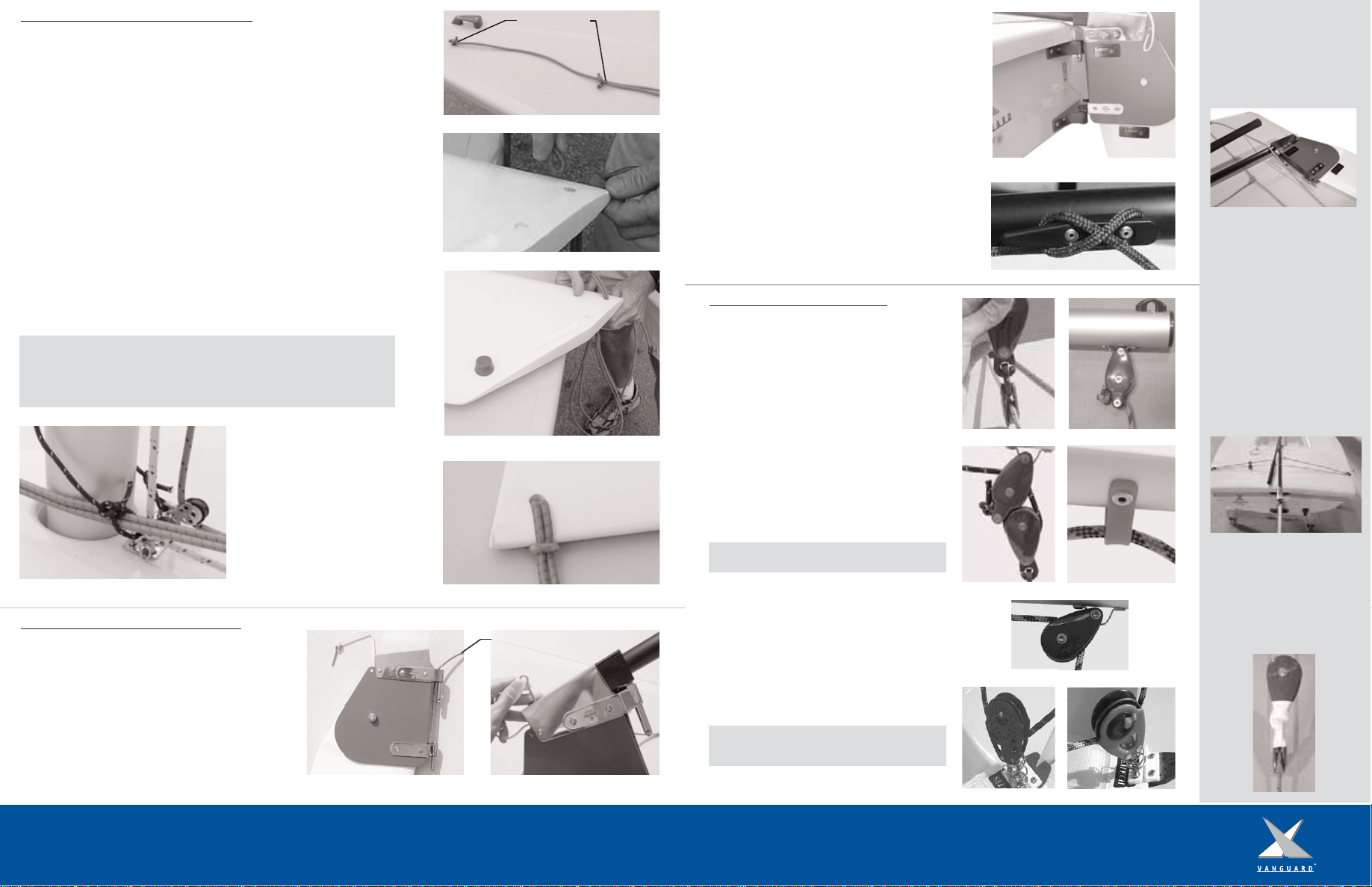

1. From the delivery kit locate the 2, 16mm

forkhead blocks and base. Unscrew the two

screws located by the mast step. Align the

block base over the holes and screw into place

(Figure 9). Attach the forkhead blocks to the

base using the provided pins and rings

(Figure 10).

Here is a list of tools

that we recommend

you have in order to

assemble your new

Laser:

Utility Knife

White Electrical Tape

Phillips Head

Screwdriver

Silicone Sealant

2. Unscrew the set of screws located in front

of the daggerboard well. Align the holes of

the cam cleat and screw into place (Figure 5).

Be sure that the open end of the cleat is

facing towards the cockpit (Figure 6).

3. Locate the ratchet block and spring from

the delivery kit. In the cockpit, at the forward

end of the hiking strap, locate the eyestrap

(Figure 7).

4. Remove the shackle from the bottom of the

ratchet block and place it around the eyestrap

(Figure 7).

5. Place the spring over the eyestrap, and

compress. While the spring is compressed,

attach the block to the shackle with the pin

and ring (Figure 8).

1. In the delivery kit locate the bullseye

fairlead and the clam cleat. Unscrew the two

screws located by the mast step (Figure 3).

