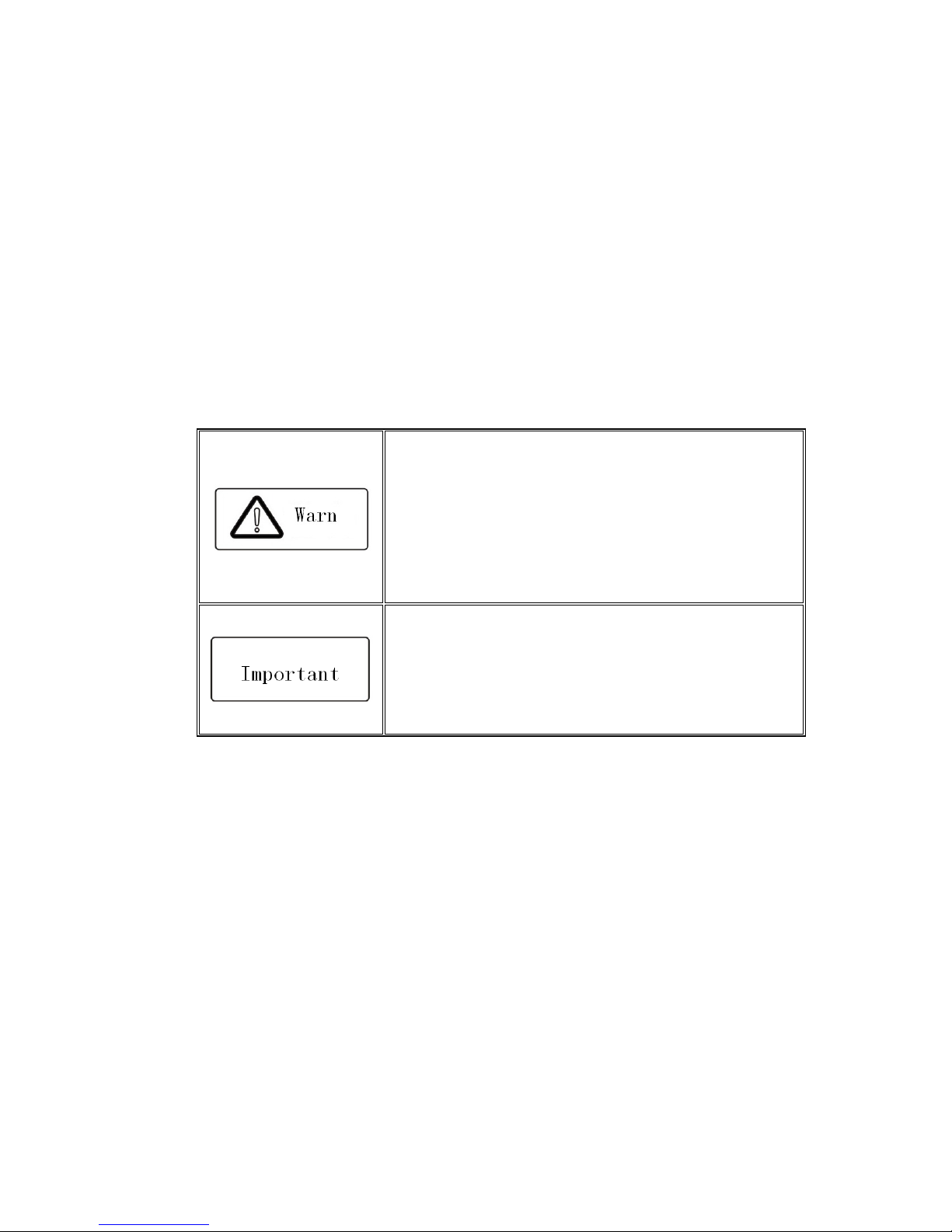

Danger: it ill cause danger of serious injuries and even death hile

operating against the rules

Caution: it ill cause danger of light injuries or equipment

destruction hile operating against the rules

Qualified operation

Only qualified person after professional train can operate the equipment.The operator must be with

professional train, familiar with installation, wiring, running and maintain of equipment, and can deal

emergency case.

Safe guide

Warn sign is for safe, to prevent operator from hurt and prevent this product and relating equipment

from being damaged. Before operating, be sure to carefully read the manual about safety, installation,

operation and maintenance and obey to the safe rules and warn sign.

