13mm SPANNER - x1

10mm SPANNER - x1

Assembly & InstallaƟon Guide

EASI-LOAD 3 - SINGLE LADDER KIT

REF: 699-0777-01a

EASI-LOAD 3: SINGLE LADDER KIT

SCALE OF ITEMS WILL VARY TOAID VISUAL IDENTIFICATION, ENSURE ALL ITEMS LISTEDARE PRESENT.

CUSTOMER SERVICE AND TECHNICAL SUPPORT

TEL: 0800 107 0003

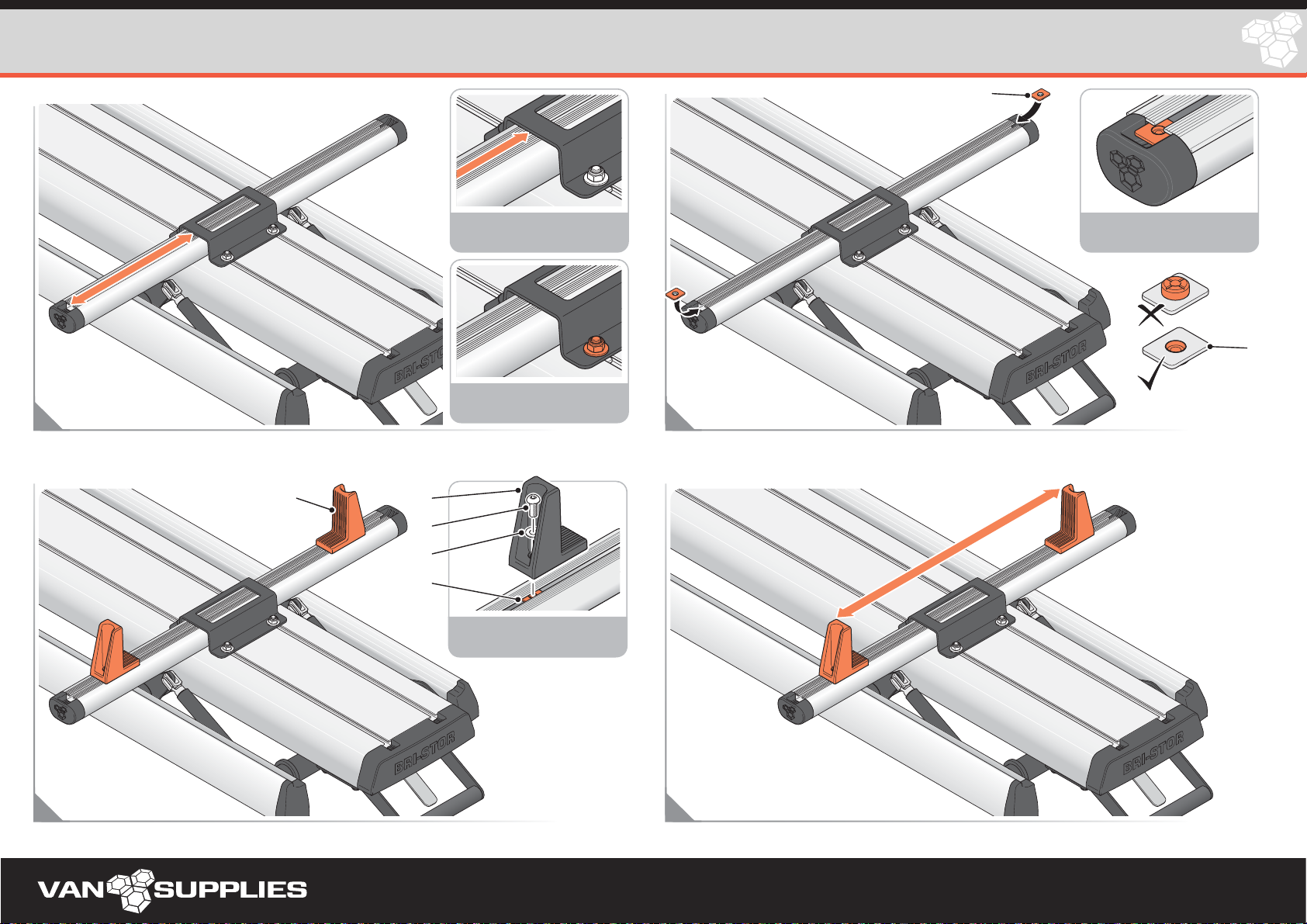

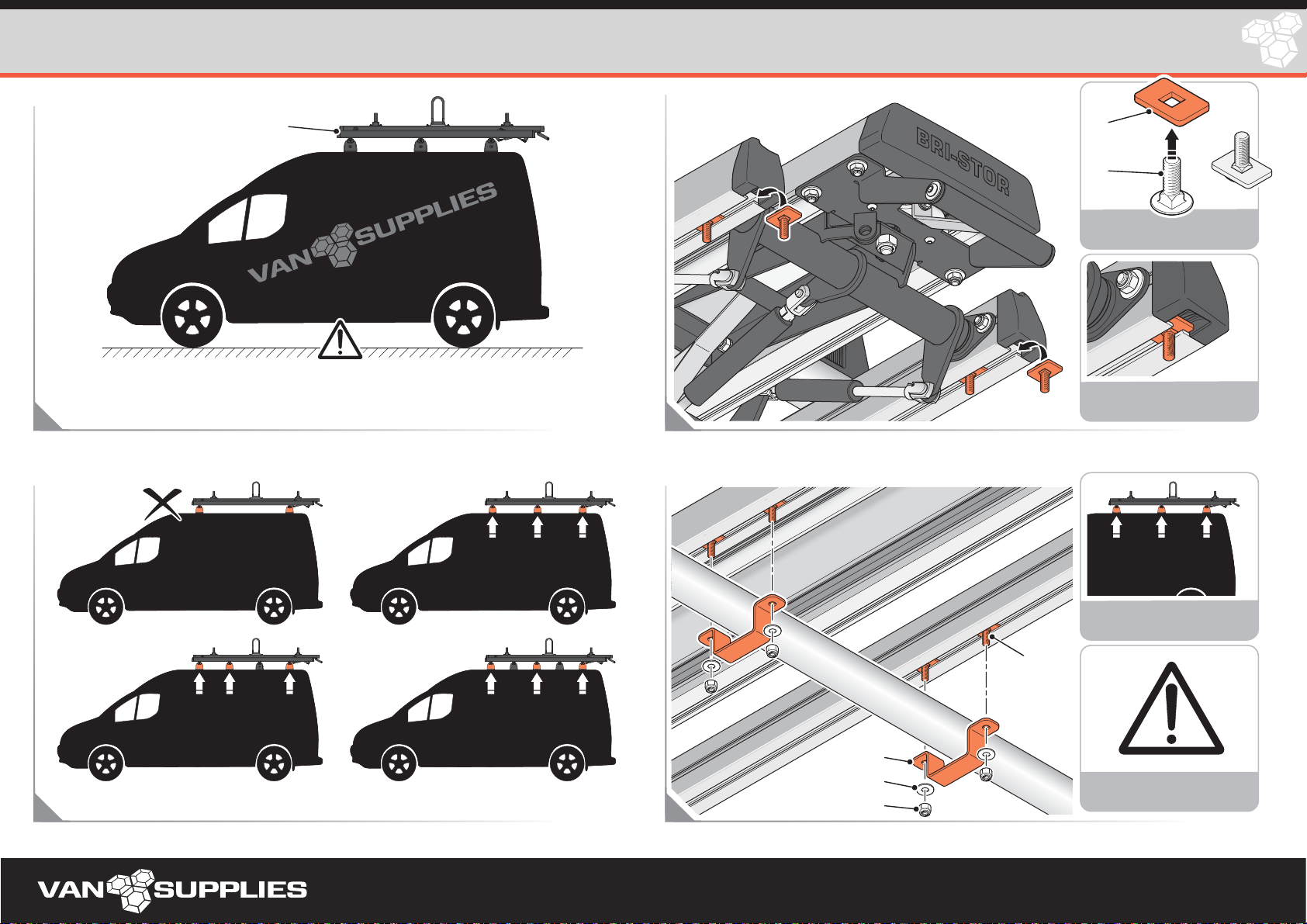

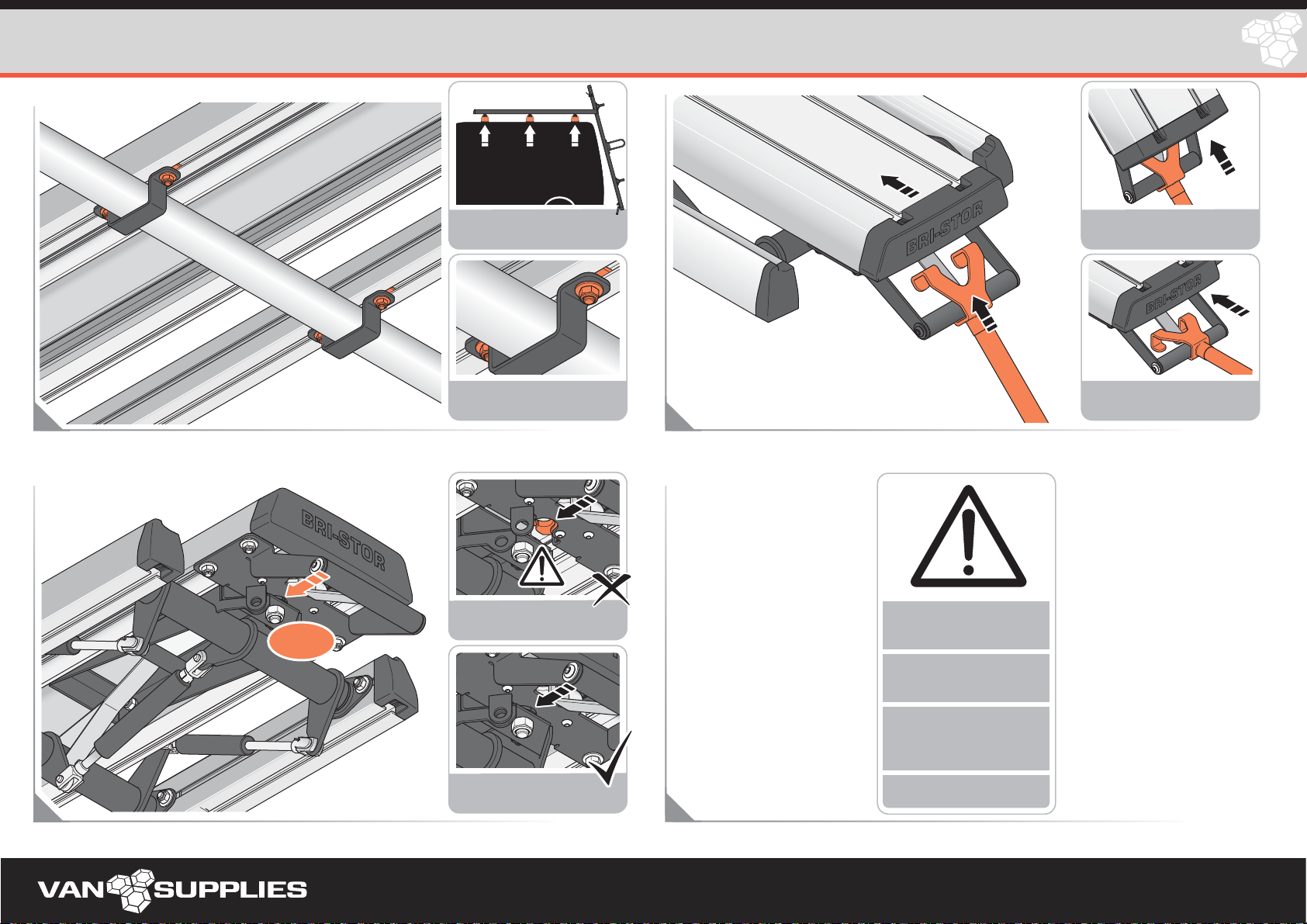

PLEASE READ INSTRUCTIONS FULLY PRIOR TO INSTALLATION OF CROSSBAR KIT

PLEASE ENSURE THAT THE MANUFACTURERS MAXIMUM ROOF LOADING IS NOT EXCEEDED

(Refer to vehicle handbook)

REGULARLY INSPECT EASI-LOAD SYSTEM ENSURINGALL BRACKETS AND FIXINGS ARE SECURE

This instruction is to illustrate the recommended installation method for our Easi-Load 3, any deviation

from this will be the sole responsibility of whoever carries out the installation.

