Operation and configuration

VAMP 24h support phone +358 (0)20 753 3264

Table of Contents

1. General ...................................................................................4

1.1. Relay features.....................................................................4

1.2. User interface......................................................................5

1.3. Operating Safety................................................................5

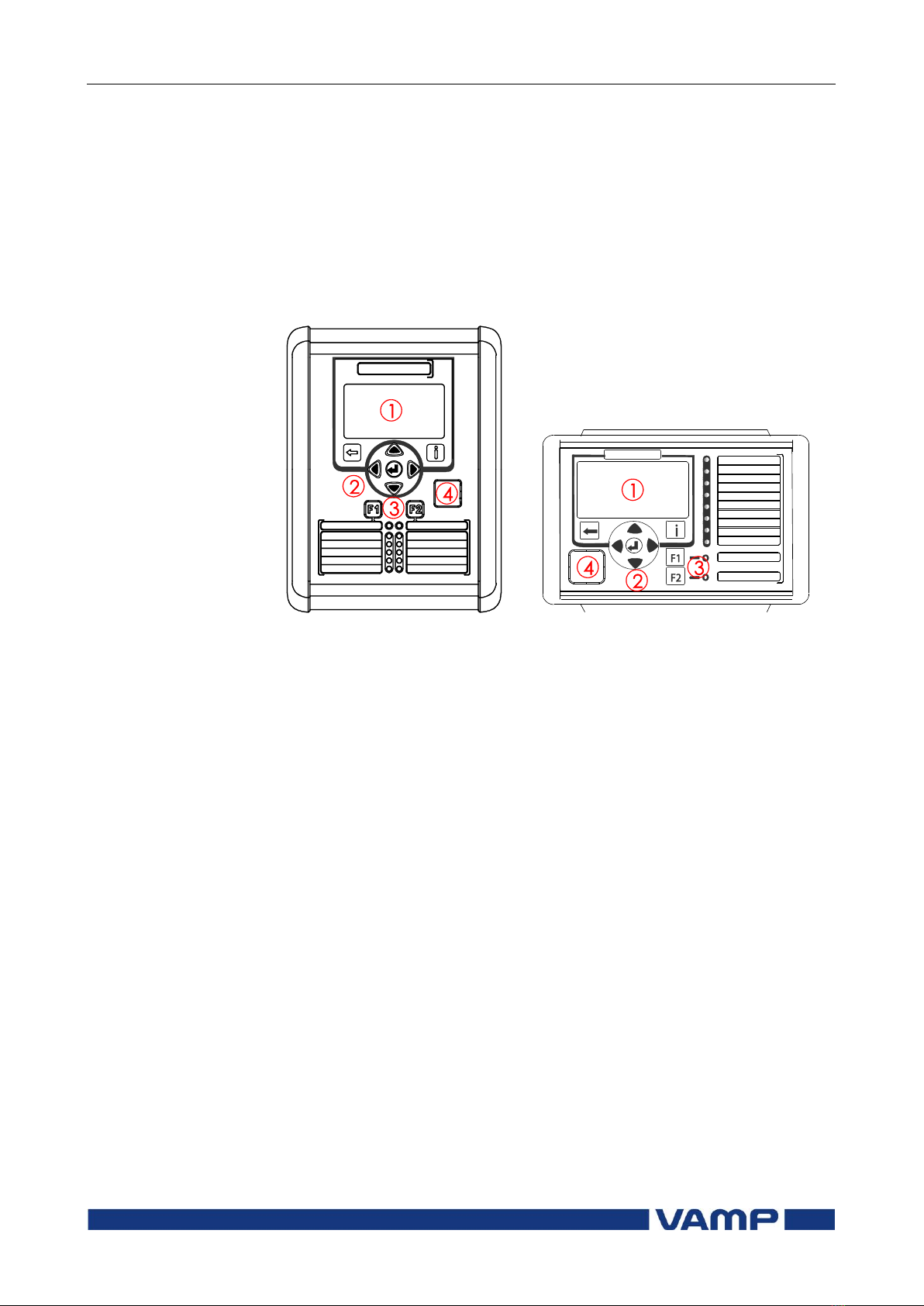

2. Local panel user interface ....................................................6

2.1. Relay front panel................................................................6

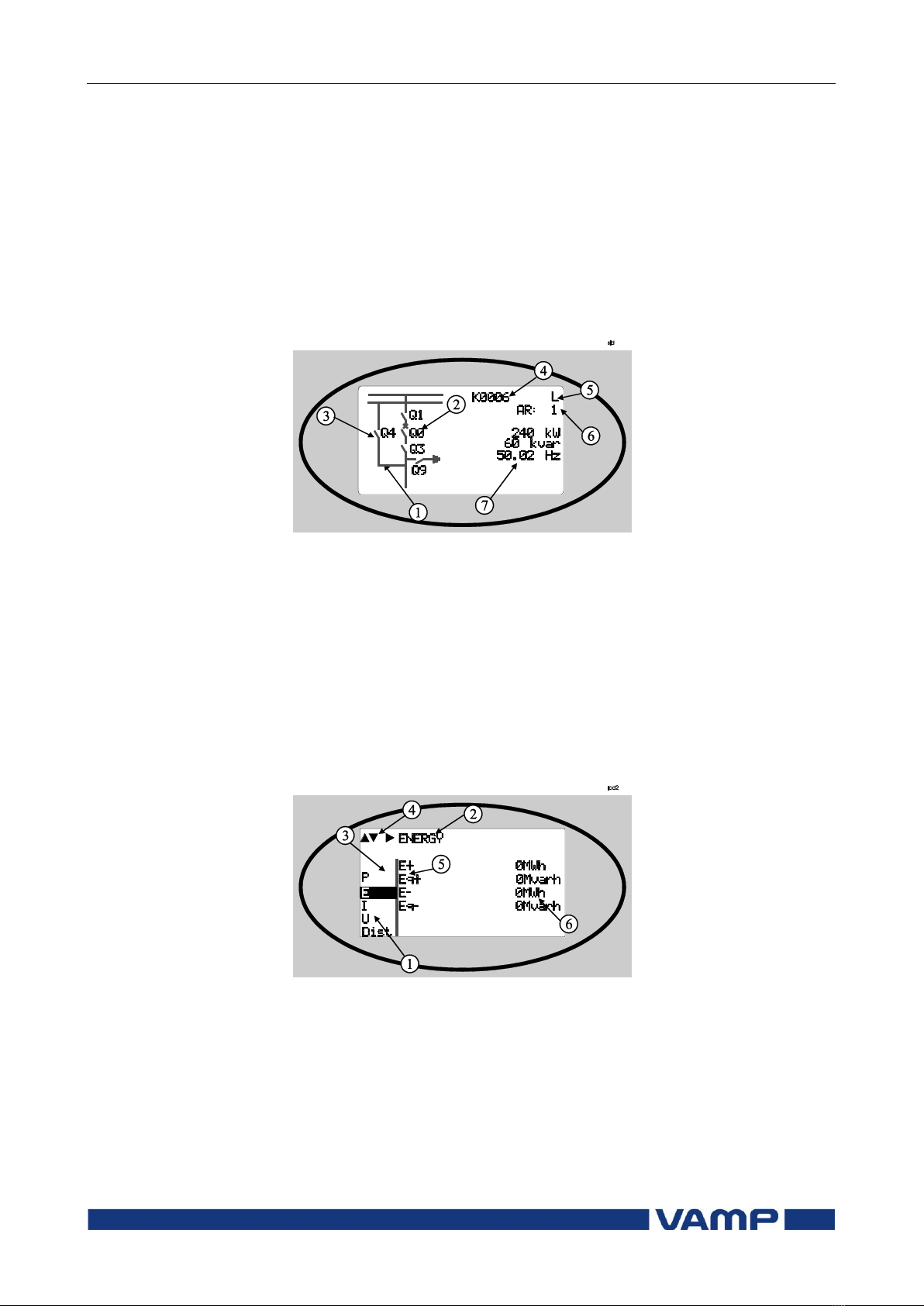

