VALSTEAM

ADCA

We reserve the right to change the design and material of this product without notice.

IMI 1.335 E 03.14

INSTALLATION AND MAINTENANCE INSTRUCTIONS

FLOAT & THERMOSTATIC STEAM TRAPS

FLT17

GENERAL

•These instructions must be carefully read before any work involving products supplied by VALSTEAM ADCA

ENGINEERING S.A. is undertaken.

•The installation procedure is a critical stage in a life of a steam trap and care should be taken to avoid damage

to the trap or equipment.

Warning!

- At start up, the presence of small particles in the water (dirt, scale, weld splatters, etc) may cause an imperfect

closure of the seat. If this occurs, proceed to an accurate cleaning.

- Do not touch the equipment without appropriate protection during working operation because it may conduct heat

if the used fluid is at high temperature.

- Before starting maintenance be sure that the equipment is not pressurized or hot.

- The equipments must be used within the working temperature and pressure limits laid down for them, otherwise

they may fail (refer to nameplate and/or IS- Information Sheet).

- Do not remove the nameplate attached to the equipment. Serial number and other useful information is stamped

on it.

INSTALLATION

- Before to install remove plastic covers placed on flanges or connection ends. The equipment has an arrow or

Inlet/Outlet designations. Be sure that it will be installed on the appropriate direction.