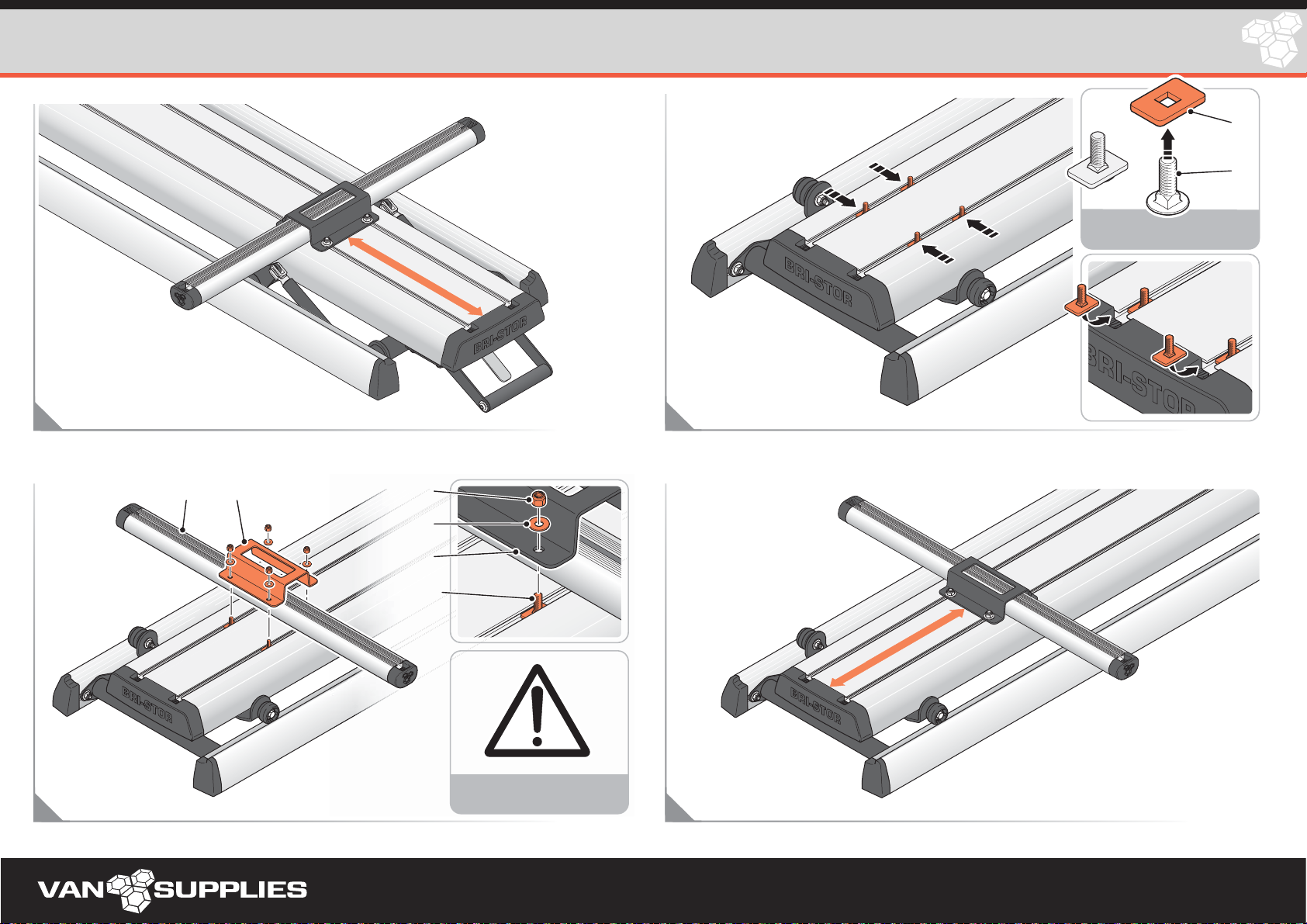

1: EASI-LOAD 3 BASE UNIT - x1

3: 700mm CROSSBAR - x2

4: LADDER STAY - x1

5: LADDER BAR BRACKET - x2

6: LOAD STOP - x4

7: EASI-LOAD MOUNTING BRACKET - x6

10: M6 x 20mm BUTTON HEAD SKT - x4

11: M8 x 20mm COACH BOLT - x12

12: M8 x 25mm COACH BOLT - x12

13: M6 FORM ‘C’ WASHER - x4

14: M8 FORM ‘C’ WASHER - x24

15: M8 NYLOC NUT - x24

8: LOCK NUT - x4

9: SLOT WASHER - x24

2: EASI-LOAD 3 DEPLOYMENT HANDLE - x1

HANDLE WILL BE EITHER 500mm OR 1000mm LONG

TOOLS REQUIRED (Not included within kit)

4mm ALLEN KEY - x1

5mm ALLEN KEY - x1

TAPE MEASURE