02/2018Edition

8/19U518156‐en‐REV0

ThemainfeaturesoftheEQUALISSflowcomputerarethefollowing:

Graphicdisplay:AnyinformationnecessaryrequiredtousetheEQUALISSisdisplayedonasingle

screen,inawaythatisuser‐friendlyandinteractive.

Dustandwaterresistant:EQUALIShasbeendevelopedandmanufacturedinsuchawayastomake

itresistanttotherisksofeverydayuseandtheelements.

Adjustablemetercurve:TheEQUALIShasaparameterusedtocorrectthecurvebyreducingthe

counterto0‰measurementerroratoperationflowrate.Italsoprovidesthepossibilitytolinearize

thecurvebyusinganerrorcorrectionparameterin6sectors.

Harddiskmemory:Thetransactionsaswellasthesystem’sconfigurationandcalibrationparameters

arebacked‐upinasecuredatabase.Thecapacityofthismemoryallowstosaveupto50000

transactions.

EQUALISSalsoallowsconsultingandreprintingtransactionswhicharestoredinthisdatabase.The

metrologicaldatafeaturedonthisticketisrecognisedbylegalmetrologyauthorities.

Dualchannelsforpulses:EQUALISSmaybeconnectedto1or2pulsetransmitters.Where2pulse

transmittersareconnected,EQUALISSdisplaysthetotalvolumefromthesetwo2counters.

Systematicallyforthis(these)transmitter(s),theEQUALISScounts,storesandcomparesthetwo

pulsechannelsforeachtransmitterwithaphaseshiftof90°.Ifanydisparityisdetectedbetween

their2respectivepulsetrains,thedeliveryisstopped,thusalsopreventinglossofproductduetoa

defectivetransmitter.

ForcompleteinformationaboutEqualisSoperationpleaserefertofollowingtechnicalmanual:

ReferenceTechnicalmanual

U517478EqualisSInstallationmanual

U517504EqualisSProgrammingmanual

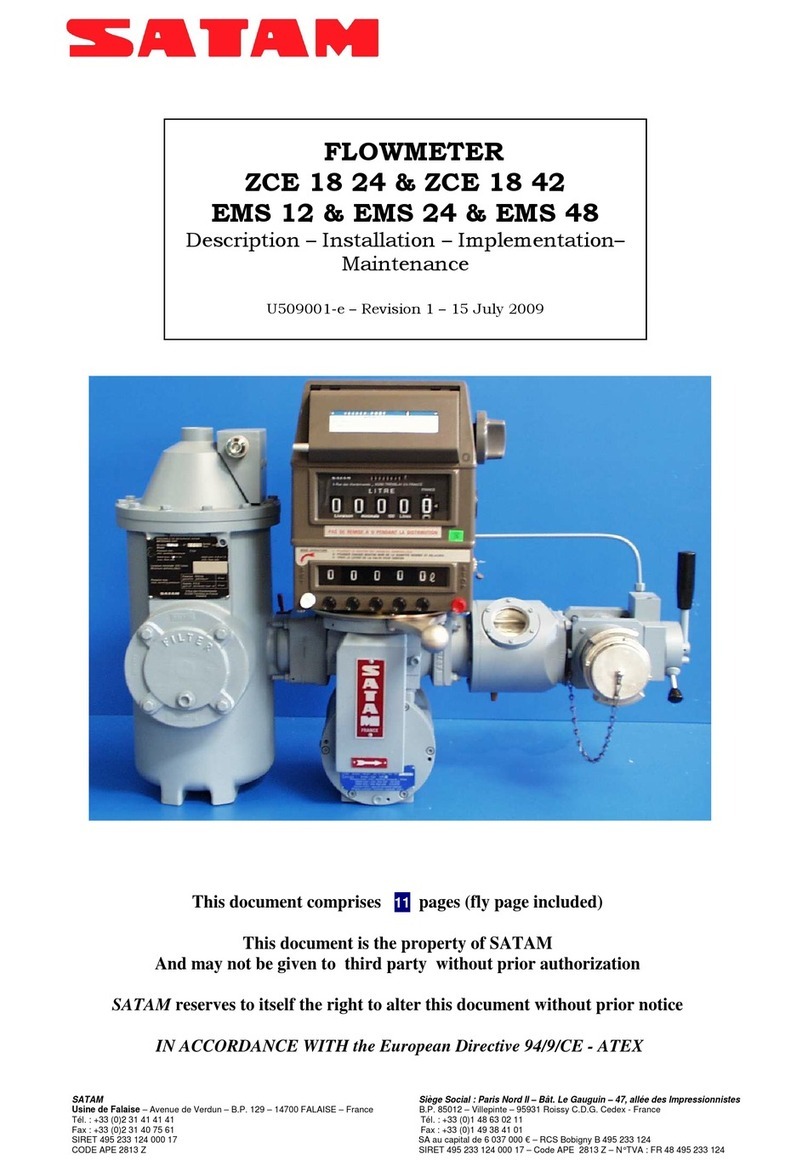

C. Mechanicalregister

Themechanicalregisterisamechanicalindicator.Itdisplaythe

measuredvolumeatoperatingconditions.Theresettablevolume

isdisplayedwith5digitsandthenon‐resettablevolumeis

displayedwith8digits.

Forcompleteinformationaboutmechanicalregisteroperationpleaserefertofollowingtechnical

manual:

ReferenceTechnicalmanual

U508218VR7887Description,installation,operation,servicing