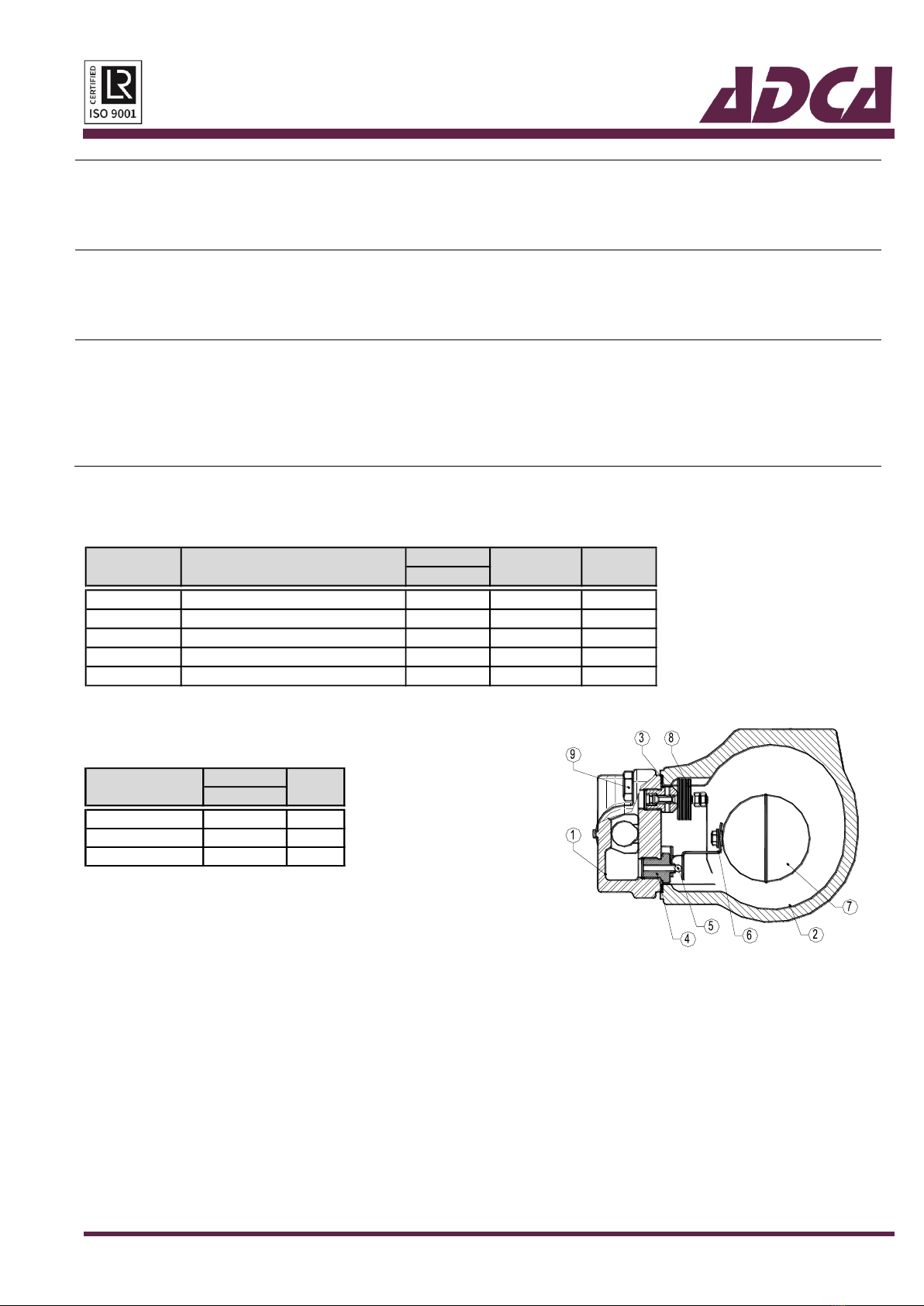

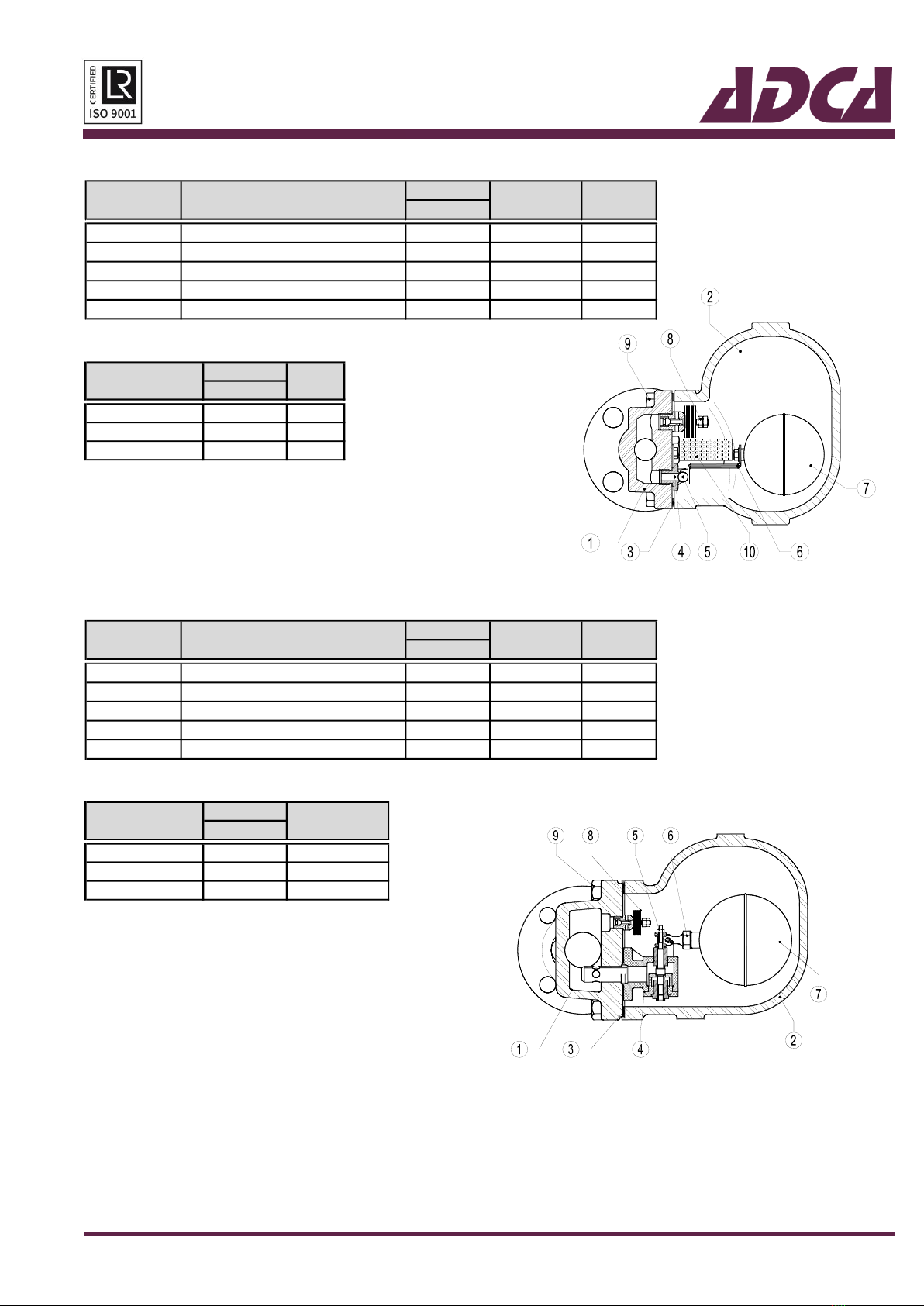

- Install the steam trap in the point of the system, where the condensate tends to collect. It must be installed with the

float lever in horizontal plane, so that it rises and falls vertically. An ADCA strainer should be installed upstream of

the trap.