Tester, Combination, 3-State

Operation, Installation and Maintenance

Pass Range 750K - 35M

UNIT C, 4TH DIMENSION, FOURTH AVENUE, LETCHWORTH, HERTS, SG6 2TD UK

Phone: 0044

(0) 1462

672005, Fax:

0044 (0)

1462 670440

• e-mail:

[email protected], Internet:

Vermason.co.ukTB-7533 October 2009 Page 1 of 4 © 2009 Vermason

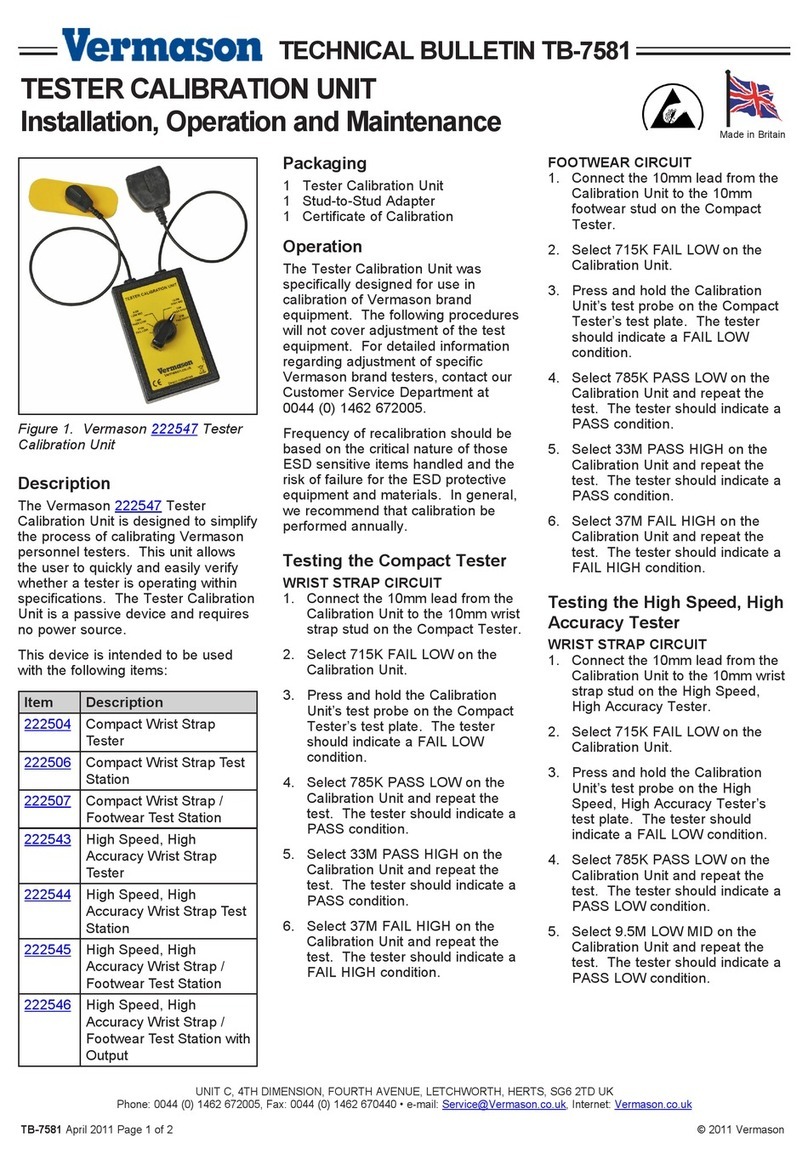

Figure 1. Vermason 222610 Combo Tester

Description

The Vermason Combo Tester is a 3-state

touch tester designed for fast and frequent

testing of ESD personnel grounding devices.

The Combo Tester incorporates a unique

dual test circuit design which improves

accuracy of testing and eliminates the need

for separate wrist strap and foot grounder

test units. The 222610 is equipped with a

750 Kilohm - 35 Megohm circuit, ideal for the

testing of wrist straps and footwear.

Test parameters are factory set but can be

adjusted to match your own specifications.

