E54C3C Installation Guide

WARNING

LOSS OF CONTROL

∙ Assure that the system will reach a safe state during and after a control path failure.

∙ Separate or redundant control paths must be provided for critical control functions.

∙ Test the eect of transmission delays or failures of communication links.1

∙ Each implementation of equipment using communication links must be individually

and thoroughly tested for proper operation before placing it in service.

Failure to follow these instructions may cause injury, death or equipment damage.

1For additional information about anticipated transmission delays or failures of the link, refer to

NEMA ICS 1.1 (latest edition). Safety Guidelines for the Application, Installation, and Maintenance

of Solid-State Control or its equivalent in your specic country, language, and/or location.

Control system design must consider the potential failure modes of control paths and, for

certain critical control functions, provide a means to acheive a safe state during and after a

path failure. Examples of critical control functions are emergency stop and over-travel stop.

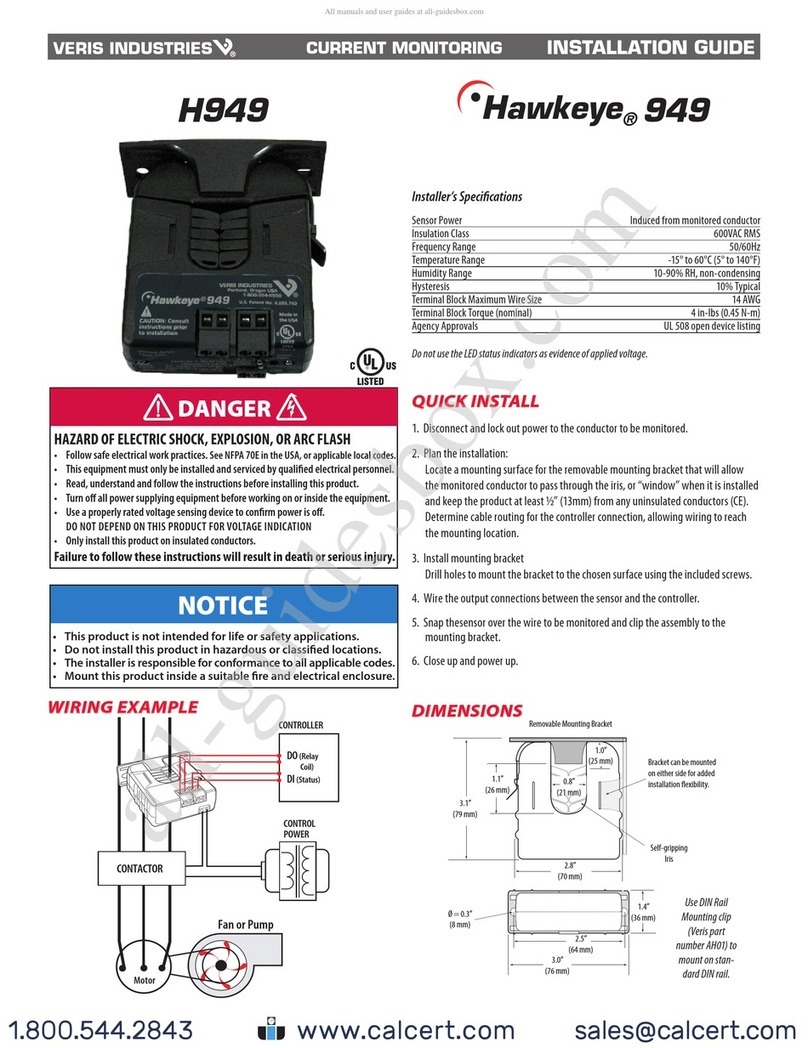

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Follow safe electrical work practices. See NFPA 70E in the USA, or applicable local codes.

• This equipment must only be installed and serviced by qualified electrical personnel.

• Read, understand and follow the instructions before installing this product.

• Turn off all power supplying equipment before working on or inside the equipment.

• Product may use multiple voltage/power sources. Disconnect ALL sources before

servicing.

• Use a properly rated voltage sensing device to confirm that power is off.

DO NOT DEPEND ON THIS PRODUCT FOR VOLTAGE INDICATION.

• Current transformer secondaries must be shorted or connected to a burden at all times.

• Products rated only for basic insulation must be installed on insulated conductors.

• Replace all doors, covers and protective devices before powering the equipment.

Failure to follow these instructions will result in death or serious injury.

A qualied person is one who has skills and knowledge related to the construction and

operation of this electrical equipment and installations, and has received safety

training to recognize and avoid the hazards involved. NEC Article 100

If this product is used in a manner not specied by the manufacturer, the protection

provided by the product may be impaired. No responsibility is assumed by the

manufacturer for any consequences arising out of the use of this material.

