MODE D'EMPLOI

3 87-900-847-01 (B)

INDICATIONS GENERALES

Cet appareillage a été conçu en vue d'une utilisation

professionnelle. Il est conseillé à l'utilisateur de lire

attentivement cette notice d'instructions ainsi que toute

autre indication supplémentaire fournie par Varian,

avant l'utilisation de l'appareil. Varian décline par

conséquent toute responsabilité en cas d'inobservation

totale ou partielle des instructions données, d'utilisation

incorrecte de la part d'un personnel non formé,

d'opérations non autorisées ou d'un emploi contraire

aux réglementations nationales spécifiques.

Les paragraphes suivants donnent toutes les

indications nécessaires à garantir la sécurité de

l'opérateur pendant l'utilisation de l'appareillage. Des

renseignements plus détaillés se trouvent dans

l'appendice "Technical Information".

Cette notice utilise les signes conventionnels

suivants:

!

Les messages de danger attirent l'attention de

l'opérateur sur une procédure ou une manoeuvre

spéciale qui, si elle n'est pas effectuée correctement,

risque de provoquer de graves lésions.

ATTENTION

Les message d'attention apparaissent avant certaines

procédures qui, si elles ne sont pas observées,

pourraient endommager sérieusement l'appareillage.

NOTE

Les notes contiennent des renseignements importants,

isolés du texte.

EMMAGASINAGE

Pendant le transport et l'emmagasinage des

contrôleurs, il faudra veiller à respecter les conditions

environnementales suivantes:

•Température: de - 20 °C à + 70 °C

•Humidité relative: 0 - 95% (non condensante).

PREPARATION POUR L'INSTALLATION

Le dispositif est fourni dans un emballage de protection

spécial; si l'on constate des marques de dommages

pouvant s'être produits pendant le transport, contacter

aussitôt le bureau de vente local. Pendant l'opération

d'ouverture de l'emballage du hand held terminal, ,

veiller tout particulièrement à ne pas laisser tomber le

contrôleur et à ne lui faire subir aucun choc. Ne pas

jeter l'emballage dans la nature. Le matériel est

entièrement recyclable et il est conforme aux directives

CEE 83/399 en matière de protection de

l'environnement.