2.1.1. Display .........................................................................7

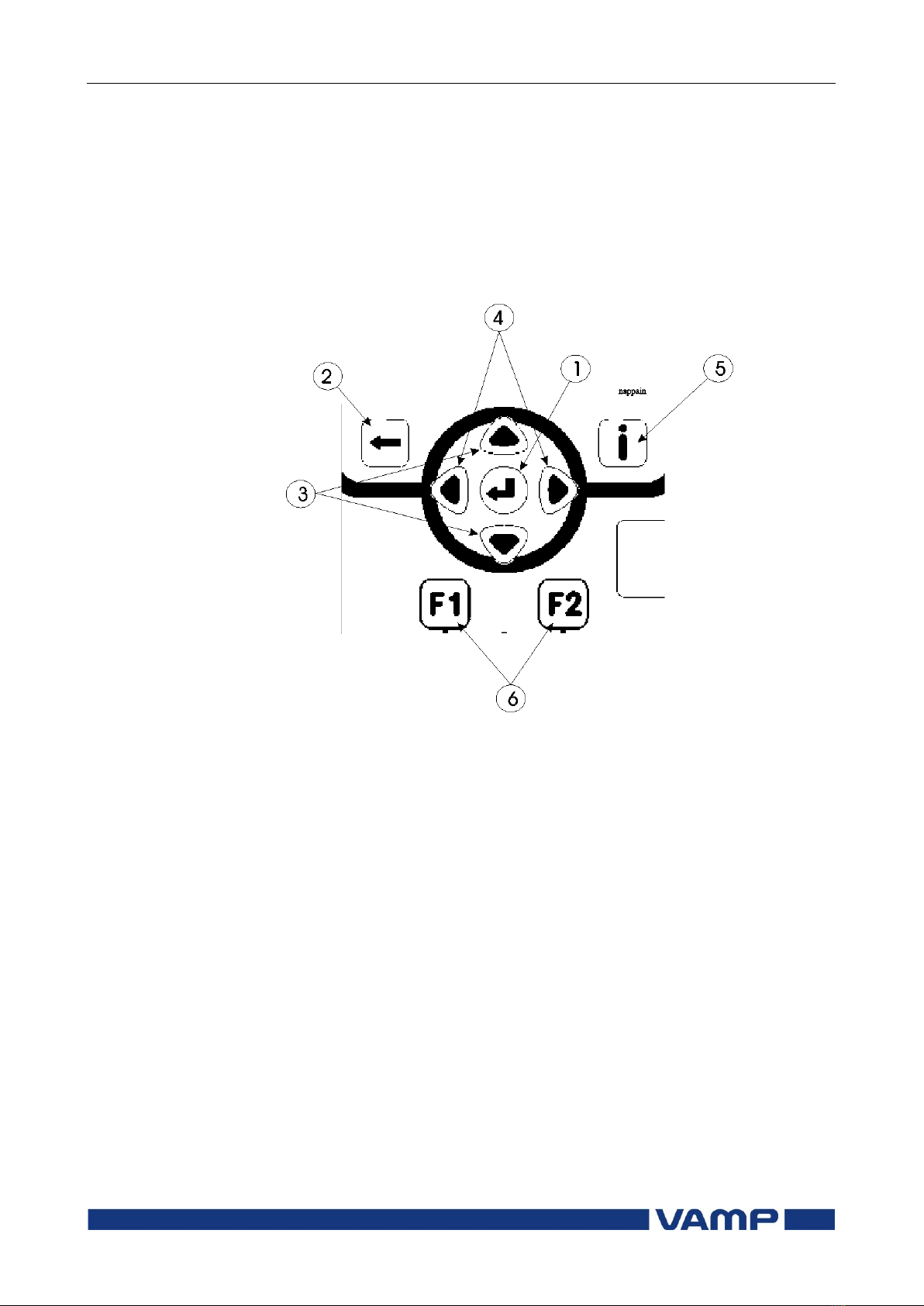

2.1.2. Menu navigation and pointers................................8

2.1.3. Keypad........................................................................9

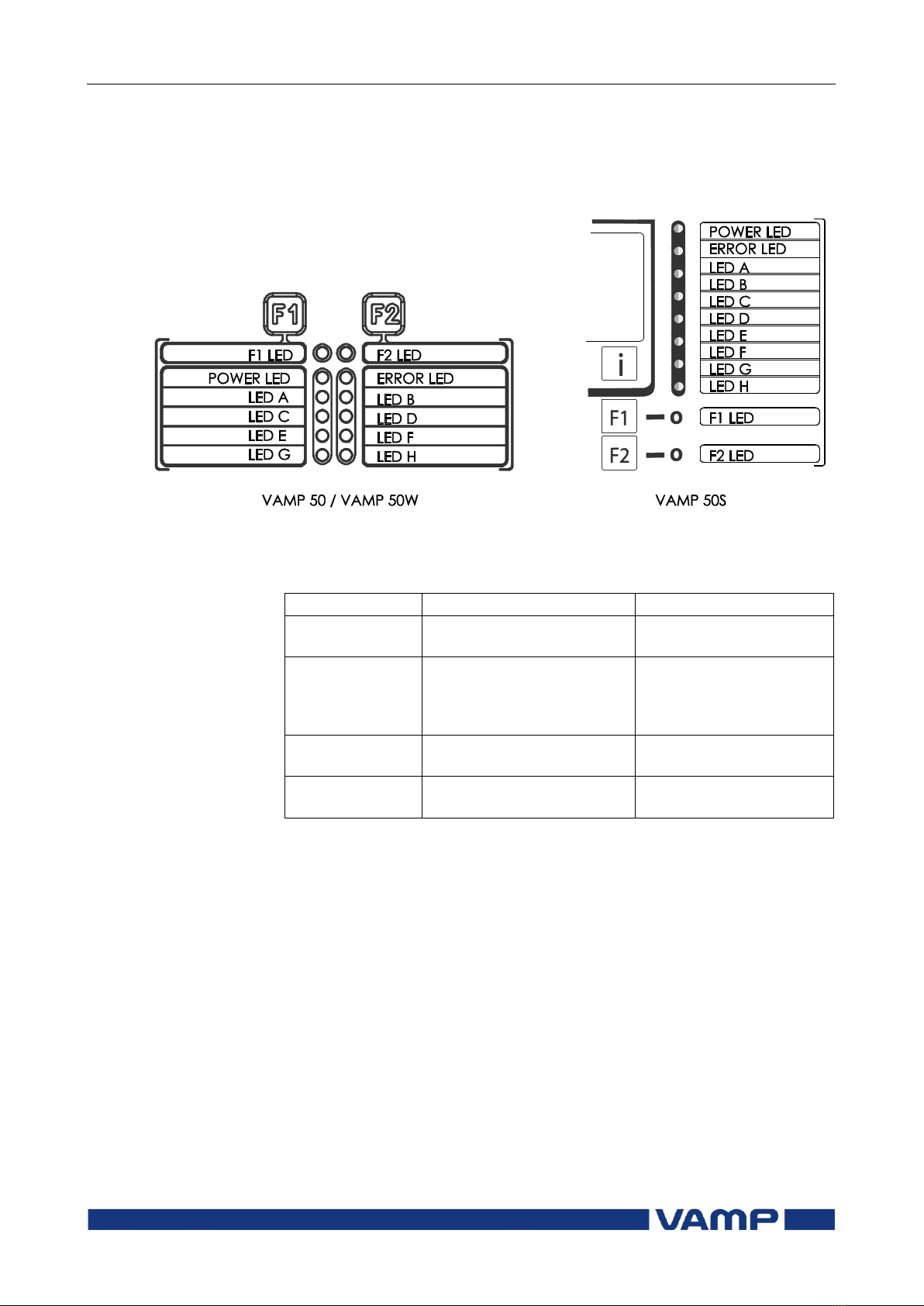

2.1.4. Operation indicators .............................................. 10

2.1.5. Adjusting display contrast ..................................... 11

2.2. Local panel operations .................................................. 11

2.2.1. Navigating in menus .............................................. 11

2.2.2. Menu structure of protection functions .............. 14

2.2.3. Setting groups ......................................................... 18

2.2.4. Fault logs .................................................................. 19

2.2.5. Operating levels...................................................... 20

2.3. Operating measures....................................................... 22

2.3.1. Control functions .................................................... 22

2.3.2. Measured data ....................................................... 23

2.3.3. Reading event register .......................................... 24

2.3.4. Forced control (Force)........................................... 25

2.4. Configuration and parameter setting ......................... 26

2.4.1. Parameter setting ................................................... 27

2.4.2. Setting range limits ................................................. 28

2.4.3. Disturbance recorder menu DR ........................... 28

2.4.4. Configuring digital inputs DI.................................. 29

2.4.5. Configuring digital outputs DO ............................ 29

2.4.6. Configuring analogue outputs AO (Option)...... 30

2.4.7. Protection menu Prot ............................................. 30

2.4.8. Configuration menu CONF ................................... 31

2.4.9. Protocol menu Bus.................................................. 32

2.4.10.Single line diagram editing ................................... 35

2.4.11.Blocking and interlocking configuration............. 35

3. VAMPSET PC software ..........................................................36