3

The bowl must be mounted when the mixer is

started!

The machine must be monitored while it is in

operation

A. Turn the rotary knobs to the locking symbol .

B. Tilt backwards the upper part of the mixer.

C. Place a tool in the bayonet shaft and turn it counter-clockwise

to lock it in position .

D. Place the bowl in the mixer (1), turn it to be xed in the lock-

ing bolts (2) and turn the handle (3) .

Fill the ingredients in the bowl.

F. Tilt the upper part of the mixer, including tool, down.

Start the mixer by turning the rotary knobs away from the

locking symbol and past 1. To avoid splashing and dust from

our, it is recommended to increase the speed gradually

until the required speed is obtained , (see for

recommended working speeds).

H. Stop the mixer by turning the rotary knobs back to neutral

position .

I. The upper part of the mixer can only be tilted backwards

when the rotary knobs is turned to the locking symbol

.

The working capacity of the mixer depends of:

• The tool used.

• Sort and quantity of the raw materials.

• The optimum speed for a good result.

Too big quantities will always reduce the quality

of the product and the life of the mixer. Overload-

ing can also result in sudden stops.

If the mixer is moving e.g. kneading dough, this is not due to er-

rors or overloading.

In case of overloading the electronic variator will reduce the current

to the motor and stop it.

In case of stop due to overloading, turn the

rotary button back to neutral position, and

the mixer can be started again.

If the motor stops after long time of operation, and cannot be

started immediately after, the temperature sensor of the motor has

switched o the current, and the mixer needs to cool down before

it can be re-started. This protects the motor from overheating.

The mixer contains two thermal cut-outs, which automatically

reconnect in case of previous disconnection by the temperature

sensor.

After use:

• Remove bowl and tools.

• Wash the bowl and the tools in hot water and detergent /

degreaser / disinfectant. Rinse with pure water and dry.

Do not spray water on the mixer

Tools and bowl can be cleaned in dishwasher.

• Wipe the housing of the planetary gear, the bayonet shaft

and the bowl screen. Use a damp sponge and a detergent

/ disinfectant. Rinse the parts with sponge and pure water.

• Check that the various parts have been cleaned thoroughly.

• Do not use abrasive detergents, which could scratch the

surface.

• Use detergents suited for use on aluminium and plastic

(polycarbonate).