DANGER

For use in a Pollution Degree 2 or better environment only. A Pollution Degree 2 environment

must control conductive pollution and the possibility of condensation or high humidity.

Consider theenclosure, thecorrect useof ventilation,thermal properties ofthe equipment,

and the relationship with the environment. Installation category: CAT II or CAT III. Provide

a disconnect device to disconnect the meter from the supply source. Place this device in

close proximity to the equipment and within easy reach of the operator, and mark it as the

disconnecting device.The disconnecting device shallmeet the relevantrequirements of

IEC 60947-1 and IEC 60947-3 and shall be suitable for the application. In the US and Canada,

disconnecting fuse holders canbe used. Provideovercurrent protection and disconecting

device for supply conductors with approved current limiting devices suitable for protecting the

wiring. If the equipment is used in a manner not specied by the manufacturer, the protection

provided by the device may be impaired.

NOTICE

• This product is not intended for life or safety applications.

• Do not install this product in hazardous or classied locations.

• The installer is responsible for conformance to all applicable codes.

• Mount this product inside a suitable re and electrical enclosure.

FCC PART 15 INFORMATION

NOTE: This equipment has been tested by the manufacturer and found to

comply with the limits for a class B digital device, pursuant to part 15 of

the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a

residential environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio

communications. This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including

interference that may cause undesired operation.

Modifications to this product without the express authorization of the

manufacturer nullify this statement.

Installation Guide

Power Monitoring TMTM

The safety of any system incorporating this equipment is the responsibility of the

assembler of the system.

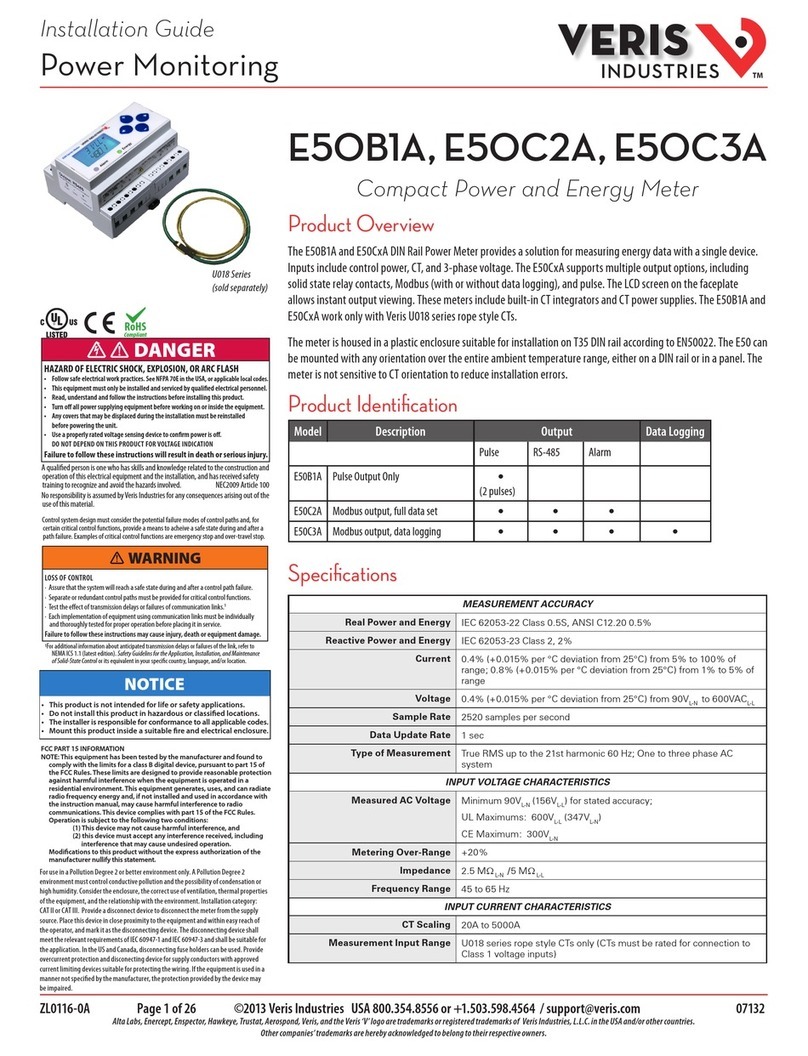

Product Overview

The E54C3C energy meter works on a on a single-phase, three-phase, or three-phase + neutral network with

partial metering and reset functions. The meter requires 1 Amp or 5 Amp current transformers. Data values are

instantly accessible using either the local display or the communications network. The E54C3C is equipped with

Modbus communication via RS-485. It provides four-quadrant energy measurements with one congurable

digital input, one congurable digital output, and up to four taris.

