User manual

User manual

greenpin.com

Green Pin Tycan

®

Lashing Chain

• If at any place on the exterior layer of the link leg has been torn,

cut or abraded all the way through (in one or more places),

and the length of the cut(s) (individually or accumulated)

is longer than 80% of the link-width, Green Pin Tycan

®

Lashing Chain must be removed from service immediately

and shall be destroyed and not used for any application.

• If at any place on the exterior layer of the link are torn, cut

or abraded away more than 50% trough, and the area(s)

is longer than 160% of the link width, Green Pin Tycan

®

Lashing Chain must be removed from service immediately

and shall be destroyed and not used for any application.

• If there are visible cuts or abrasion of more than 1mm deep,

across all numbers of layers on the side of the link leg, Green Pin

Tycan

®

Lashing Chain must be removed from service immediately

and shall be destroyed and not used for any application.

• If there are visible cuts or abrasion of more than 2mm deep, across

more than 75% of numbers of layers on the side of the link leg,

Green Pin Tycan

®

Lashing Chain must be removed from service

immediately and shall be destroyed and not used for any application.

• If there are visible cuts or abrasion of more than 3mm deep, across

more than 50% of numbers of layers on the side of the link leg,

Green Pin Tycan

®

Lashing Chain must be removed from service

immediately and shall be destroyed and not used for any application.

• If there are visible cuts or abrasion of more than 4mm deep,

across two layers or more on the side of the link leg, Green Pin

Tycan

®

Lashing Chain must be removed from service immediately

and shall be destroyed and not used for any application.

• If stitching is torn/ abraded to the extent that the layers of

webbing can unravel,

Green Pin Tycan

®

Lashing Chain

must be

removed from service immediately and shall be destroyed and not

used for any application.