●

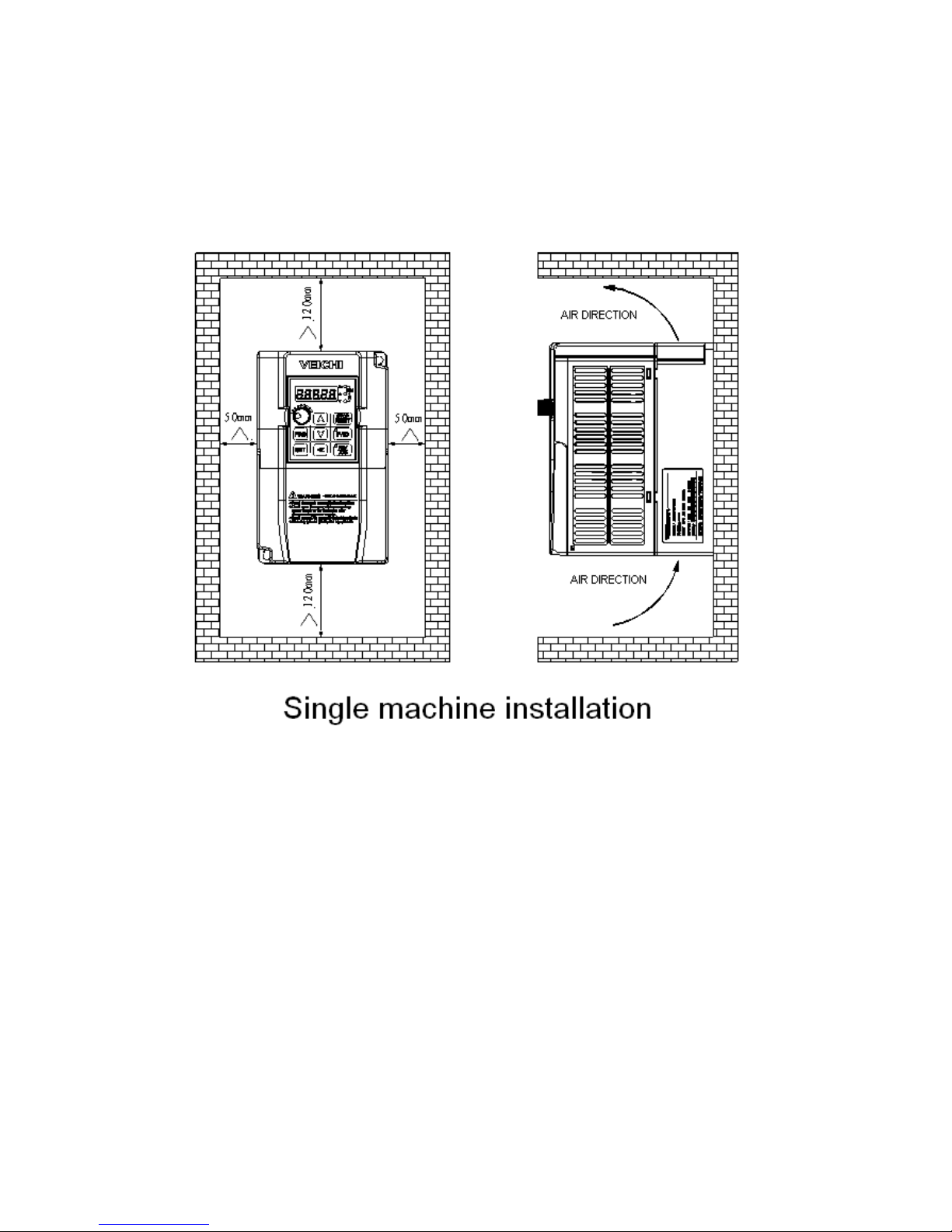

Right transport, store, installation and careful operation and maintenance is most important for inverter safe run. In

transport and store process, make sure the inverter is free from impact and vibration. It must be stored where is dry,

without corrosive air and conductive dust, temperature lower than 60 .

℃

●

This product carries dangerous voltage and controls driver machine with potential danger. If not abide the

regulations or requirements in this manual, there is danger of body injury even death and machine system damage.