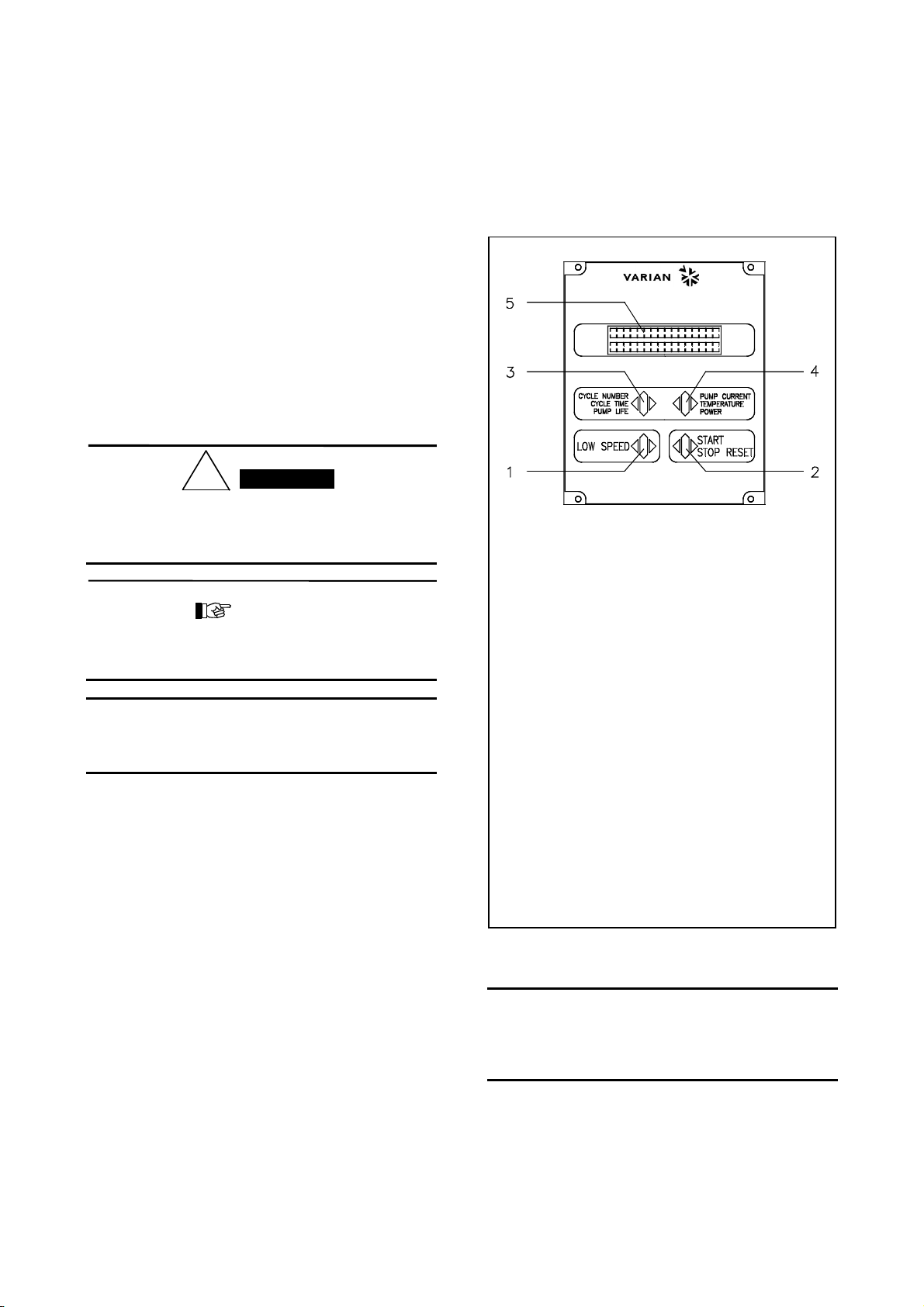

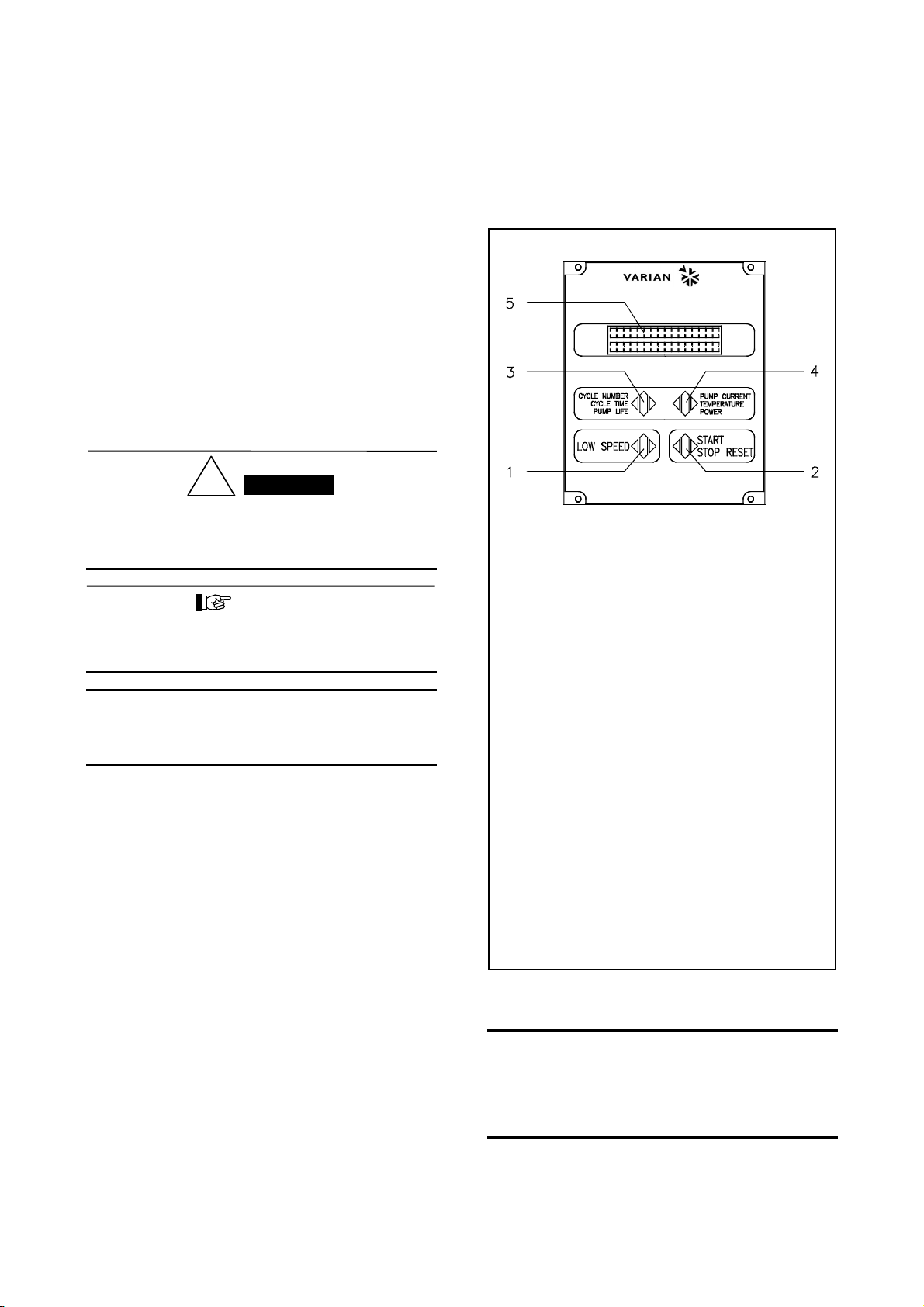

Commandes, indicateurs et connecteurs du

hand held terminal

On présente ci-dessous le tableau de commande du

hand held terminal. Pour de plus amples détails, se

reporter à la section "Technical Information".

1. Interrupteur de sélection du mode LOW SPEED. Il n'est

actif que lorsque le mode de commande est sélectionné

depuis le tableau frontal. En le pressant une fois, la

pompe tourne à 2/3 environ de la vitesse nominale. En

le pressant une deuxième fois, on désactive le mode

LOW SPEED.

2. Interrupteur envoyant les commandes de START,

STOP ou RESET. Il n'est actif que lorsque le mode de

commande est sélectionné depuis le tableau frontal.

Une première pression de l'interrupteur active la phase

de mise en marche; une deuxième pression provoque

l'arrêt de la pompe. Si la pompe s'est arrêtée

automatiquement à cause d'une panne, il faut presser

cet interrupteur une première fois pour effectuer la mise

à zéro du dispositif et une deuxième fois pour remettre

la pompe en marche.

3. Interrupteur rappelant sur l'afficheur les paramètres de

cycle number, cycle time et pump life.

4. Interrupteur rappelant sur l'afficheur les paramètres de

pump current, pump temperature, pump power et

rotational speed. Il est toujours actif, indépendamment

du mode de fonctionnement choisi. En pressant

simultanément les interrupteurs 3 et 4 pendant 2

secondes au moins, on active un programme avec

lequel il est possible de programmer certains

paramètres opérat-ionnels.

5. Ecran alphanumérique à cristaux liquides: matrice de

points, 2 lignes x 16 caractères.

Tableau avant du Hand Held Terminal

NOTE

Les fonctions de LOW SPEED et START/STOP

RESET ne sont actives que lorsque le mode de

commande est séléctionné depuis le tableau frontal (se

reporter à la section "Technical Information").

DANGER!