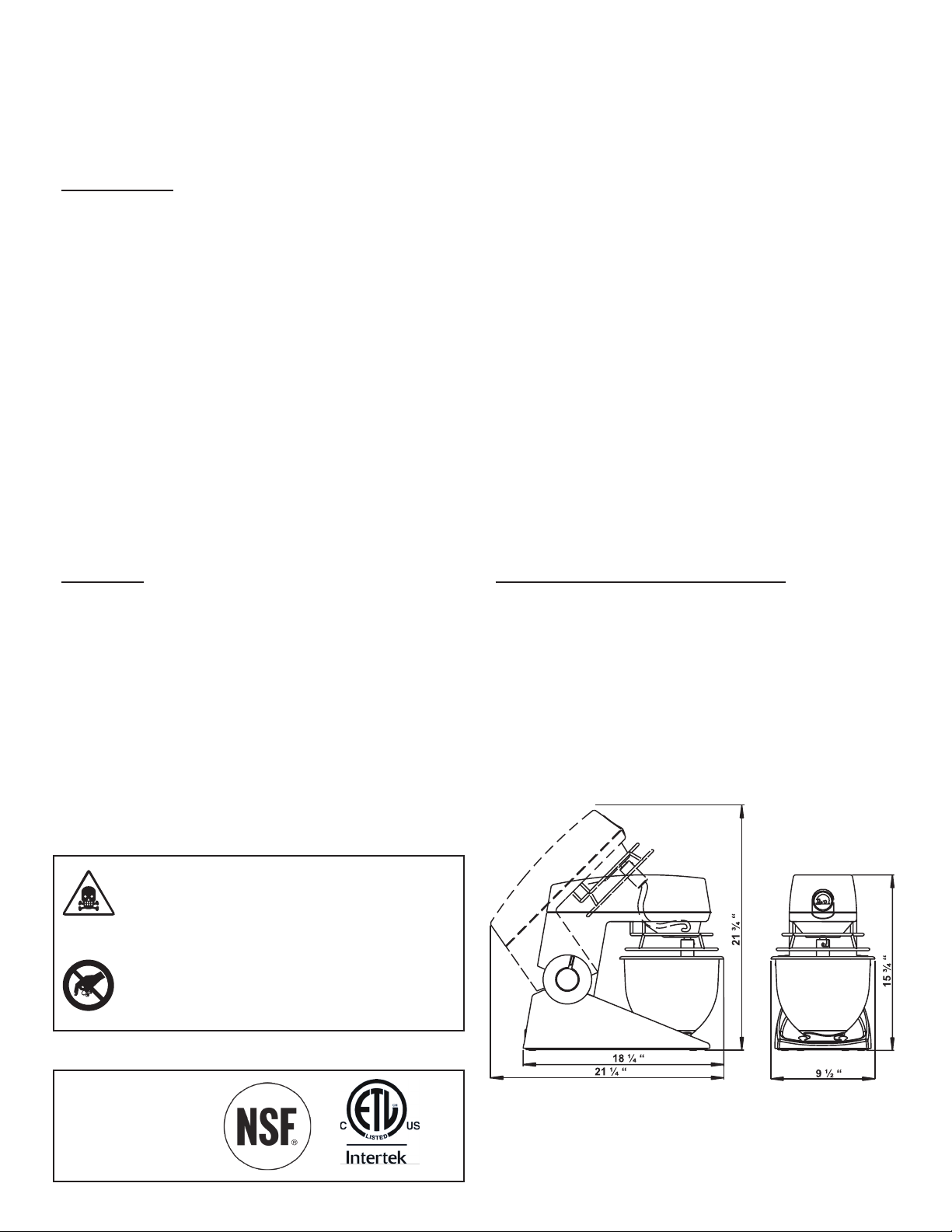

A: Locking symbol B: Neutral position C: Speeds

Fig. 4 Mounting of tool in the bayonet shaft.

Fig.3 The three positions of the rotary knobs.

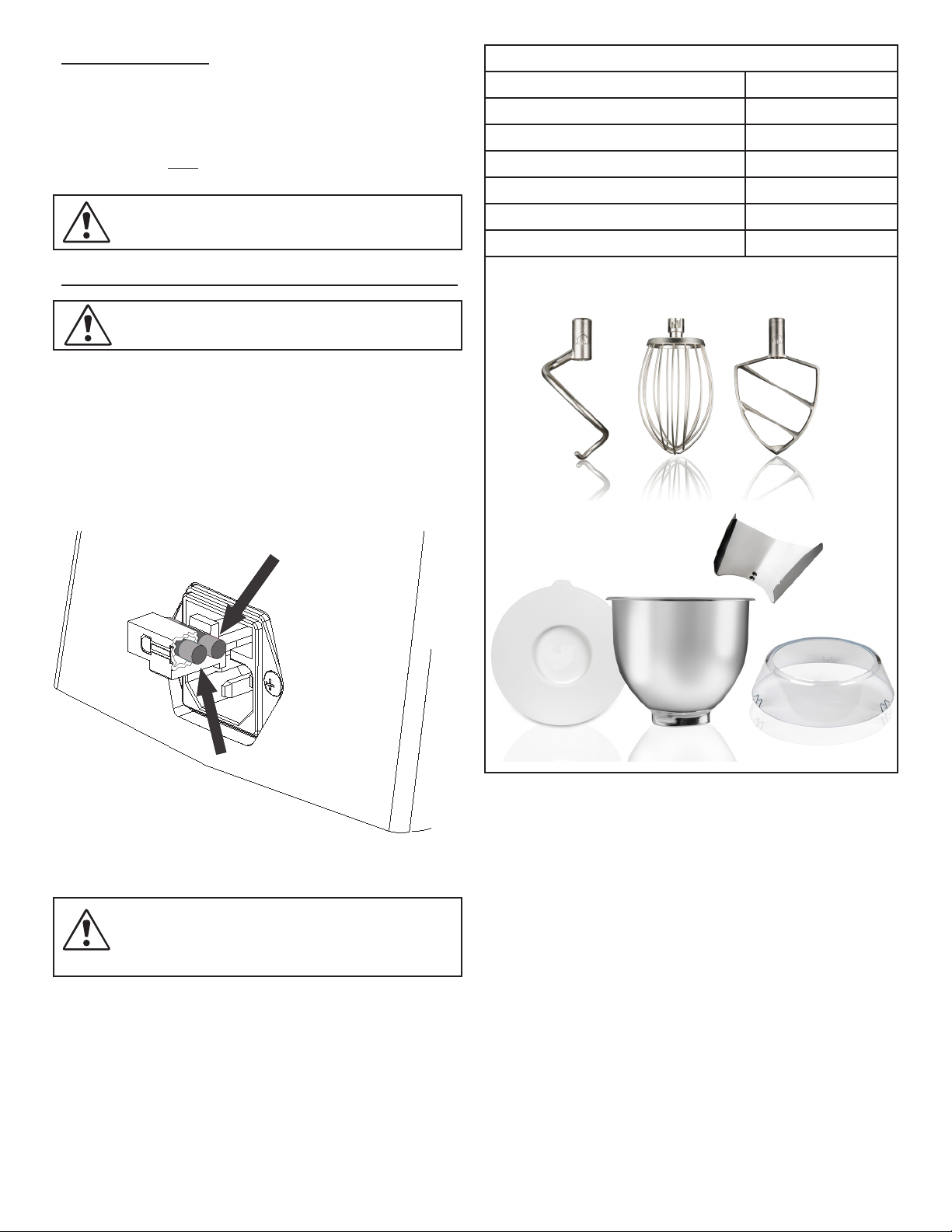

Raw material Approx. max.

quantity

Bread dough, 60% Lbs 5

Mashed potatoes Lbs 4

Whipped cream Qt 1

Layer cake Lbs 6

Cake donuts Lbs 6

Locking bolts

3

locking bolts and turn the locking arm anticlockwise.

Close the ma-

chine by press-

ing down on the

top of the head

section.

click when the

machine has

closed properly