●

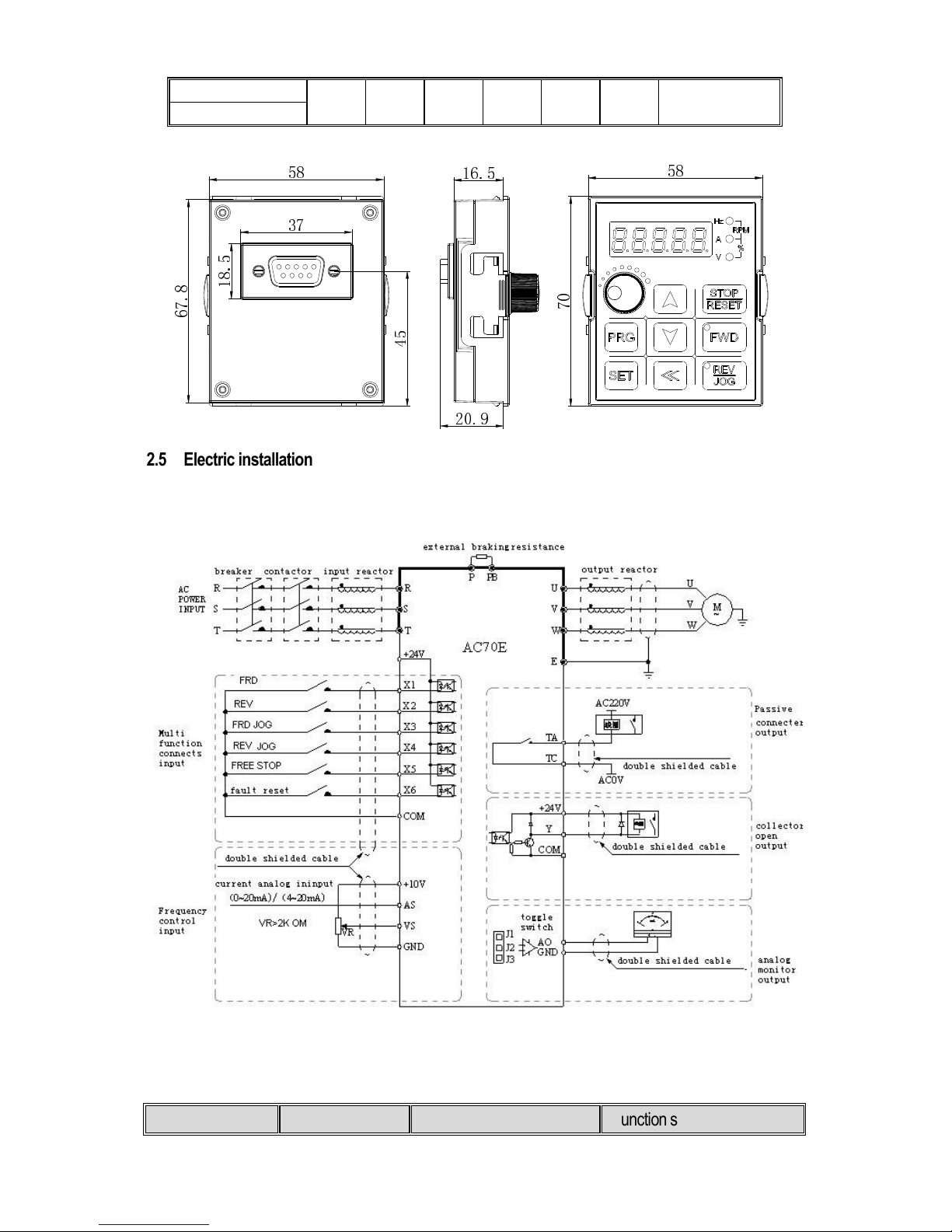

Do not wire while the power is conneted. Otherwise there is danger of death for electric shock. Before wiring,

inspection, maintenance, please cut power supply of all related equipments and ensure mains DC voltage in safe

range. And please do operation after 5 mins.

●

Power wire, motor wire and control wire should be all connected firmly. Earth must be reliable and earth resistance

must be lower than 10Ω.

●

Human body electrostatic will seriously damage inner sensitive components. Before operation, please follow ESD

measures. Otherwise there is danger of iverter damage.

●

Inverter output voltage is pulse wave. If components such as capacitor what improves power factor and

pressure sensitive resistance for anti thunder and so on are installed at the output side, please dismantle or change

to input side.

●

No switch components such as breaker and contactor at the output side. (If there must be one, please make sure

the output current is 0 while the switch acting).

●

No matter where the fault is, there is danger of serious accident, even human body injury what means dangerous

malfunction possibility. So there must be additional external prevent measures or other safety devices, such as

independent current limiting switch, machinery fense and so on.

●

Only used in application fields as maker stated. No use in equipments related to special fields such as emergency,

succor, ship, medical treatment, avigation, nuclear and etc.

●

Only service department of the maker or its authorized service center or professional person trained and authorized