Ventis™ MX4 Product Manual

© 2014Industrial Scientific Corporation 2

Table of Contents

COPYRIGHT NOTICE ...................................................................................................................................................3

WARNINGS AND CAUTIONARY STATEMENTS ........................................................................................................3

General ...................................................................................................................................................................3

Personnel ...............................................................................................................................................................3

Hazardous Conditions, Poisons, and Contaminants ..............................................................................................3

General Usage .......................................................................................................................................................4

Agency-issued Conditions of Use and Warnings ....................................................................................................4

Recommended Practices .......................................................................................................................................5

VENTIS MX4™ RESOURCES.......................................................................................................................................6

VENTIS MX4 CAPABILITIES........................................................................................................................................6

UNPACKING THE MONITOR .......................................................................................................................................7

Contents..................................................................................................................................................................7

Reporting a Problem ..............................................................................................................................................7

MONITOR OVERVIEW .................................................................................................................................................8

Hardware Features and Functions..........................................................................................................................8

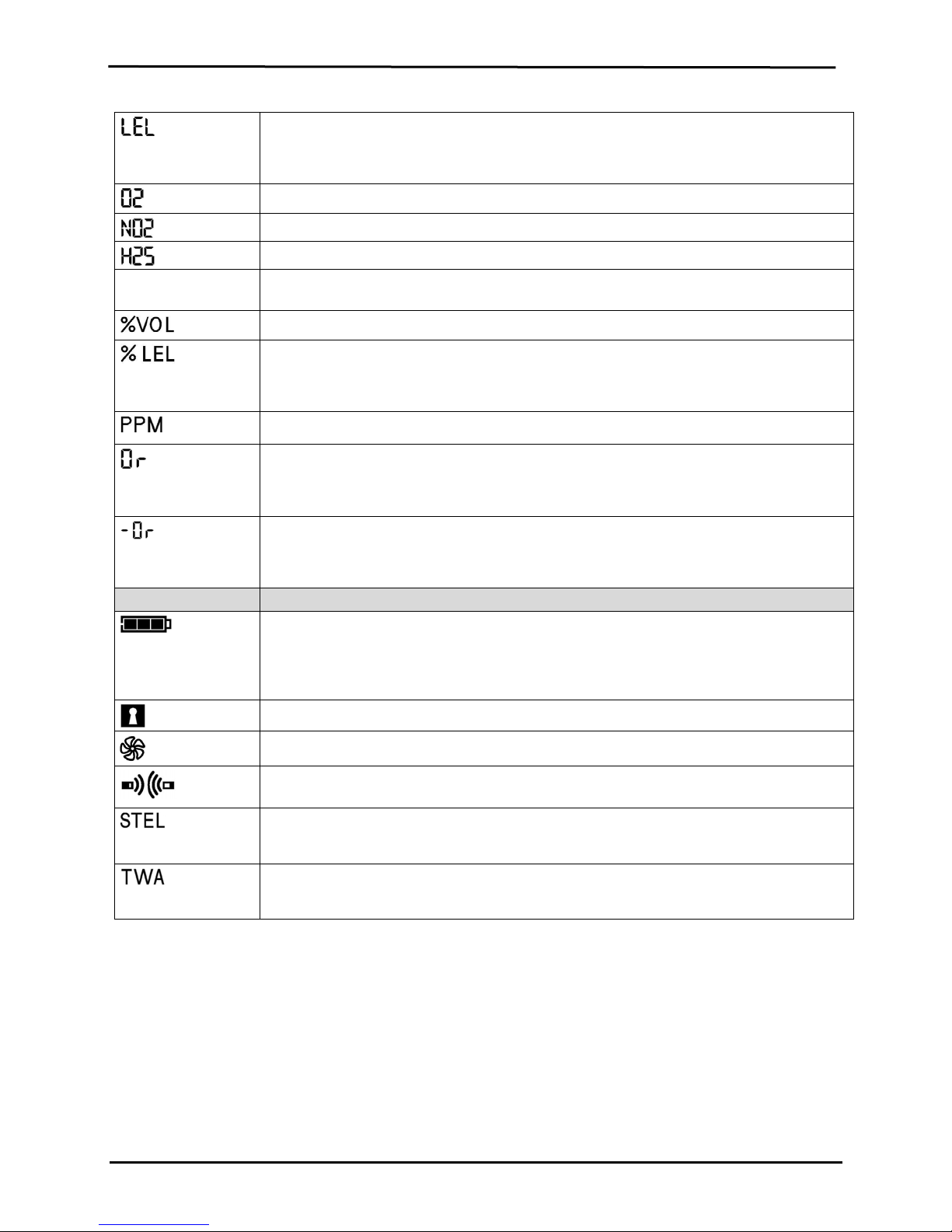

Display Screen........................................................................................................................................................9

Alarms...................................................................................................................................................................11

MONITOR SET-UP ......................................................................................................................................................13

Battery Properties and Monitor Compatibility .......................................................................................................13

Charging the Lithium-ion Battery Packs ...............................................................................................................14

Instruction ......................................................................................................................................................14

Power-on and –off.................................................................................................................................................15

Configuration.........................................................................................................................................................16

Introduction ....................................................................................................................................................16

Instructions ....................................................................................................................................................16

Configuration Process....................................................................................................................................17

MONITOR USE AND SERVICE ..................................................................................................................................24

Zero, Calibration, and Bump Testing ....................................................................................................................24

Procedures ....................................................................................................................................................24

Recommendations.........................................................................................................................................25

General Information ..............................................................................................................................................25

Instructions ...................................................................................................................................................26

Recommended Practices for In-field Air Sampling ...............................................................................................32

Cleaning ...............................................................................................................................................................32

Service..................................................................................................................................................................33

Battery Packs.................................................................................................................................................33

Monitor Conversion .......................................................................................................................................36

Sensor, Sensor Water Barrier, LCD, and Vibrating Motor Replacement........................................................38

Pump Module.................................................................................................................................................40

Ventis MX4 Three-Dimensional View Diagrams ............................................................................................41

PRODUCTS, SPECIFICATIONS, AND CERTIFICATIONS ........................................................................................44

Ventis MX4 Accessories and Parts .......................................................................................................................44

Monitor Specifications...........................................................................................................................................46

Operating Conditions ............................................................................................................................................46

Storage Conditions ...............................................................................................................................................47

Sensor Specifications ...........................................................................................................................................47

Toxic Gas Sensor Cross-Sensitivity Table ............................................................................................................47

LEL and LEL Correlation Factors for Combustible Gases ....................................................................................48

Certifications .........................................................................................................................................................49

WARRANTY ................................................................................................................................................................50

Limitation of Liability..............................................................................................................................................50

INDUSTRIAL SCIENTIFIC CORPORATION GLOBAL LOCATIONS.....................................................BACK COVER