Table of Contents

Foreword ...................................................................................................................................... 2

Table of Contents .......................................................................................................................... 3

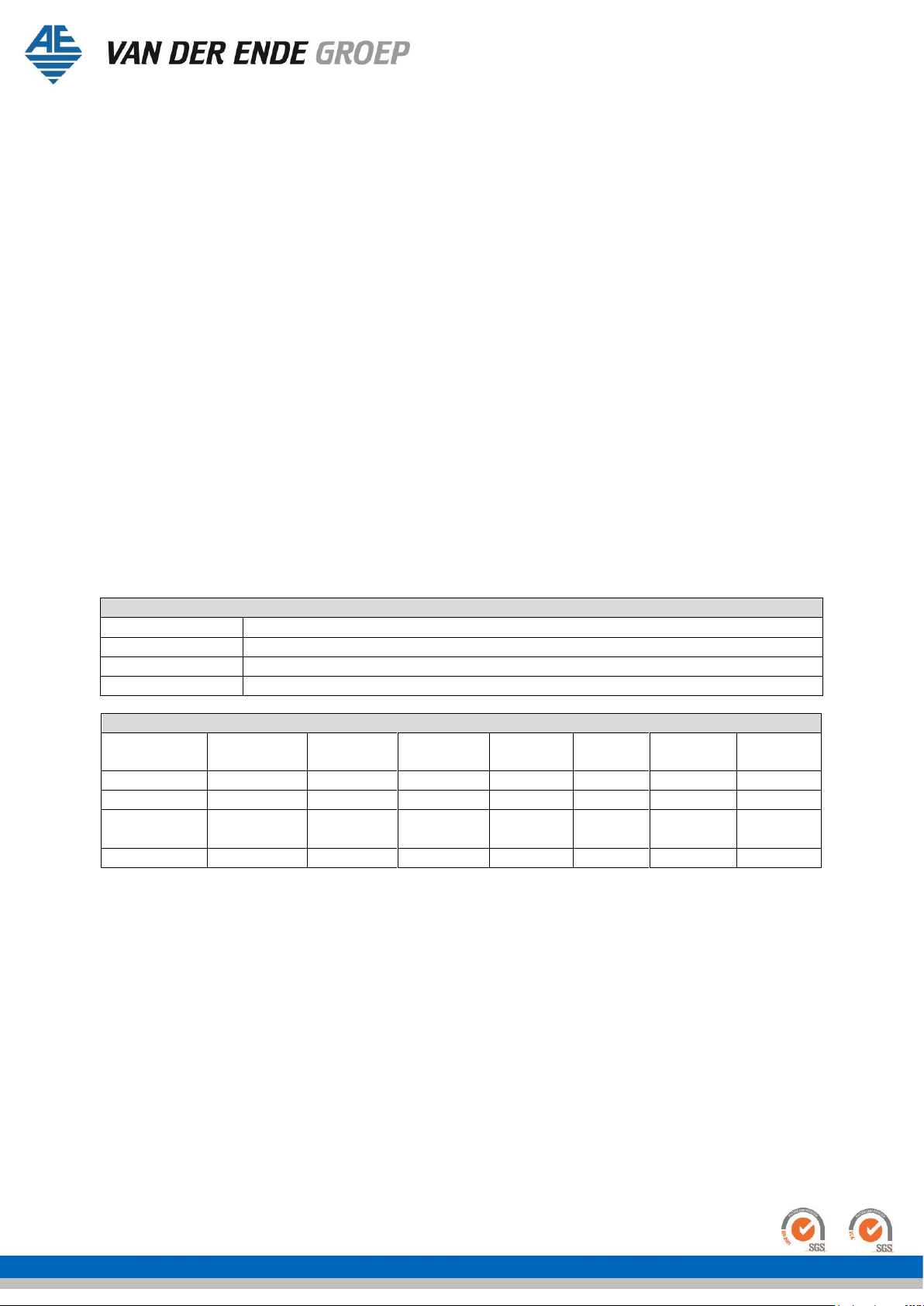

1Identification .......................................................................................................................... 4

1.1 General .......................................................................................................................... 4

1.1.1 Description of the machine .......................................................................................... 4

1.1.2 Specifications.............................................................................................................. 4

