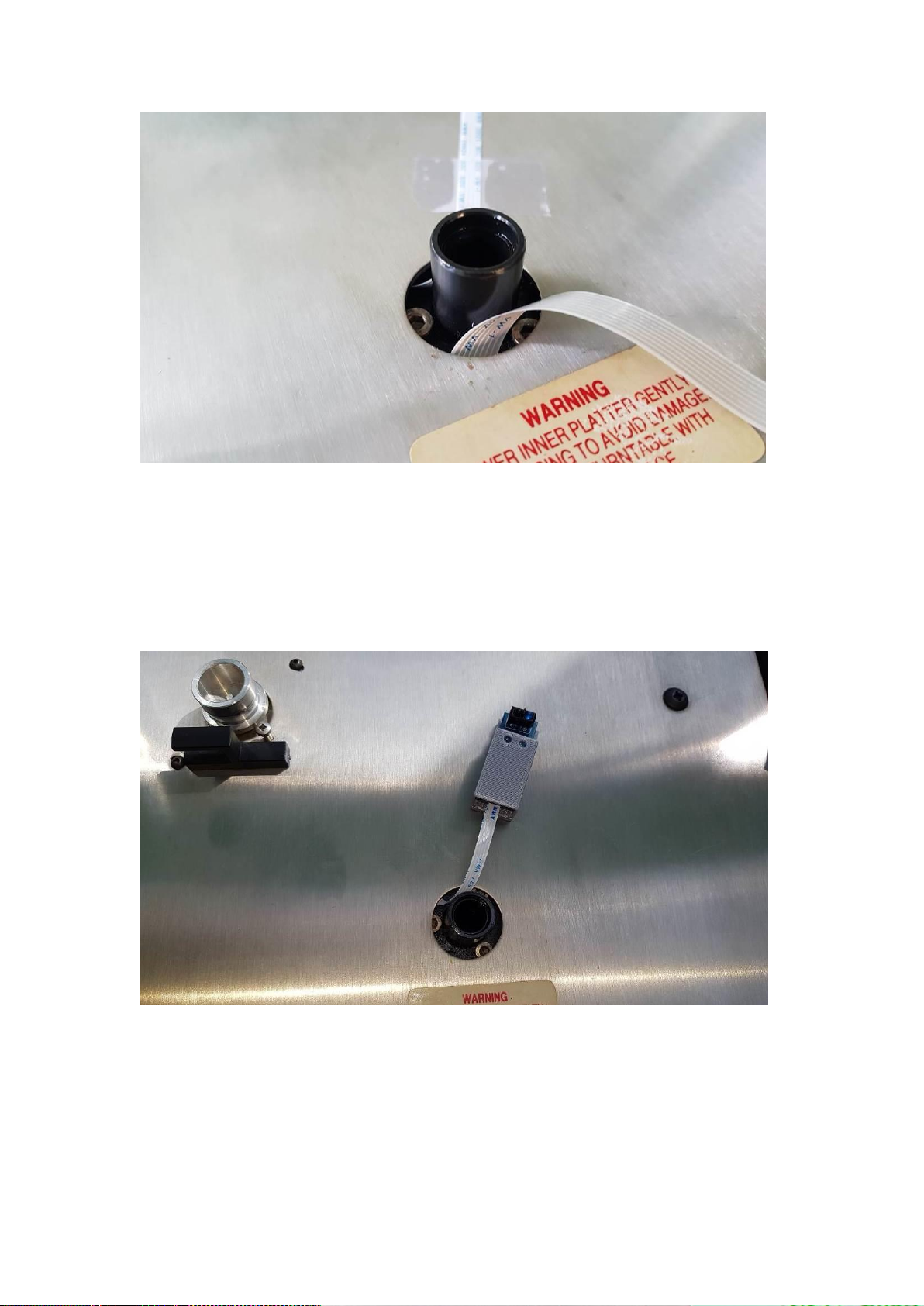

2.3 Mounting the platter internal IR sensor –LP12..............................................7

2.4 Mounting OLED Display –LP12 .................................................................10

2.5 Adaptive Speed Control –PID......................................................................12

2.5.1 Turntable PID values .............................................................................12

2.5.2 Final installation note.............................................................................13

3Configuration menus and parameters ..................................................................14

3.1.1 Setup Menu - item entry ........................................................................14

3.1.2 System Parameters.................................................................................14

3.1.3 Motor Parameters...................................................................................16

3.1.4 PID Control parameters .........................................................................16

3.1.5 Test platter Sensor Trigger.....................................................................17

3.1.6 RequestedvsProgrammed Values...........................................................17

3.1.7 Write to eeprom .....................................................................................17

3.1.8 Motor ON/OFF ......................................................................................17

3.2 PID Tuning - Theory.....................................................................................18

3.3 Step response.................................................................................................19

3.4 Stability in the time domain..........................................................................19

3.4.1 Analysing step response plots................................................................20

3.5 Tutorial –Manually tuning from scratch ......................................................22

4Appendix - MAC Users.......................................................................................26

5Specifications.......................................................................................................28

6Manufacturer Details ...........................................................................................28