Align the bullseye fairlead over the two holes

and screw into place (Figure 4).

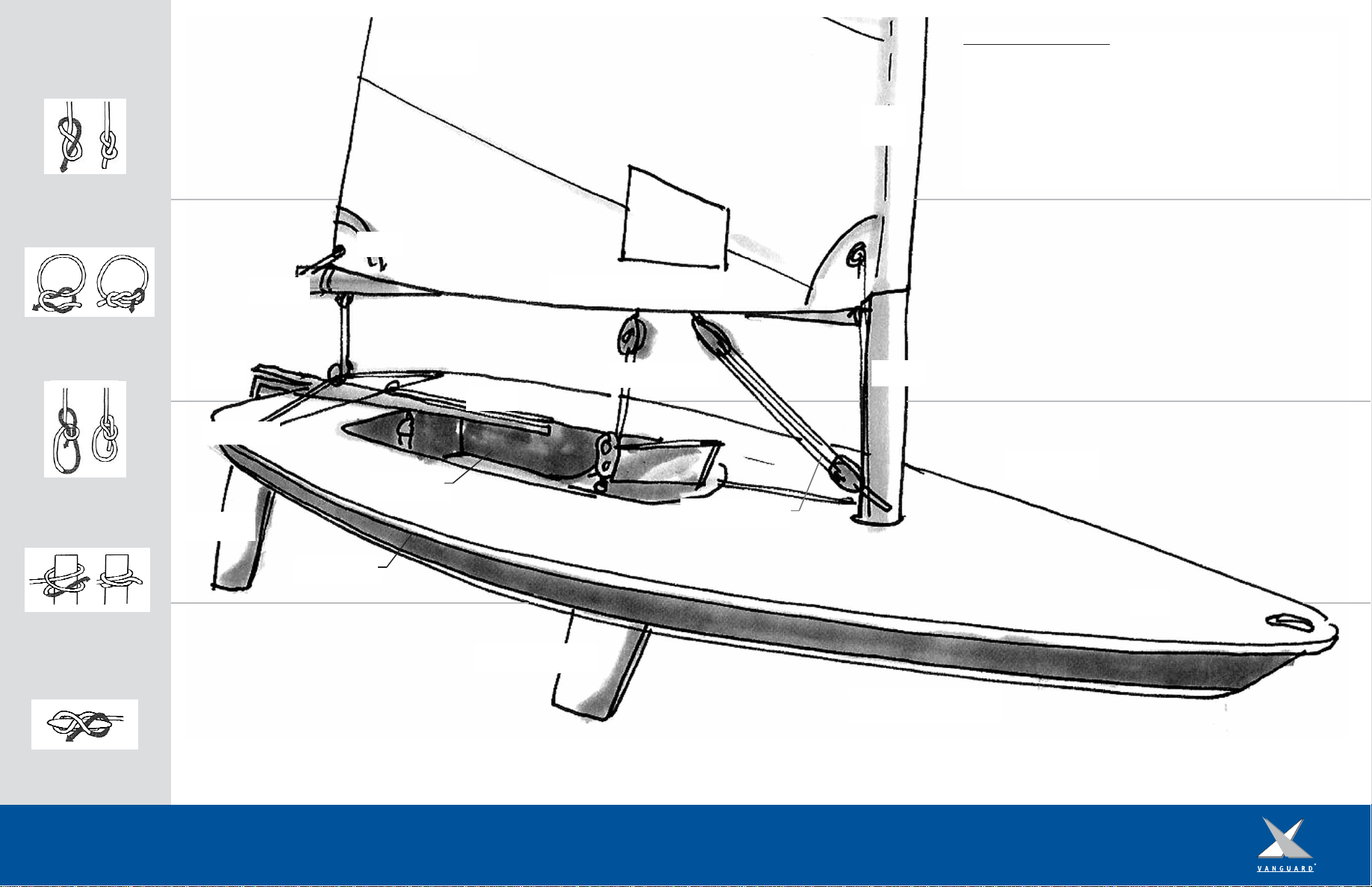

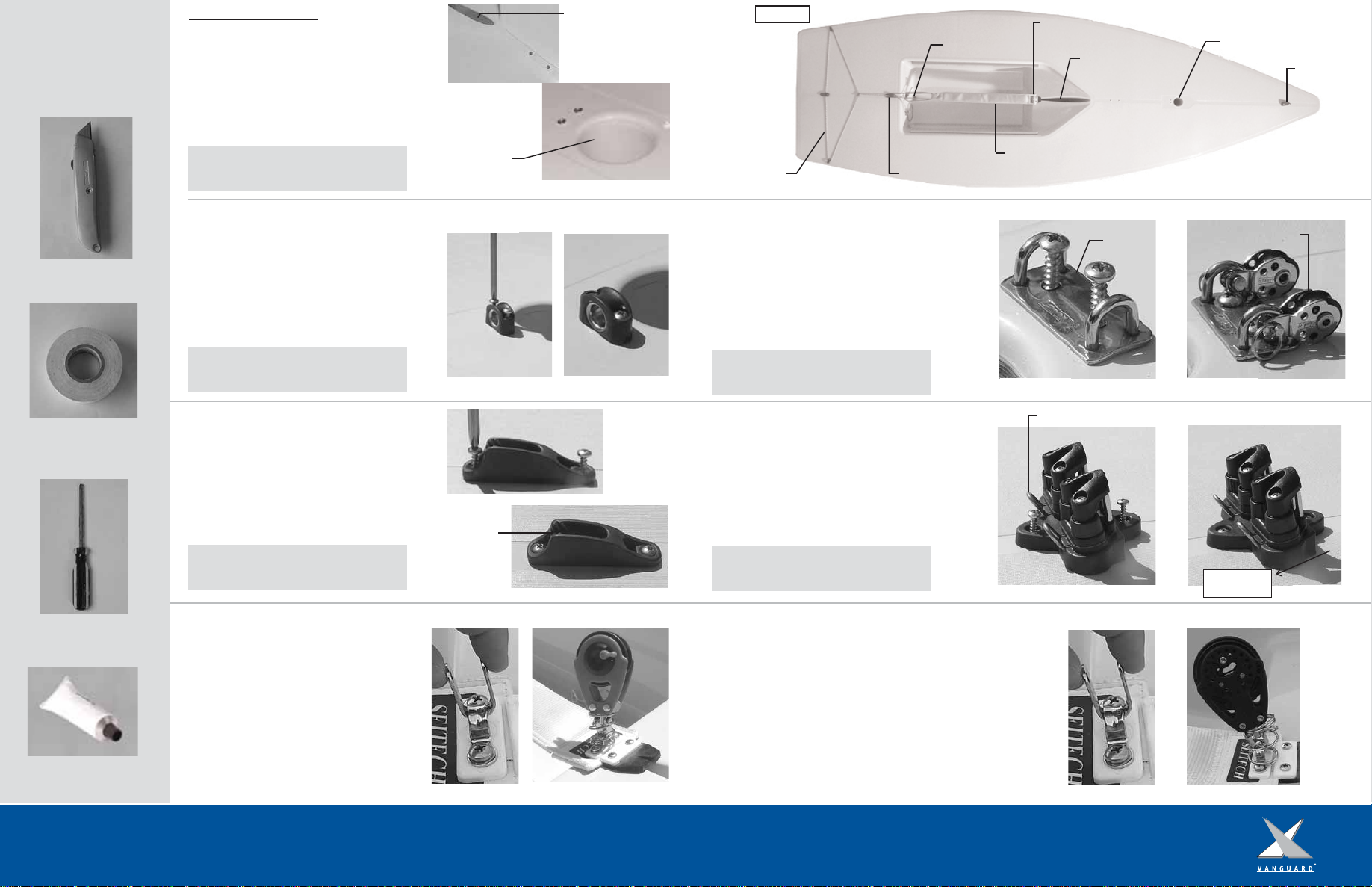

There are a few pieces of hardware that you

will need to install on your new hull before

continuing to rig your Laser. Locate the two

sets of screws that are positioned on the deck

of the boat (Figure A, far right image). One

set of screws will be forward of the

daggerboard well (Figure 1) while the other set

will be aft of the mast step (Figure 2).

Hardware Installation: Laser Standard Models

Tip: Before replacing the screws be sure to dip

them into a silicon based sealant to allow for

a water tight and secure fit.

Hardware Installation: Laser Pro Models

Open end

2. In the delivery kit locate the cleat base

with cleats. Unscrew the two screws located

by the daggerboard well. Align the cleat base

over the two holes and screw into place

(Figure 11). Make sure that the shorter of the

metal fairleads are facing the bow. When

looking at the cleat base from the side, the

cleats should be angled down towards the bow

(Figure 12).

Shorter metal fairleads

Angled down

towards mast

3. Locate the ratchet block and spring from

