2

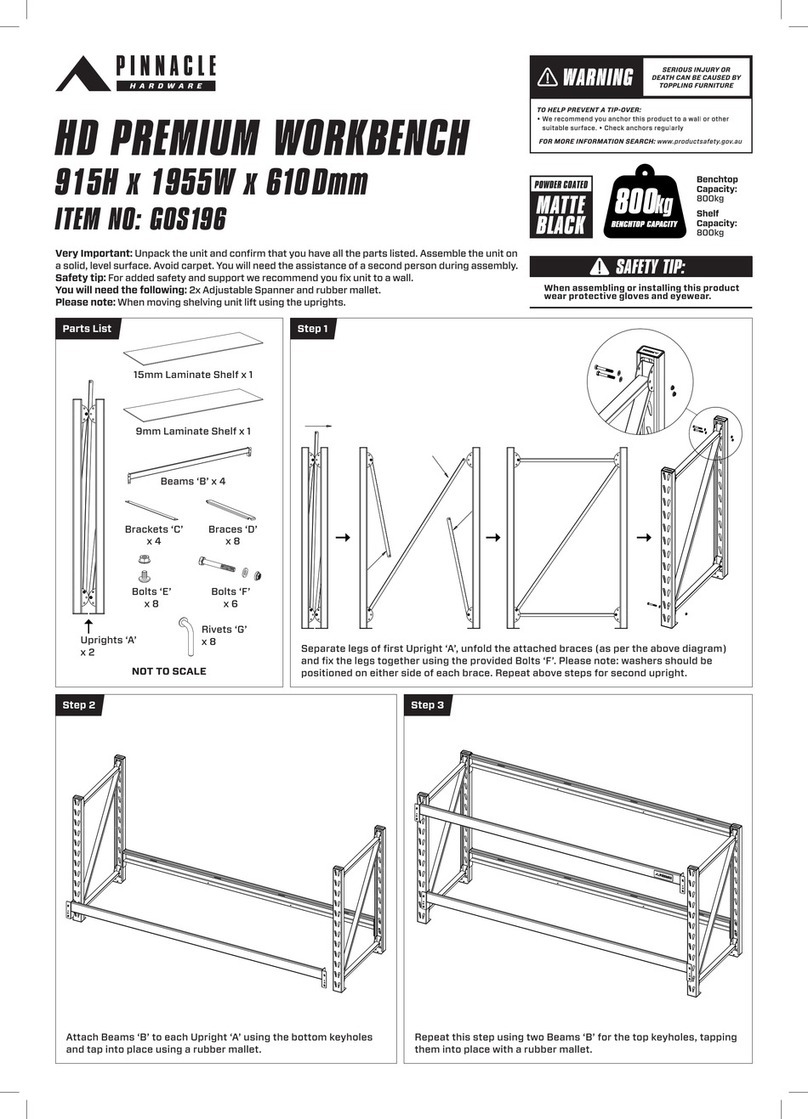

Top Assembly

4. Near each end of the upper rails on the trestles there

is a hole. These are used to fasten the bench top,

which has four mating pilot holes, to the base. Place

the bench top over the base, aligning the mounting

holes. Using a 9/16"socket or wrench, secure the top

to the base with four 3/8"× 3"lag screws and flat

washers. Firmly tighten the eight hex nuts holding

the base together, and cover the counterbores with

the plastic caps provided. Adjust the levelling feet as

required to eliminate any rocking.

5. Slide the front vise into the holes in the front vise

jaw and, using a #3 Robertson®screwdriver (square

drive), fasten the two together with three #14 × 11/2"

flat-head screws. Wind the front vise jaw assembly

into the mating holes located on the left front corner

of the bench.

6. Install the Veritas®Twin-Screw Vise following the

instructions provided with it.

7. Install the three vise handles onto the vise tees, using

a #2 Phillips screwdriver to fasten the end caps.

Note: One of the handles is equipped with a speed knob;

this is intended to fit onto either tee of the twin-screw

vise for faster opening and closing.

Using your Veritas®Workbench

The Veritas®Workbench, with its Veritas® Twin-Screw

Vise, front vise, matrix of mating 3/4"bench dog holes and

four brass bench dogs, provides an extremely versatile

work surface with many clamping possibilities.

The twin-screw vise has some features that may not be

obvious. Besides its two clamping screws that eliminate

all possibility of racking, a spring-loaded drive/lock

pin lets you disengage the connecting chain drive for

controlled skewing needed to equalize pressure on

slightly out-of-square work. This is activated by simply

pulling back on the brass knob located on the right-

hand tee. Disengaging the drive/lock pin lets you turn

either screw independently of the other to produce the

required skew.

Warning: The vise should never be skewed more

than one full turn in either direction.

To realign the jaws, turn the handle you moved in the

opposite direction (back to how it was) and you will

hear and see the drive/lock pin “click” back into place.

If you try to disengage the pin with the jaws clamped

tight, you may find that you have to first slacken the vise

screw containing the pin.

The drive/lock pin also acts as a shear pin. If you apply

excessive force to either screw, the pin will shear before

the vise becomes damaged. A spare pin is enclosed

should this ever occur. An exploded view of the twin-

screw vise is shown in Figure 2.

Main Chain Cover

Set Screws

Chain Cover End Cap

To balance the chain,

squeeze together in the

center before tightening

the set screws.

Balancing the chain

prevents it from skipping

a tooth on the sprocket.

Tee

Figure 2: Veritas®Twin-Screw Vise. Figure 3: Balancing the chain on twin-screw vise.