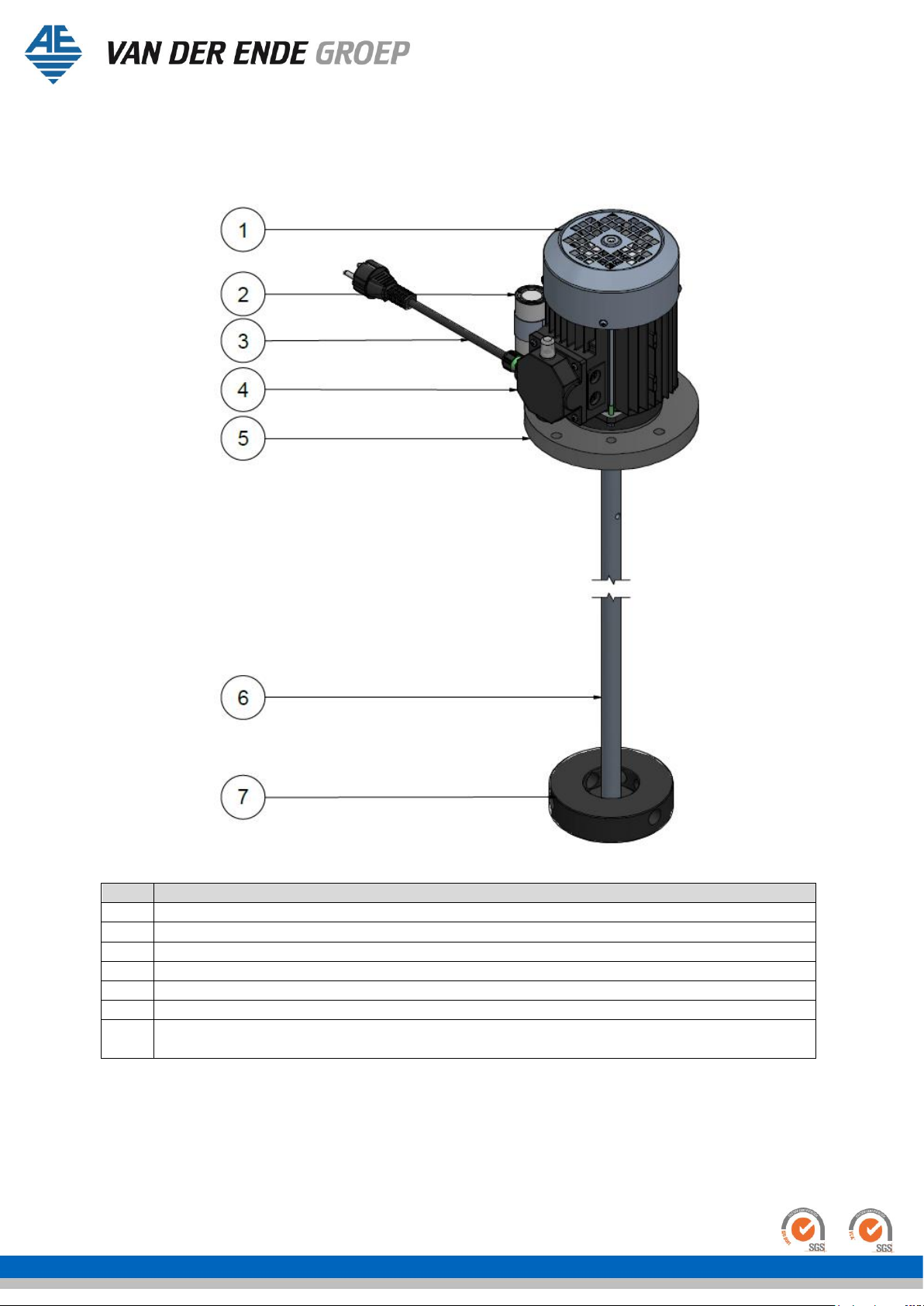

1.1.3 Schematic diagram of the machine............................................................................... 5

1.2 Operation....................................................................................................................... 6

1.3 Use................................................................................................................................ 7

1.4 Users ............................................................................................................................. 7

1.5 Media............................................................................................................................. 7

1.6 Operating environment ................................................................................................... 7

1.7 Guarantee conditions ...................................................................................................... 8

1.8 CE mark ......................................................................................................................... 8

1.9 Residual risks ................................................................................................................. 8

2Description............................................................................................................................. 9

2.1 General .......................................................................................................................... 9

2.2 Operating principle ......................................................................................................... 9

2.3 Transport and storage..................................................................................................... 9

3Safety instructions .................................................................................................................10

4Assembly ..............................................................................................................................11

4.1 General .........................................................................................................................11

4.2 Installation instructions ..................................................................................................11

4.3 Delivery checklist ...........................................................................................................11

4.4 Assembly ......................................................................................................................12

4.5 Installation ....................................................................................................................13

4.6 Connecting / start-up .....................................................................................................13

5Operation/using for the first time............................................................................................14

6Maintenance..........................................................................................................................14

6.1 Regular checks ..............................................................................................................14

7Malfunctions..........................................................................................................................14

8Declaration of Conformity.......................................................................................................15

Notes...........................................................................................................................................16