4

3 TECHNICAL DATA

·Die-cast aluminium body and rim

·Steel gears, roller bearings

·Rim mounted on bearing

·Drive shaft mounted on double ball bea rings

·Asynchronous 4 pole motor 1.400 rpm

·Class B isolation

·Thermal protection on motor: 160°C.

·Easy limit-switch adjustment

·6 mt. maximum shutter height

·Alimentation electric cable: 4x1 mm2

·Operating temperature: -20°C. ÷ 85°C.

·Fittings for electrobrake mounting.

4 INSTALLATION INTRUCTIONS

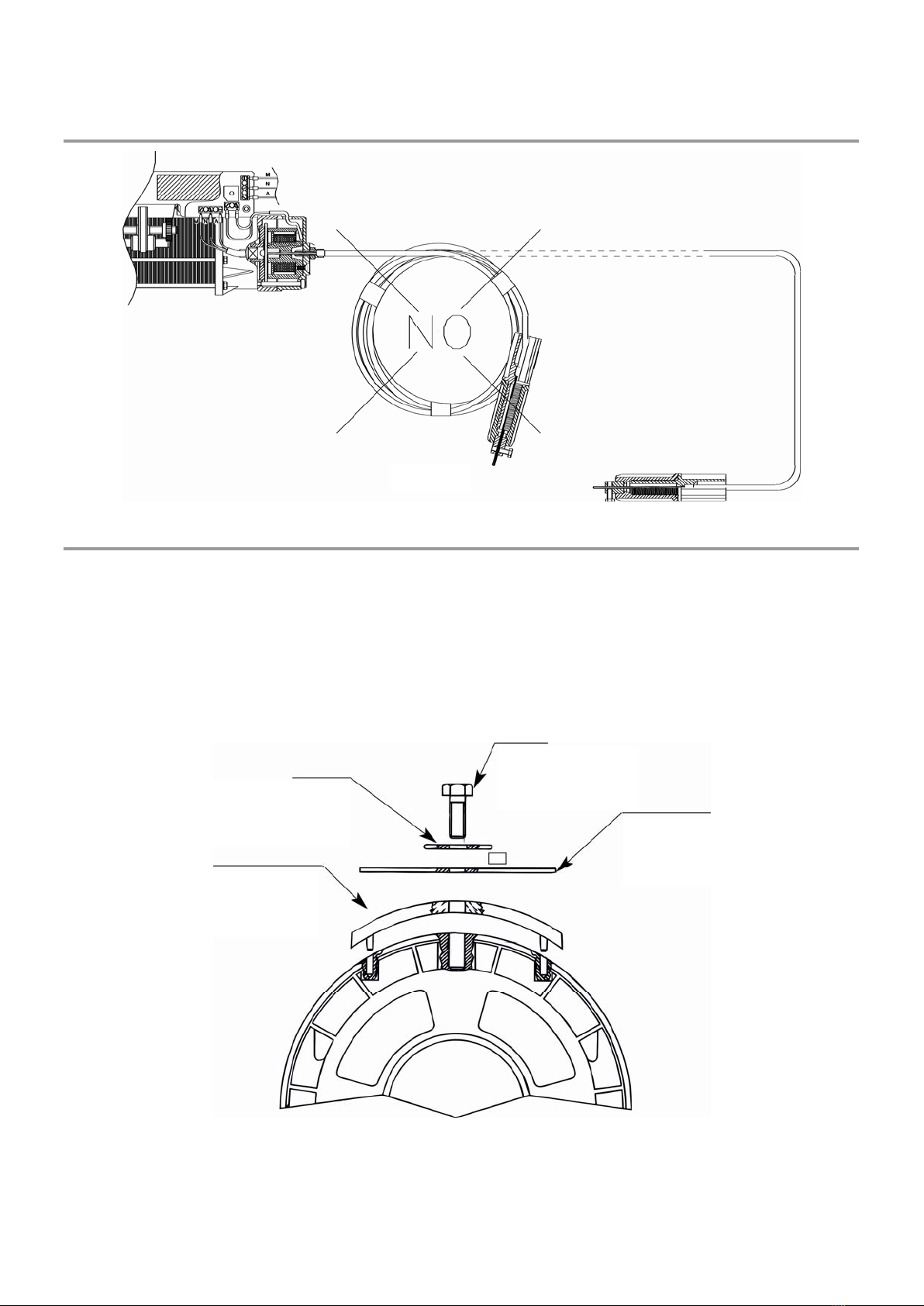

1) Drill a 10 mm diameter hole 5 cm from the centre of the shutter’s shaft (see FIG. 1);

2) Remove the M10 screws from the gear of the gearmotor.