The Combo Tester is very simple to operate.

A green light signals the user that everything

is OK. A red light and an audible indicator

means that the circuit resistance is either too

low or too high.

The testers each include a

convertor, which converts the

banana plug on the face of

the unit into a 10mm snap.

NOTE: Once the convertor

has been put into the plug socket it cannot

be removed.

“The primary means of grounding personnel

shall normally be by a wrist strap connected

to an EBP [Earth Bonding Point].” (EN

61340-5-1 paragraph 5.5) “Wrist straps shall

be checked before use. Each check shall

be made with the wrist band worn in contact

with the wearer’s skin and with the ground

cord attached to the appropriate tester.” (EN

61340 5-1 paragraph 9.6) “The wrist strap

shall consist of a band that fits snugly around

the wrist and a cord to connect the band

to an EBP...The total resistance from hand

to EBP shall be in accordance with table

1 [Rg 7,5 x 10^5 to 3,5 x 10^7 ohms]. (EN

61340-5-1 paragraph 5.2.7)

“All wearers shall check that their heel and

toe straps meet requirements. The check

shall be made before entering the EPA.”

(EN 61340 5-1 paragraph 9.6.3) “When

the footwear/floor systems are used as the

primary means of grounding personnel,

the resistance of the combination shall be

determined by the ESD co-ordinator, and

is recommended to be between 7,5 x 10^5

ohms and 3,5 x 10^7 ohms.” (EN 61340-5-1

Table 1 Note 2)

The tester operates on either a 9 volt battery

or a special AC adapter. The combo tester

is available in two models: the tester alone,

or the tester with a stand. A footplate is also

available for use with the 222610.

CAUTION: Use only the AC adapter

designed for this unit. Using any other

adapters may damage the unit and void the

warranty.

Inspection

Remove the tester from the carton and

inspect for damage.

Items included with model 222610:

1 Combo Tester

1 9 volt battery

1 converter

1 Certificate of NIST calibration

Items included only with model 222611:

