S T / V T V E N D O R •3 5 6 8 3 5 6 7 3 5 6 6 3 5 6 5 •3 4 2 2 0 5 5 7 R e v A

If you have questions concerning the

information in the manual,

replacement parts, or the operation of

the vendor, note your machine’s

Model and Serial Numbers before

contacting:

VendNet

8040 University Blvd

Des Moines, IA 50325 - USA

Parts: (888) 259-9965

Service: (800) 833-4411

Parts Fax: 515-271-8530

www.vendnetusa.com

TABLE OF CONTENTS

INTRODUCTION................................................................................................................................................................................. 4

SPECIFICATIONS ................................................................................................................................................................................ 4

UNPACKING...................................................................................................................................................................................... 5

INSTALLATION .................................................................................................................................................................................. 5

LOADING PRODUCTS ......................................................................................................................................................................... 8

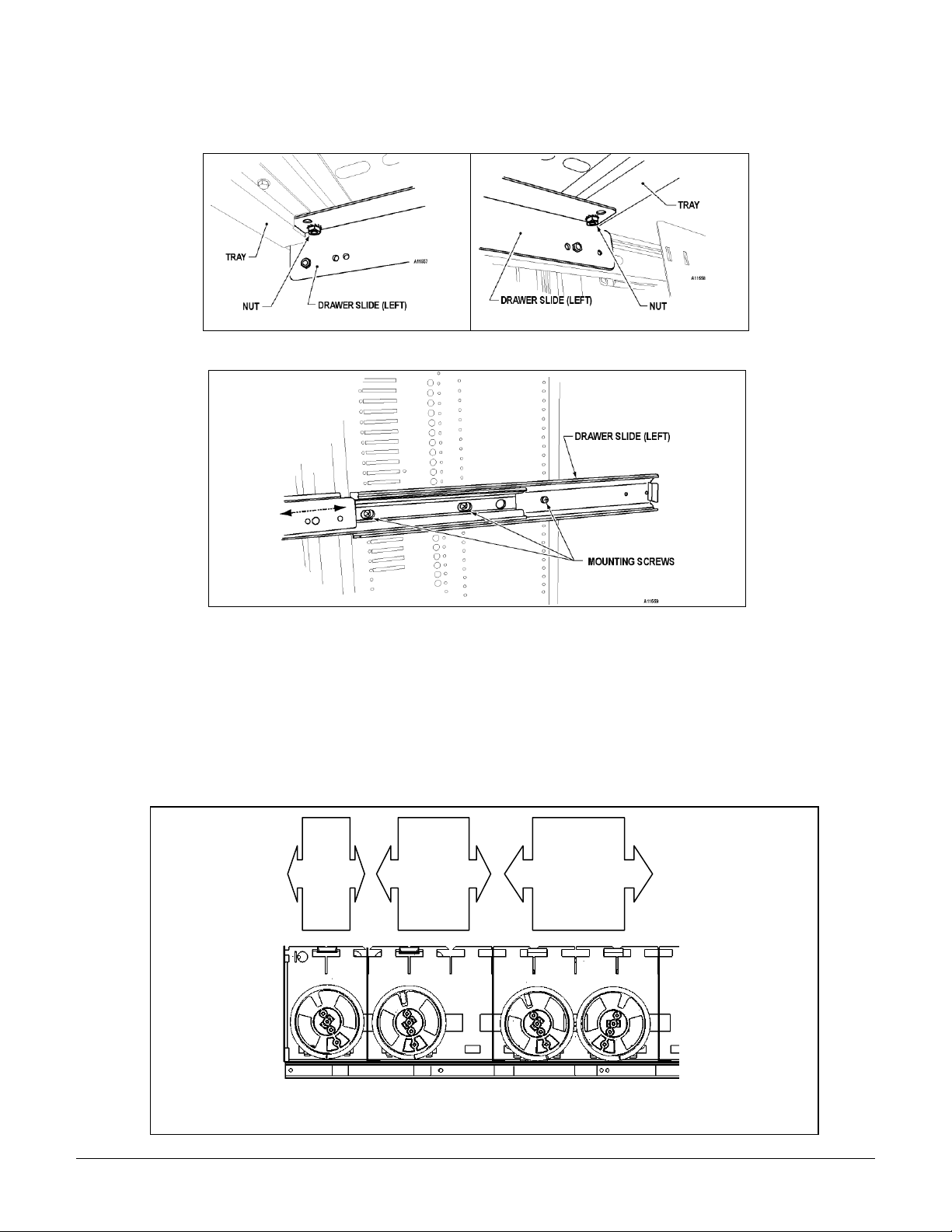

TRAY ADJUSTMENTS.......................................................................................................................................................................... 9

SPIRAL ADJUSTEMENT ..................................................................................................................................................................... 11

AUTOMATIC DELIVERY LIFT .............................................................................................................................................................. 12

VEND CYCLE - IVEND® EQUIPPED ...................................................................................................................................................... 13

SALES MODE................................................................................................................................................................................... 14

BASIC PROGRAMMING SETUP .......................................................................................................................................................... 14

SERVICE MODE ............................................................................................................................................................................... 14

SERVICE MODE FUNCTIONS.............................................................................................................................................................. 15

1TUBE FILL/ DISPENSE COINS ....................................................................................................................................................... 15

2MOTOR COUNT ........................................................................................................................................................................ 15

3 OPTIONS .................................................................................................................................................................................. 15

4 CONFIGURATION ...................................................................................................................................................................... 15

5PRICING ................................................................................................................................................................................... 16

6ACCOUNTING ........................................................................................................................................................................... 17

7ADVANCED OPTIONS................................................................................................................................................................. 17

8TEST VEND - SINGLE MOTOR ...................................................................................................................................................... 17

9TEST VEND ALL MOTORS............................................................................................................................................................ 17

0DIAGNOSTICS ........................................................................................................................................................................... 18

TEMPERATURE CONTROL................................................................................................................................................................. 19

HEALTH SAFETY............................................................................................................................................................................... 21

REFRIGERATION .............................................................................................................................................................................. 22

PREVENTIVE MAINTENANCE............................................................................................................................................................. 25

PARTS ORDERING PROCEDURE ......................................................................................................................................................... 26

BEFORE CALLING FOR SERVICE ......................................................................................................................................................... 27

The Model and Serial numbers are needed for you to obtain quick service and parts

information for your vendor. The numbers are given on the identification plates

located on the back or inside of the vendor. Write them into the spaces below for

your records.

MODEL NUMBER: _______________

SERIAL NUMBER: _______________