the delivery kit. In the cockpit, at the forward

end of the hiking strap, locate the eyestrap

(Figure 13).

4. Remove the shackle from the bottom of the

ratchet block and place it around the eyestrap

(Figure 13).

5. Place the spring over the eyestrap, and

compress. While the spring is compressed,

attach the block to the shackle with the pin

and ring (Figure 14).

Bow eye

Mast Step

Hiking Strap

Daggerboard Well

Traveler Clam Cleat

Bailer Plug

Ratchet Block Eyestrap

Figure 1

Figure 2

Figure 3 Figure 4

Figure 5

Figure 6

Figure 8Figure 7

Figure 9 Figure 10

Figure 11 Figure 12

Figure 13 Figure 14

Figure A

Hardware Location:

Reminder: Before replacing the screws be sure

to dip them into a silicon based sealant to

allow for a water tight and secure fit.

Reminder: Before replacing the screws be sure

to dip them into a silicon based sealant to

allow for a water tight and secure fit.

Reminder: Before replacing the screws be sure

to dip them into a silicon based sealant to

allow for a water tight and secure fit.

Reminder: Before replacing the screws be sure

to dip them into a silicon based sealant to

allow for a water tight and secure fit.

Block Base 16 mm Forkhead Blocks

Mast Step

Daggerboard Well