1 Combo Tester

1 Base Plate

1 Pedestal tube with bracket and boot

installed

1 10cm banana plug connector

1 Vinyl insulator cap

1 Wall poster

1 5/32” hex wrench

1 9 volt battery

1 converter

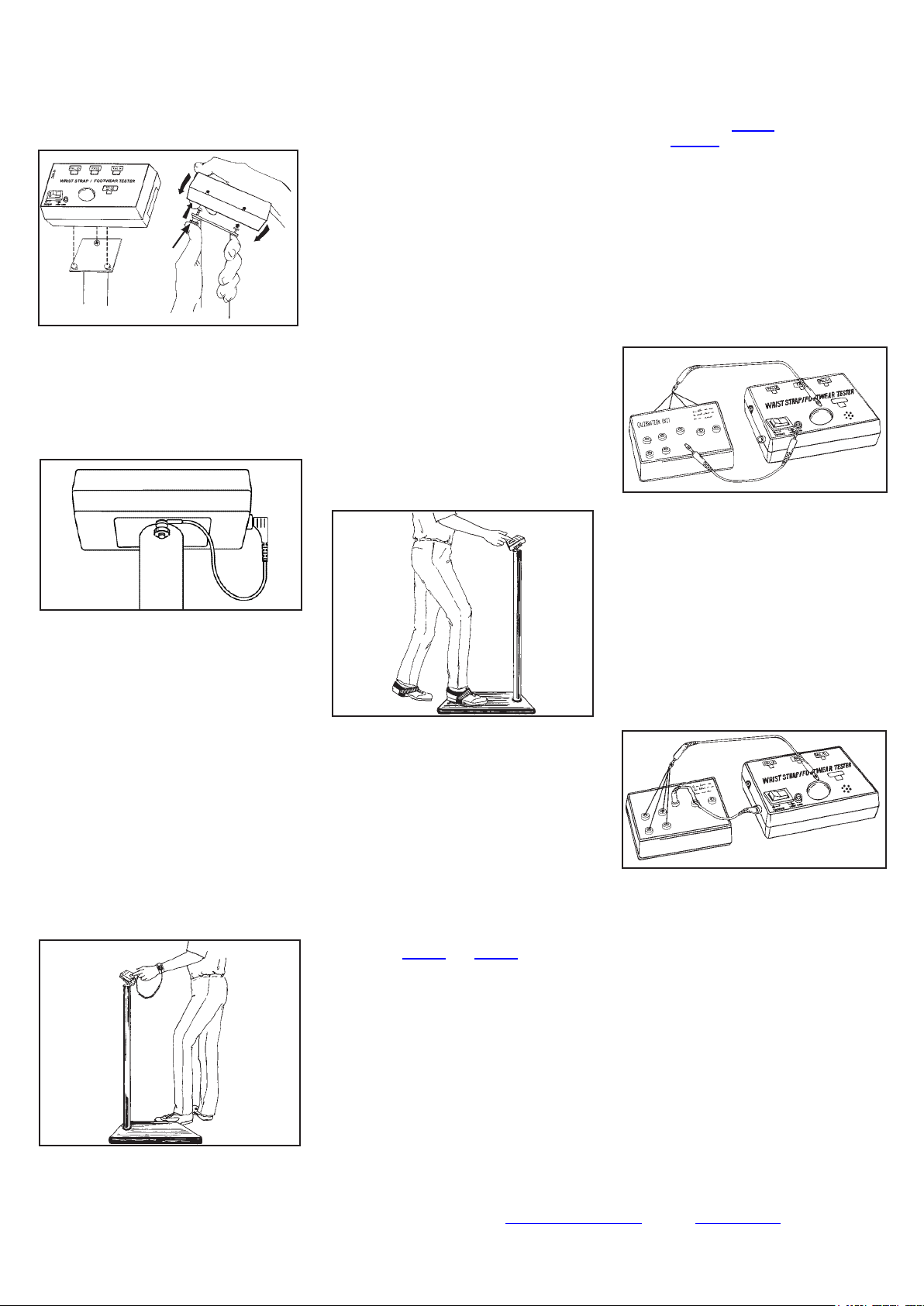

Model number 222611 is ideally suited for

testing foot grounding devices. Item number

222612 can also be used in conjunction with

the combo tester for testing of footwear.

Installation of Model 222610

The Combo Tester may be used as a

portable unit, or may be permanently

mounted on either a table or a wall. Please

refer to the following instructions when

installing your tester.