3) Remove the two semi-gears by unscrewing the two M8 screws (using a 6 mm hexagonal wrench);

4) Carefully remove, avoiding any folding, the black plastic roller carrier band;

5) Separate the two elements of the gearmotor (upper and lower body) acting on the four M8 screws (using a 6 mm

hexagonal wrench);

6) Should the shutter shaft be less than 60 mm long, use the dedicated reducing sockets positioning them using

the previously drilled 10 mm diameter hole as a reference (point 1);

7) Join the upper and lower bodies using the four M8 screws removed before;

8) Tighten the M10 screw without hexagon nut using a 17 mm wrench and ensure it enters the shutter shaft via the

10 mm hole (previously drilled);

9) Install the roller band in its appropriate housing;

10) Apply the semi-gears, holding them with the two M8 screws;

11) Tighten the M10 screw with nut so as to block the gearmotor on the shaftand tighten said nut;

12) Place the last canvas of the shutter on the shaft and drill a 12 mm diameter hole at the same location as the

M10 threaded hole on the gear;

13) Tighten by hand the gear by 1-1½ turns by bringing the grip towards microswitch 1 (down) fig. 1 (it must turn

easily);

14) Lock the shutter to the gearmotor using the M10 screw with washer (using a 17 mm wrench);

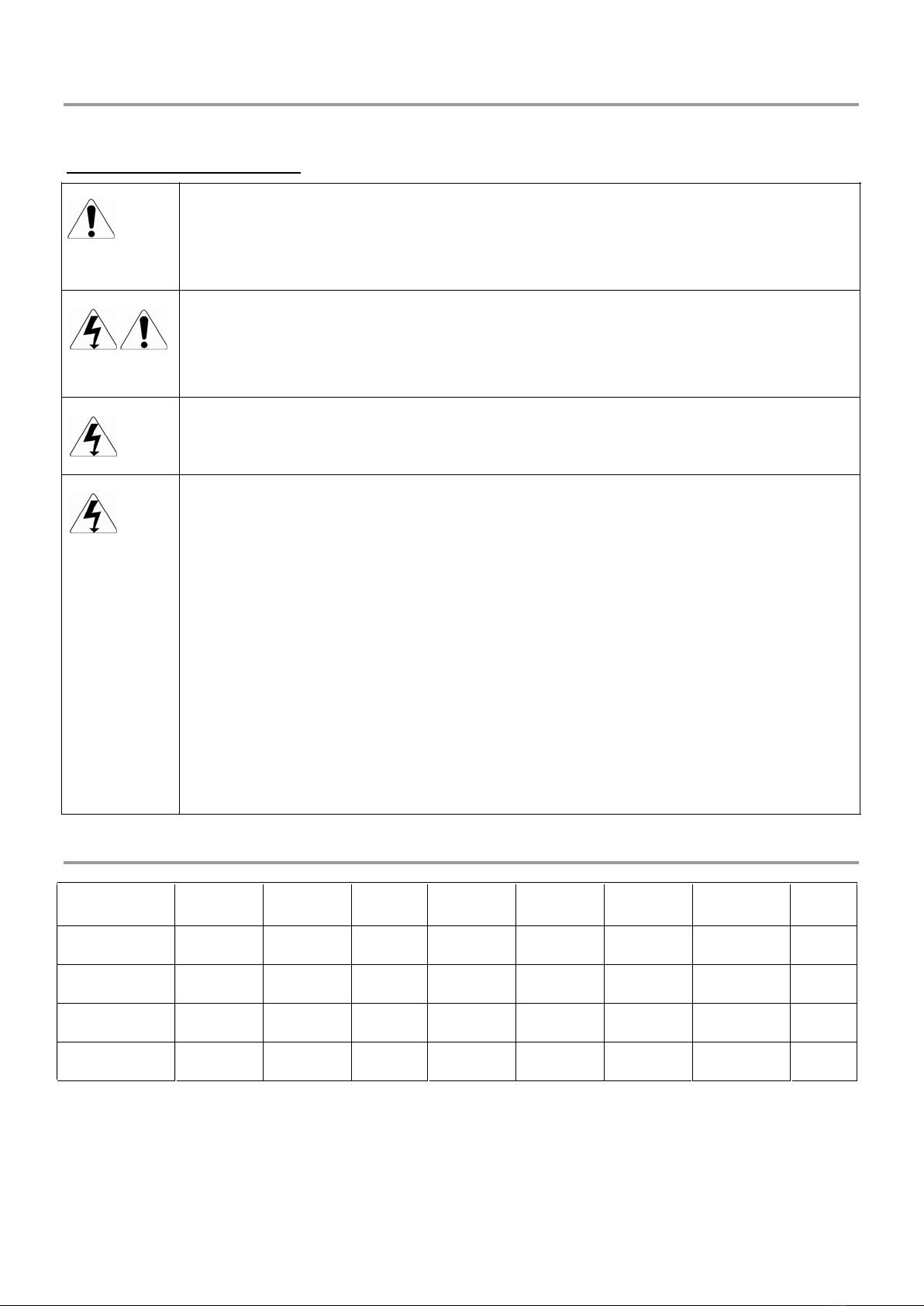

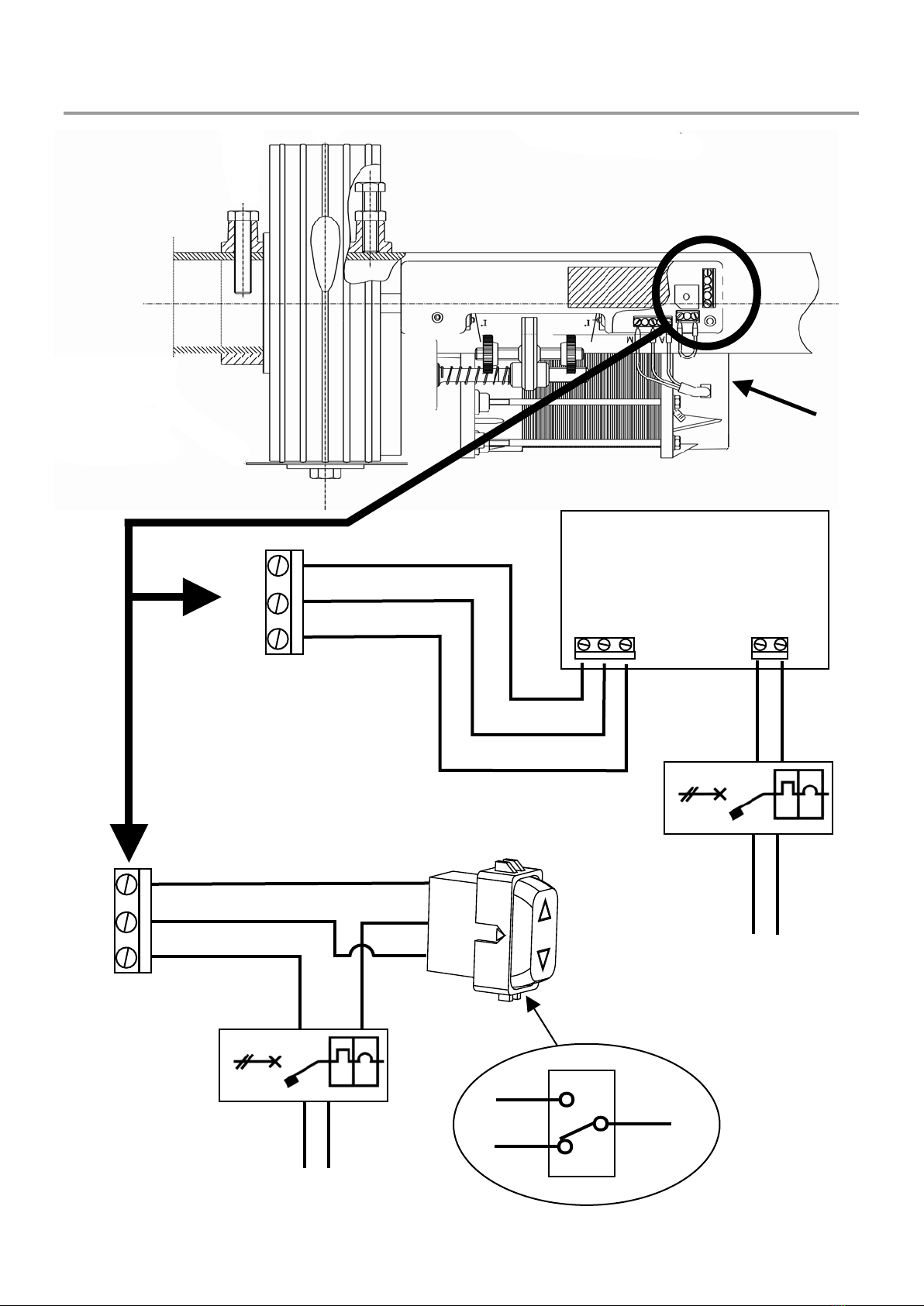

15) Make the electrical connections described in FIG. 2 passing the 4x1 mm2cable inside the shutter shaft avoiding

any contact with the rotating pars;

16) After having installed the mechanical parts and electrical contacts, proceed to regulate the end of travel;

17) Turn the end of travel grip by hand until you hear the click of the microswitch’s trigger (down regulation

completed);

18) Turn the other grip towards microswitch 2 (up). Switch on current to the gearmotor via the key selector or

button to ensure that when rising the shutter stops at the correct point to regulate the position, adjust the grip, using

solely and exclusively the electric commands taking all precautions to avoid manual lifting.

19) Should the shutter need to be installed contrary to the description in FIG. 1, the steps described above should

be carried out to the contrary as microswitch 2 will stop the descent and microswitch 1 will stop the opening.