-4 -

IUM

SAFETY WARNINGS

PRODUCTS LAYOUT

2 SAFETY WARNINGS

2.1 Products Operation

During operation, outer surfaces of gearboxes and variators may warm up because of in motion parts and also by external

environmental conditions.

Everything referred to transport, stocking, assembling, setting up, starting and maintenance must be performed by trained

personnel and that follows this manual within specific national / regional regulations about safety and prevention of

accidents.

2.2 Prevalent Use

Gearboxes and variators referred to in this manual are destined to operate industrial applications and they correspond to

standards and regulations where applicable.

Performances and technical data are available in the unit’s nameplate and from the related documentation.

2.3 Transport

Carefully check the state of the goods at their receipt and immediately notify the possible damages to the carrier.

2.4 Long-Term Storage

Stocked units must be kept in dry warehouse and dust free.

For storage longer than 3 months, apply antioxidants on the shafts and machined surfaces paying special attention to

oilseal lips.

Storages longer than one year reduce bearing grease lifetime.

2.5 Environmental Management

In conformity with Environmental Certification ISO14001, we recommend the following to dispose of

• scrapped gearbox components: to deliver to authorised centres for metal object collection:

• drained oils and lubricants: to deliver to Exhausted Oil Centres;

• product accompanying packages (pallets, carton boxes, paper, plastic, etc.): to deliver into regeneration / recycling

circuits as far as possible, by delivering separate waste classes to authorised companies.

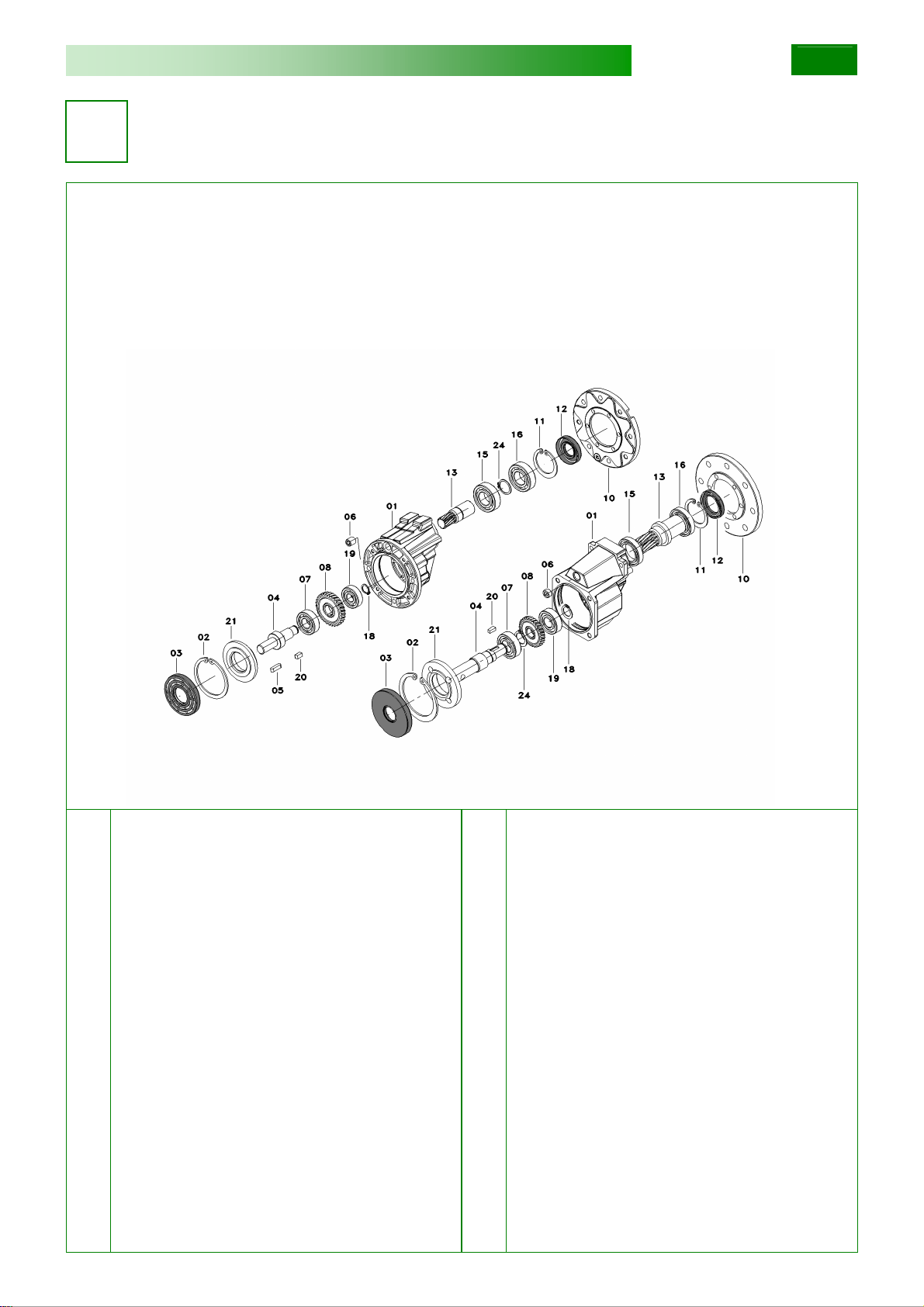

3 PRODUCTS LAYOUT

The following layouts supply a generic help in finding out the most significant parts of the products.

Various design executions of sizes, assembling versions, number of stages actually origin a variety of solutions and

therefore, we recommend to refer to the appropriate catalogue.

http://www.wentellagers.nl