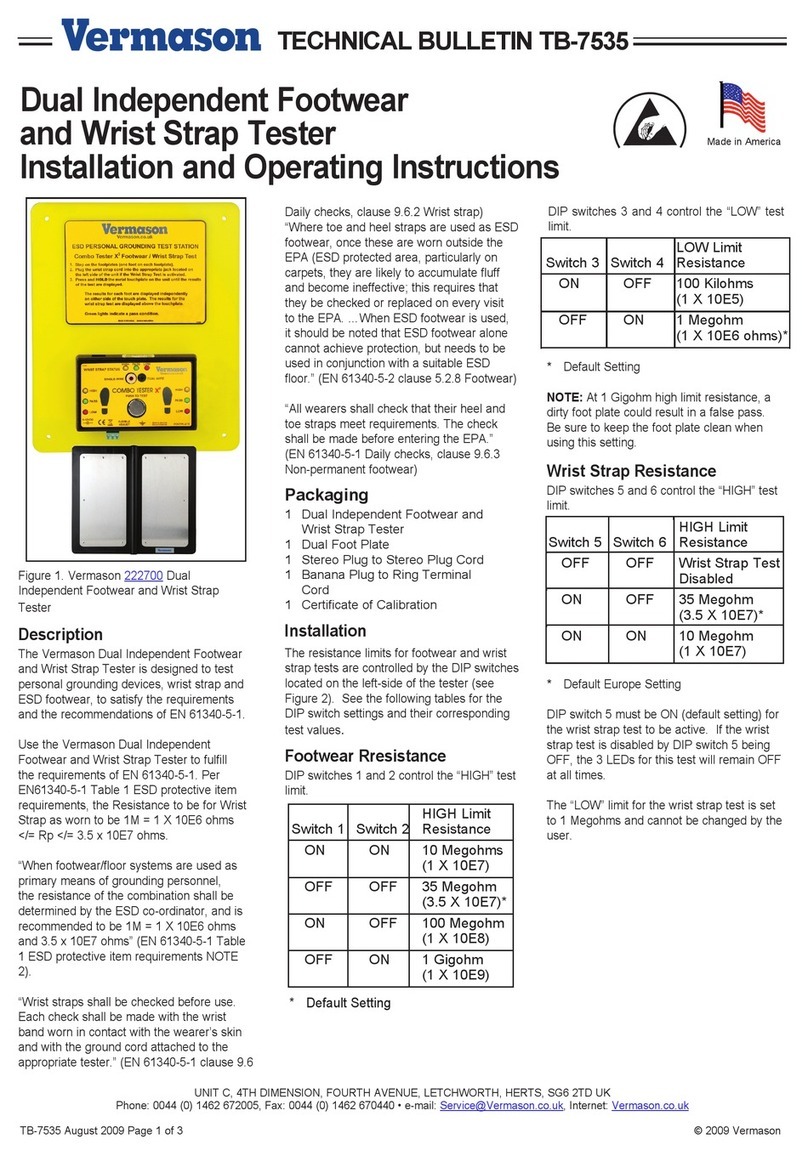

Stationary Installation

If you will be using the tester as a portable

unit you may prefer to mount the unit to a

table or wall. Three keyhole slots on the back

of the unit are included to allow you to attach

the tester to a stationary surface.