Important: COM.Protection is a mode that prevents changes to any meter setting related to energy

measurement, such as wiring conguration, through Modbus communication. This mode is enabled by default.

To allow conguration over Modbus, rst disable COM.Protection via the conguration menu on the display.

Refer to the Conguration section of this guide.

E54C3C

Energy Meter, Modbus Communication

Specications

POWER SUPPLY

Measured Voltage 100 to 277 VLN; 173 to 480 VLL ± 20%

Frequency 50/60 Hz ± 10%

Voltage Impedance 3 MΩ

Wire Size 24 to 14 AWG (0.2 to 2.5 mm2)

Terminal Block Torque 4.4 in-lb (0.5 N-m) max.

CURRENT INPUTS

Nominal Current 1 A or 5 A

Measured Current 5 mA to 6 A

Withstand 10 A continuous; 20 A @ 10 sec/hr

Frequency 50/60 Hz ± 10%

Impedance <0.3 mΩ

Burden <0.024 VA @ 10 A

Wire Size 18 to 10 AWG (0.8 to 6 mm2)

Terminal Block Torque 7.0 in-lb (0.8 N-m) max.

DIGITAL INPUT

Type Type 1 (IEC 61131-2)

Maximum Input 40 Vdc, 4 mA

Voltage O 0 to 5 Vdc

Voltage On 11 to 40 Vdc

Nominal Voltage 24 Vdc

Isolation 3.75 kV RMS

Wire Size 25 to 16 AWG (0.14 to 1.5 mm2)

Terminal Block Torque 4.4 in-lb (0.5 N-m) max.

DIGITAL OUTPUT

Type SPST N.O. (Form A)

Maximum Input 5 to 40 Vdc, 50 mA

Output Resistance 0.1 to 50 Ω

Wire Size 25 to 16 AWG (0.14 to 1.5 mm2)

Terminal Block Torque 4.4 in-lb (0.5 N-m) max.

MEASUREMENT ACCURACY

Real Energy for x/1A Current Input Class 1 conforming to IEC 62053-21 and IEC 61557-12

(PMD Sx): Imax=1.2 A, ln=1 A, and Ist=0.002 A

Class B conforming to EN 50470-3: Imax=1.2 A, ln=1 A, Imin=0.01 A, and

Ist=0.002 A

Reactive Energy for x/1A Current Input Class 2 conforming to IEC 62053-23 and IEC 61557-12

(PMD Sx): Imax=1.2 A, ln=1 A, and Ist=0.003 A

Real Energy for x/5A Current Input Class 0.5S conforming to IEC 62053-22 and IEC 61557-12 (PMD SD):

Imax=6 A, ln=5 A, and Ist=0.005 A

Class C conforming to EN 50470-3: Imax=6 A, ln=5 A, Imin=0.05 A, and

Ist=0.005 A

Reactive Energy for x/5A Current Input Class 2 conforming to IEC 62053-23 and IEC 61557-12

(PMD Sx): Imax=6 A, ln=5 A, and Ist=0.015 A

MODBUS COMMUNICATION

Number of Ports 1

Parity Even, Odd, None

Baud Rate 9600, 19200, 38400

Isolation 4 kV RMS

Wire Size 24 to 14 AWG (0.2 to 2.5 mm2)

Terminal Block Torque 4.4 in-lb (0.5 N-m)

OPERATING CONDITIONS

Operating Temperature Range -25 to 55 °C (-13 to 131 °F) (5% to 95% RH non-condensing)

Storage Temperature Range -40 to 85 °C (-40 to 185 °F)

Altitude of Operation < 2000 m

Mounting Location Not suitable for wet locations. For indoor use only.

COMPLIANCE INFORMATION

Approvals CE; UL 61010-1; IEC/EN 61010-1; IEC 62053-31

Housing IP40 front panel, IP20 casing, Pollution Degree 2, IK08 impact rating

MID 2004/22/EC compliance

Specications (cont.)

Dimensions

3.5”

(90 mm)

4.0”

(102 mm)

2.7”

(69 mm)

2.5”

(64 mm)

3.4”

(87 mm)

1.8”

(45 mm)

OK ESC

ZL0131-0G Page 1 of 8 ©2018 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 0818

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Aerospond, Veris, and the Veris ‘V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C. in the USA and/or other countries.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

EAV71194-04

ZL0131-0G Page 2 of 8 ©2018 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 0818

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Aerospond, Veris, and the Veris ‘V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C. in the USA and/or other countries.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

EAV71194-04

E54C3C