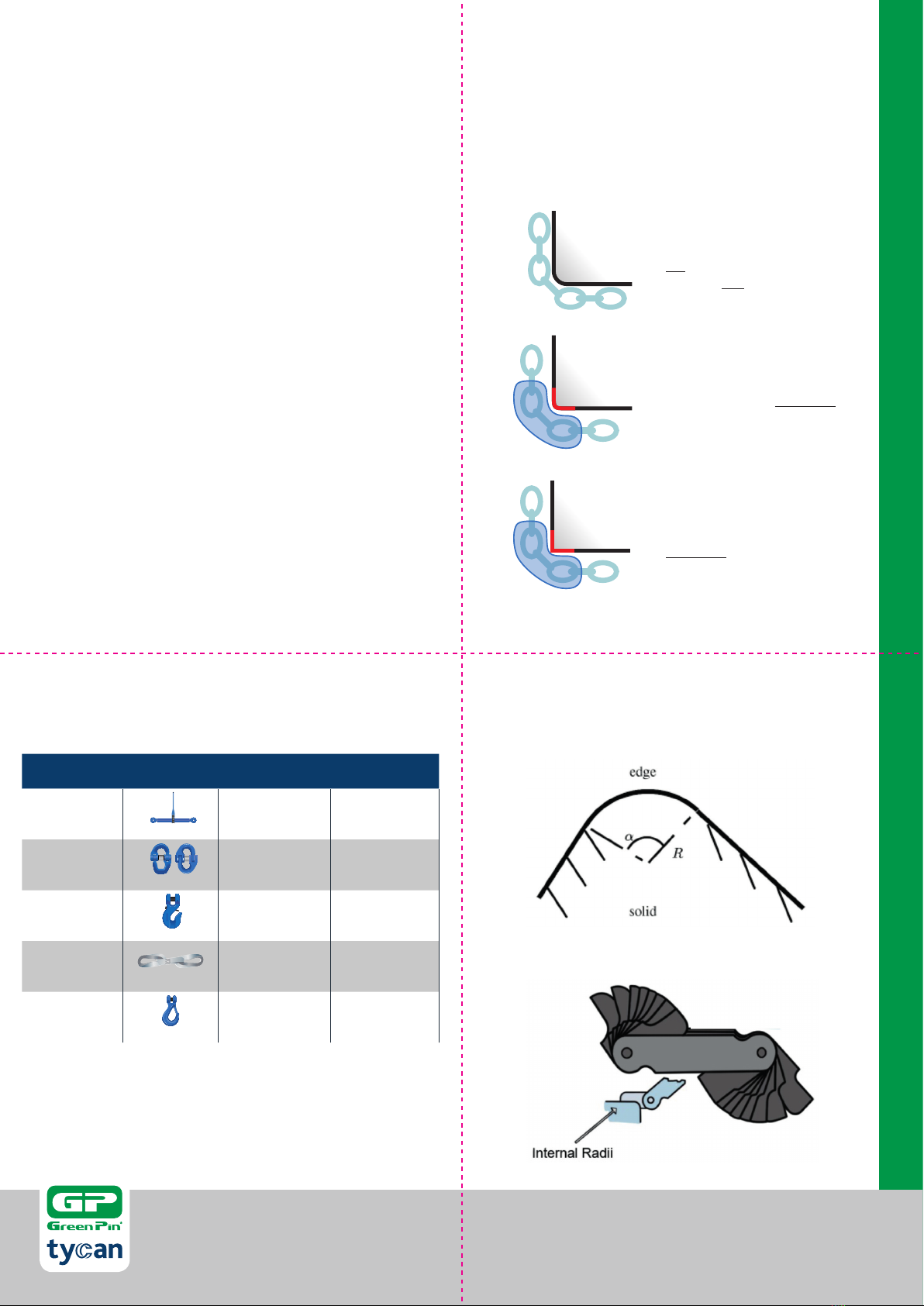

Connecting Green Pin Tycan

®

Lashing Chain directly into hooks

(components) where the width/clevis

is more than required minimum clevis

width is not acceptable. Doing so

can cause the layers to spread apart,

which in the utmost consequence

could have a negative effect on

the strength of the chain. The only

exception is when it is not an open

end-link and both load bearing-points

of the link is under tension from the

adjacent chain links. An example

of this is the anchored basket hitch

showed in this manual.

Storage

• Storage area should be clean, dry, dark and free of mechanical and

environmental damage.

• Storage temperature should be no more than +70 degrees Celsius

(158°F) for short term storage (less than one week) and no more

than +30 degrees Celsius (86°F) for long term storage.

Inspection and Removal from Service Criteria

Inspect individual Chain Links thoroughly before each use for

abrasion, tears, cuts or other damage which might affect the

performance of Green Pin Tycan

®

Lashing Chain.

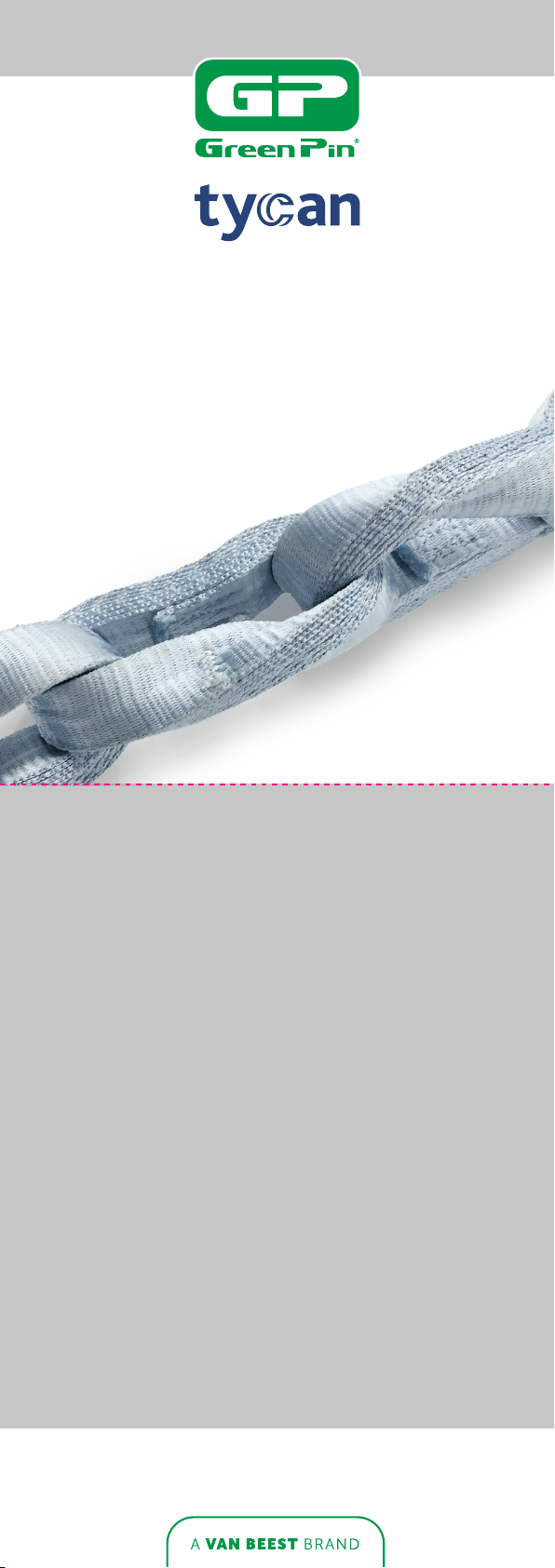

Link

Bearing

Point

Interface

Link Leg

Details wear/tear damage

The pictures show defined areas of

Green Pin Tycan

®

Chain Link, such

as the Link Leg and Interface. Which

allows for dierent amounts of wear

and tear:

• Zero tolerance for damage allowed

in Link Bearing Point.

• No folding or spreading out of

layers allowed in Link Bearing

Point.