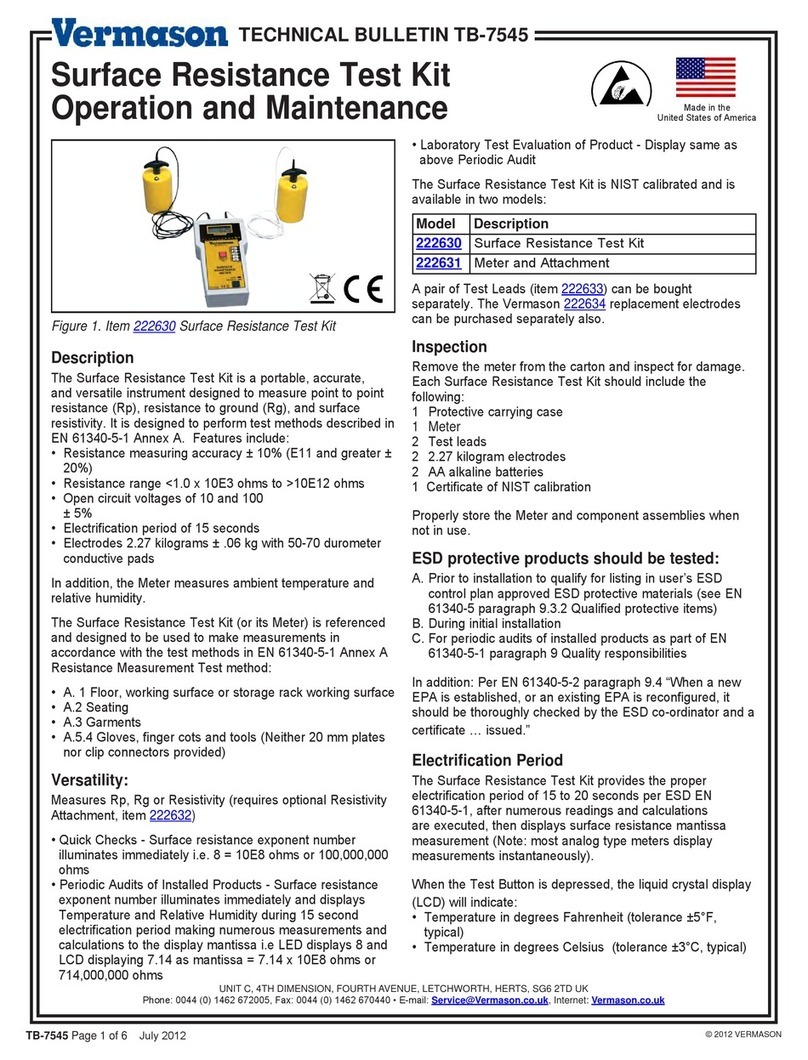

Figure 2. Mounting hole locations

1. Select location for mounting tester. Install

three #6 or #8 screws spaced as illustrated

in figure 3, into a wall or other vertical

surface. Make sure that the screw heads

do not project out more than 6.35 mm from

mounting surface. The template on page four

is actual size.

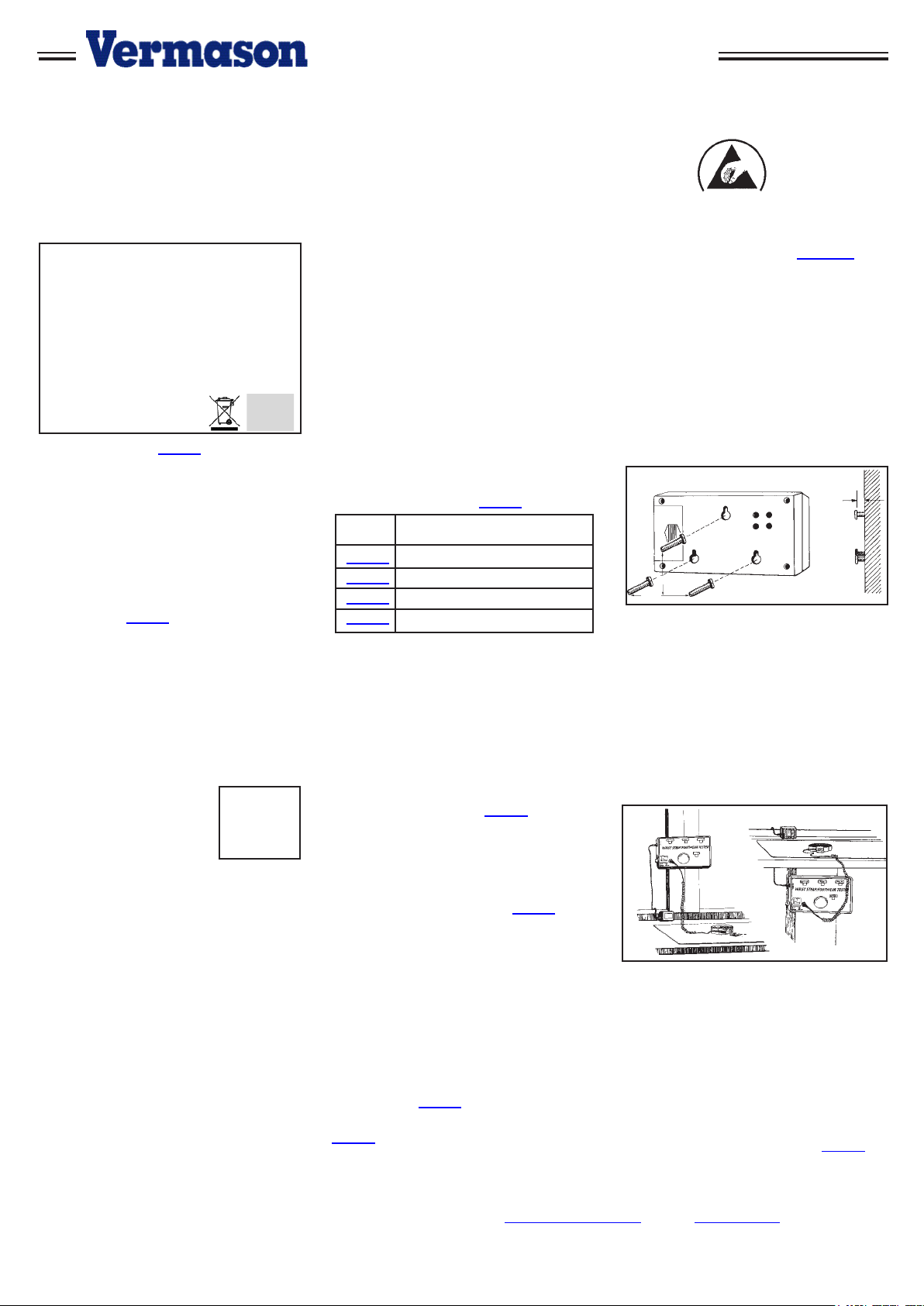

2. Mount the tester on the screws, pulling

down to lock it in place.

