13C50-0165 - Stationary Vertical Mixer V-Mix 280 Standard - March 2016

8

near the top of the mixer while it is in operation� The rotating

vertical auger(s) armed with knives will cut or sever resulting

in death or severe injury to anyone who should come in contact

with the vertical auger(s) while the machine is in operation�

5� Do not allow inexperienced or unqualified persons to operate

the mixer� Keep bystanders away from equipment while it is

in operation� Keep children a safe distance away� Operators

of the Stationary Vertical Mixer must use common sense at all

times�

6� Do not wear loose or floppy clothing while operating the Sta-

tionary Vertical Mixer� Loose clothing may become entangled

in moving parts or moving machinery and cause severe injury

or death�

7� Know the location and function of the master electrical shut-

down should the need arise

8� Should a problem occur during operation of the Stationary

Vertical Mixer, turn OFF motor, lock out power at master power

panel and wait for all moving parts to stop before servicing,

adjusting or repairing�

9� Use caution when working around the discharge area� Never

reach in, around, or over the discharge door(s)� Never place

hands in any opening when in operation�

10� Never hand feed materials into mixer while it is running� Pivo-

ting augers with knives may cut or grab hands or clothing,

causing severe injury�

11� Never operate machine with a cracked, bent, missing or broken

knife�

12� Review safety instructions with all operators annually�

2.3 MAINTENANCE SAFETY

1� Follow ALL the operating, maintenance and safety informa-

tions in the manual�

2� Follow good Shop Practices:

• Keep service area clean and dry�

• Be sure electrical outlets and tools are properly grounded�

• Use adequate light for the job at hand�

3� Always turn OFF motor, lock out power at master power panel

and wait for all moving parts to stop before servicing, adjus-

ting, repairing or unplugging�

4� If work must be performed inside the mixer, put a protective

cover over the knives�

5� Use caution when stepping inside the tub, floor might be slip-

pery�

6� Keep hands, feet, hair and clothing away from moving and/or

rotating parts�

7� Never wear ill-fitting, baggy or frayed clothing when working

around or on any of the drive system components�

2.4 ELECTRICAL SAFETY

1� Have a qualified electrician to connect power to the machine�

2� Keep electrical wires and connections in good repair�

3� Maintain a dry working area�

2.5 INSTALLATION SAFETY

1� Use only a hoist, crane or forklift with sufficient lifting capa-

city and stability to handle the machine�

2� Have 2 men available to maneuver the unit when lifting,

moving or installing�

3� Have a qualified electrician to connect power to the machine�

2.6 STORAGE SAFETY

1� Store the Stationary Vertical Mixer on a firm, level surface�

2� Store away from areas of human activity�

3� Do not permit children to play on or around the stored ma-

chine�

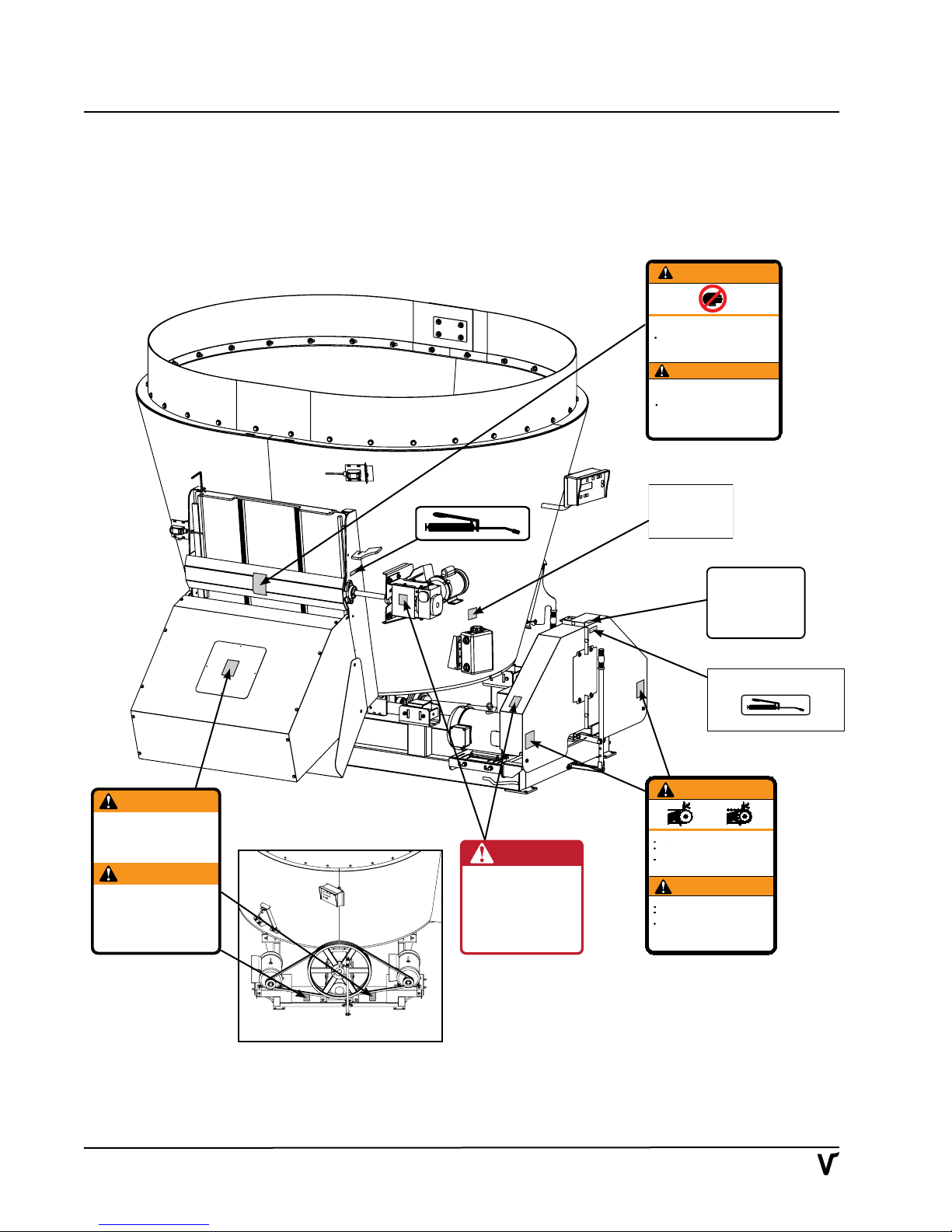

2.7 SAFETY DECALS

1� Keep safety decals and signs clean and readable at all times�

2� Replace safety decals and signs that are missing or have be-

come illegible�

3� Replaced parts that displayed a safety sign should also display

the current sign�

4� Safety decals or signs are available from your Dealer Parts De-

partment or the factory�

How to install Safety DecaIs:

• Be sure that the installation area is clean and dry�

• Decide on the exact position before you remove the backing

paper�

• Remove the smallest portion of the split backing paper�

• Align the decal over the specified area and carefully press the

small portion with the exposed sticky backing in place�

• Slowly peel back the remaining paper and carefully smooth the

remaining portion of the decal in place�

• Small air pockets can be pierced with a pin and smoothed out

using the piece of decal backing paper