WARNING! Due to the fact that crushed material is handled in the vicinity of the crusher,

there is an increased danger of slipping and tripping in this area.

6.1 Connecting the machine to power supply

The crusher’s electrical equipment can be connected only to the corresponding single-phase, 230 V, 50 Hz

power socket with a protective contact connected to a protection wire. The circuit of the single-phase socket

for connecting the crusher to the power mains must be wired in accordance with the requirements of

regulations and technical standards applicable for the equipment of this type, in particular

ČSN 33 2130, Part 2.3, ČSN 33 2180, Part 6, ČSN 33 2000-4-41, ČSN 332000-5-51 Chapter 512, ČSN

332000-5-54 Chapter 543 and related regulations. The circuit must be at the point of connection protected

against excessive current by a fuse or circuit breaker of a maximum nominal value of 10 A, and due to the

environment and working conditions of the machine, must be equipped with a current protection device of a

maximum nominal tripping differential current In = 30 mA! This will provide the machine with an enhanced

protection against electric shock. If it is necessary to use an extension power cord to connect the crusher to

power mains, the extension power cord must be fitted with a plug and a socket of the same type and of the

same nominal current rating and the same nominal voltage rating and designed for the use in external

environment. The cross-section of the power cord’s wires must not be smaller than 1.5 mm2and 2.5 mm2for

extension power cords up to 25 m and 50 m long, respectively.

WARNING! Extension power cords longer than 25 m should be used only in exceptional

circumstances, and an increased care should be taken to protect them against mechanical

damage. Using extension cables longer that 50 m is not permitted, as reliable functioning of

the protection against electrical shock cannot be guaranteed.

Extension power cords must be laid in accordance with the requirements of ČSN 34 0350 Article 3509 and

Article 3510, guaranteeing their adequate protection against mechanical damage and making sure that they

are not in the way in the area through which they are running. As a protection against mechanical damage,

use mainly protection by correct positioning, i.e. run the power cord through places where it will not be

exposed to any danger of mechanical damage.

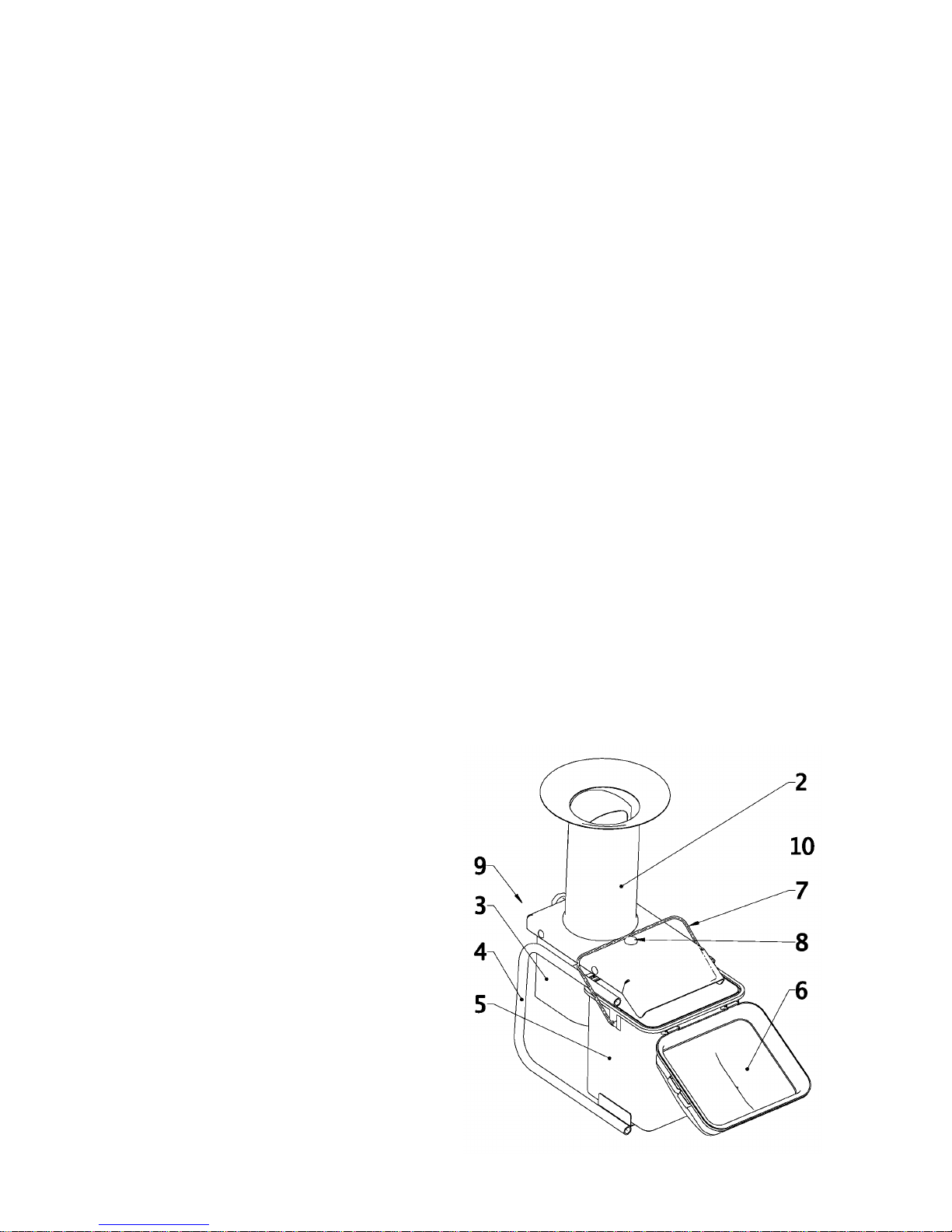

7 Putting the machine into operation

Before putting the machine into operation, the operator must evidently familiarise him/herself with basic

information about the machine, its functions, safety instructions as defined in Chapter 4 of this User’s Guide

and with the principles of maintenance specified in Chapter 9 of this User’s Guide. Before first starting the

machine, check whether all its parts are adequately mechanically attached and make sure that there are no

foreign objects in the work compartment. If no defect has been found, proceed to put the machine into

operation according to the following instructions.

Set the machine’s electrical drive switch into the position I “ON”.

Please note: You don’t have to check rotating direction of the electromotor. The electromotor is

factory-wired to drive the work mechanism in the correct direction.

After the crusher’s electromotor has reached full operating speed, you can start loading material into the

crusher.

Warning: When the crusher has stopped due to overloading, it is prohibited to take the

contents out of the work compartment by hand and put hands into the interior, unless the

machine is in standstill and its switched off state secured by turning off the switch and

pulling the power cord plug out of the power supply socket!

Warning: When working with the crusher, operators must wear personal protection aids: ear

protectors to protect their hearing organs.

WARNING!: Frequent overloading of the electromotor might lead to the generation of excessive

heat and damage the motor.