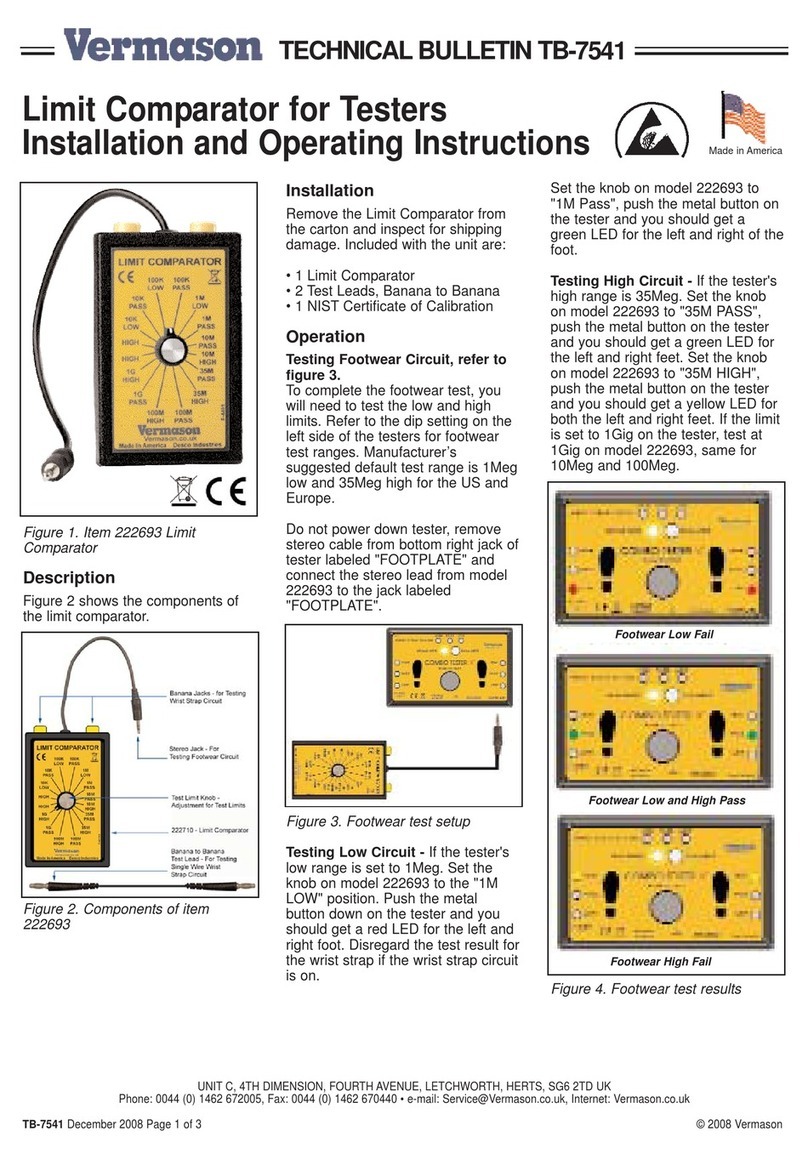

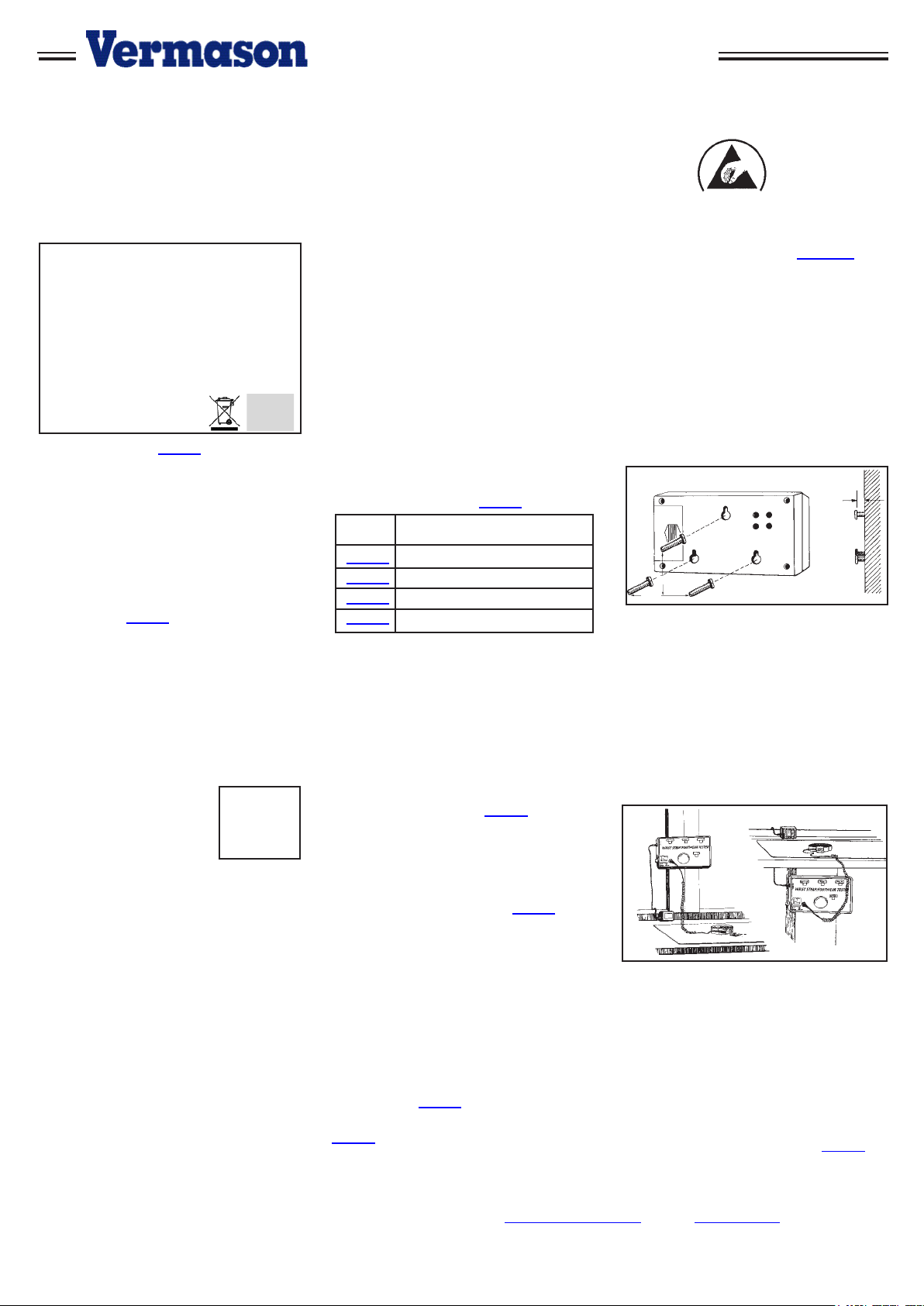

Figure 3. Stationary installation of the Combo

Tester

Operation

The Combo Tester can be operated either

on battery or AC power. The unit comes

equipped with a 9 volt alkaline battery. For

AC operation, plug the optional AC adapter

into the mini phone jack located on the upper

left hand corner of the tester. An AC adapter

is sold separately as item number 222625

(220 volt).

Model Description

222610 Tester, Banana Jack

222611 Tester w/stand

222612 Footplate, stainless steel

222625 AC Adapter, 220V

60mm

41mm

6mm

TECHNICAL BULLETIN TB-7533

Made in the

United States of America