ISSUED: 03-19-03 SHEET #: 017-9011-4 06-13-07

Visit the Peerless Web Site at www.peerlessmounts.com For customer service call 1-800-729-0307 or 708-865-8870.

4 of 6

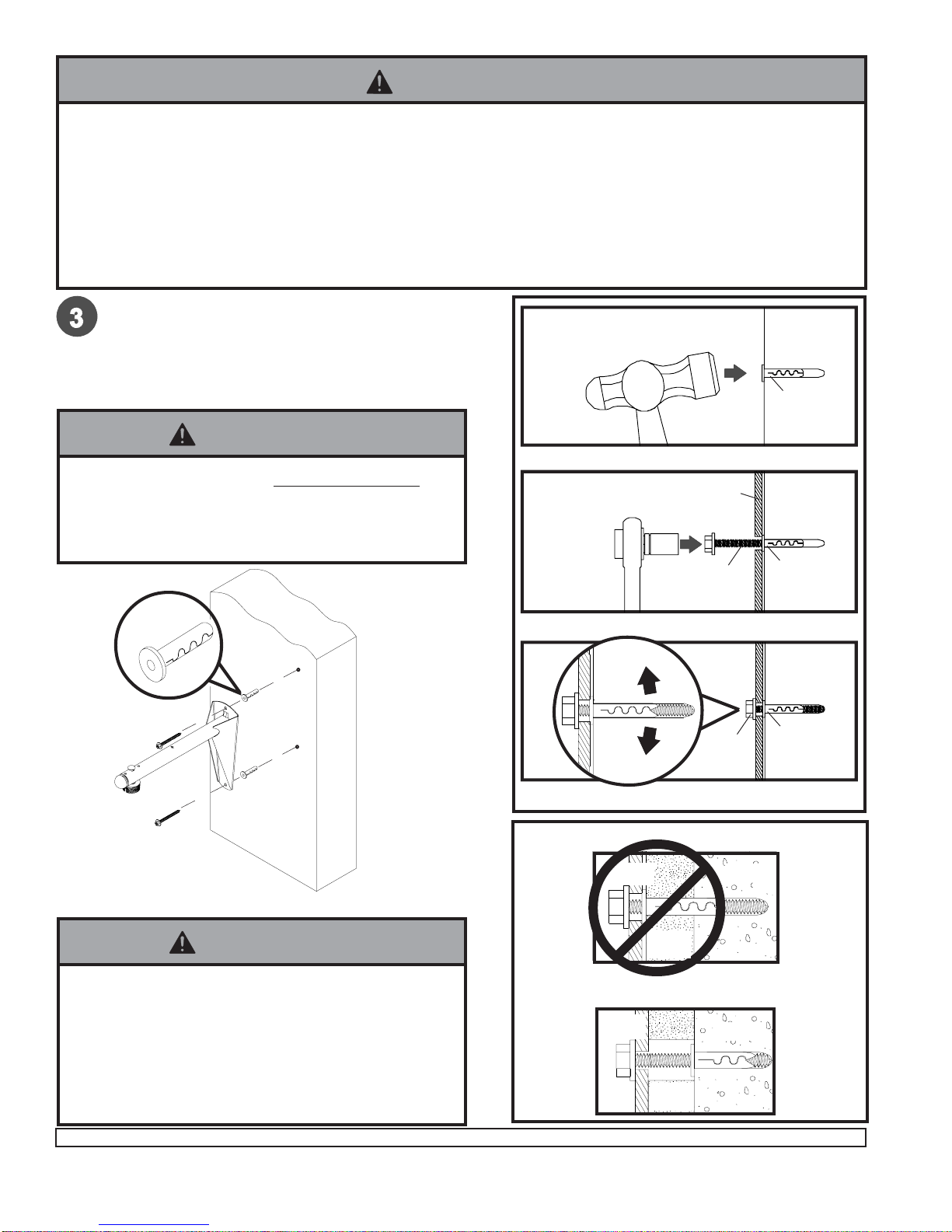

Installation to a concrete wall

Drill two 1/4" (6 mm) dia. holes to a minimum depth of

2.5" (64 mm). Attach support arm (A) using concrete

anchors(call customer service to order accessory kit ACC

200 or ACC203)and #14 x 2.5" wood screws (F) as

shown in Illustration A and 1, 2, and 3. Tighten all

fasteners.

1

3

Drill hole and insert anchor

Place wall plate over anchor and secure with screw

After repeating step one tighten all fasteners

CUTAWAYVIEW

INCORRECT

concrete

metal

bracket

plaster/

drywall

CORRECT

concrete

metal

bracket

plaster/

drywall

concrete

wall

concrete

anchor

concrete

anchor

concrete

anchor

F

F

2A

WARNING

• When installing Peerless wall mounts on cinder block, verify that you have a minimum of 1-3/8" of actual concrete

surface in the hole to be used for the concrete anchors. Do not drill into mortar joints! Be sure to mount in a solid

part of the block, generally 1" minimum from the side of the block. Cinder block must meetASTM C-90 specifica-

tions. It is suggested that a standard electric drill on slow setting is used to drill the hole instead of a hammer drill

toavoidbreakingoutthebackof the hole when entering a void or cavity.

• Concrete must be 2000 psi density minimum. Lighter density concrete may not hold concrete anchor.

• Make sure that the wall will safely support four times the combined load of the equipment and all attached hard-

wareandcomponents.

• Tighten wood screws firmly, but do not overtighten.

Overtighteningcandamagethescrews, greatly

reducingtheirholding power.

• Never tighten in excess of 80 in • lb (9 N.M.).

WARNING

• Concrete anchorsare not intendedfor attachment to

concretewallcoveredwithalayerofplaster,drywall,

orotherfinishingmaterial.Ifmountingtoconcretewall

coveredwithplaster/drywallis unavoidable, plaster/

drywall (up to 5/8" thick) must be counterbored as

shown right. If plaster/drywall is thicker than 5/8",

custom fasteners must be supplied by installer.

WARNING

concrete

anchor

F

A

Illustration A