2

Contents

1. Safety Instruction ....................................................................................................................................... 4

1.1 Symbol Function ........................................................................................................................ 4

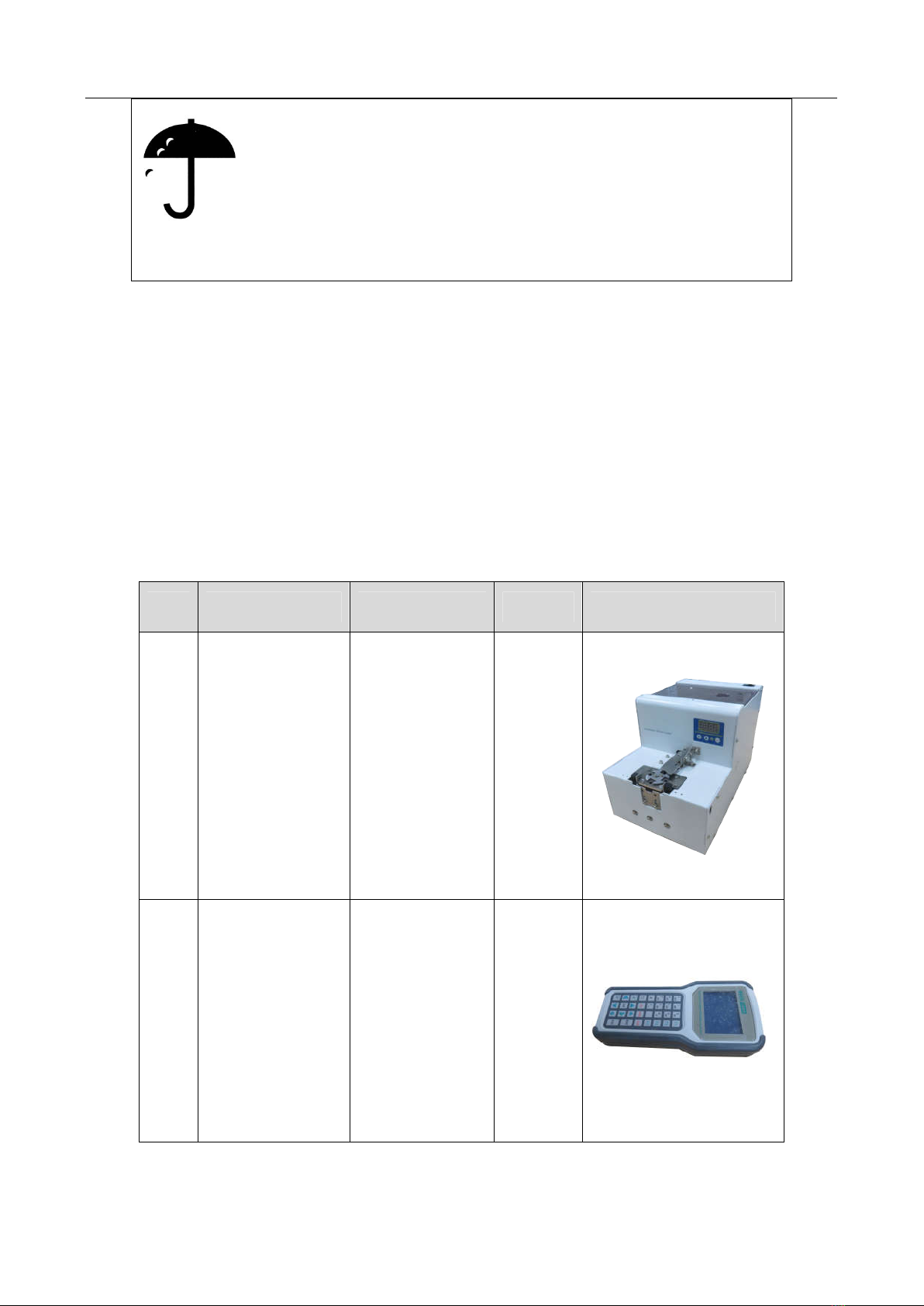

1.2 Unpacking & Inspection ............................................................................................................ 6

2. Introduction ............................................................................................................................................... 8

2.1 Specifications ............................................................................................................................. 9

2.2 Parts Description ...................................................................................................................... 10

2.3 Dimension .................................................................................................................................11

3. Connection & Use .................................................................................................................................... 12

3.1 Connection ............................................................................................................................... 12

3.2 I/O Socket Instruction .............................................................................................................. 13

3.2.1 Circuit Instruction of I/O Socket ...................................................................................... 13

3.2.2 4-pin Socket Instruction ................................................................................................... 13

3.2.3 5-pin Socket instruction ................................................................................................... 14

3.2.4 6-pin Socket Instruction ................................................................................................... 14

3.2.5 8-pin Socket Instruction ................................................................................................... 15

3.3 Instruction about DB9 Socket .................................................................................................. 16

3.3.1 Pins Instruction of DB9 Socket 1 ..................................................................................... 16

3.3.2 Pins Instruction of DB9 Socket 2 ..................................................................................... 16

3.4 Input & Output Instruction ...................................................................................................... 17

3.4.1 I/O Ports Description ....................................................................................................... 18

3.4.2 I/O Function Instruction ................................................................................................... 20

4. Commissioning ........................................................................................................................................ 22

4.1 Debug Steps ............................................................................................................................. 22

4.1.1 Security Check before Operation ..................................................................................... 22

4.1.2 Operation of First Time .................................................................................................... 23

4.1.3 Set Screwing Position ...................................................................................................... 23

4.2 Interrupt and Continue ............................................................................................................. 26

5. Operation Panel ....................................................................................................................................... 28

5.1 Introduction .............................................................................................................................. 28

5.2 Main Window (with teach pendant) ......................................................................................... 29

5.3 Main Window (disconnect teach pendant cord) ....................................................................... 29

5.3.1 Loop Window .................................................................................................................. 30

5.3.2 S-point Window ............................................................................................................... 31

6. Troubleshooting & Maintenance ............................................................................................................. 32