HIGH SPEED, HIGH ACCURACY PERSONNEL

TESTER AND STAND

Installation, Operation and Maintenance

UNIT C, 4TH DIMENSION, FOURTH AVENUE, LETCHWORTH, HERTS, SG6 2TD UK

Phone: 0044 (0) 1462 672005, Fax: 0044 (0) 1462 670440 • e-mail: Service@Vermason.co.uk, Internet: Vermason.co.uk

TB-7536 December 2008 Page 1 of 2 © 2008 Vermason

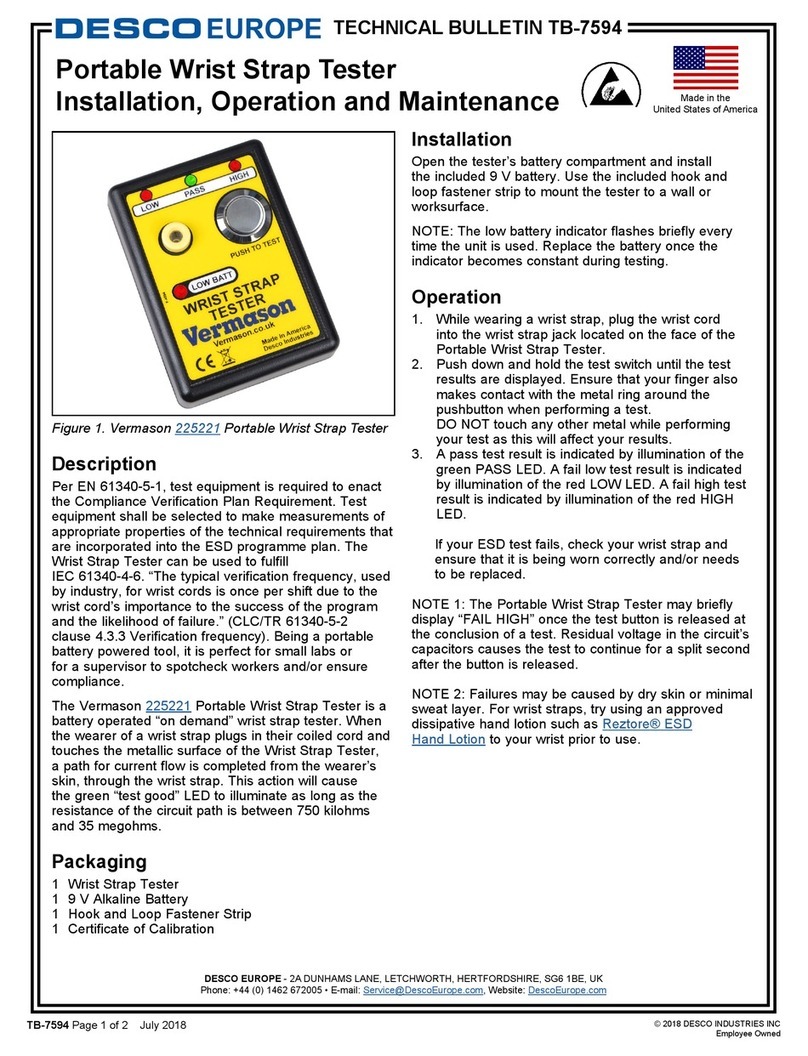

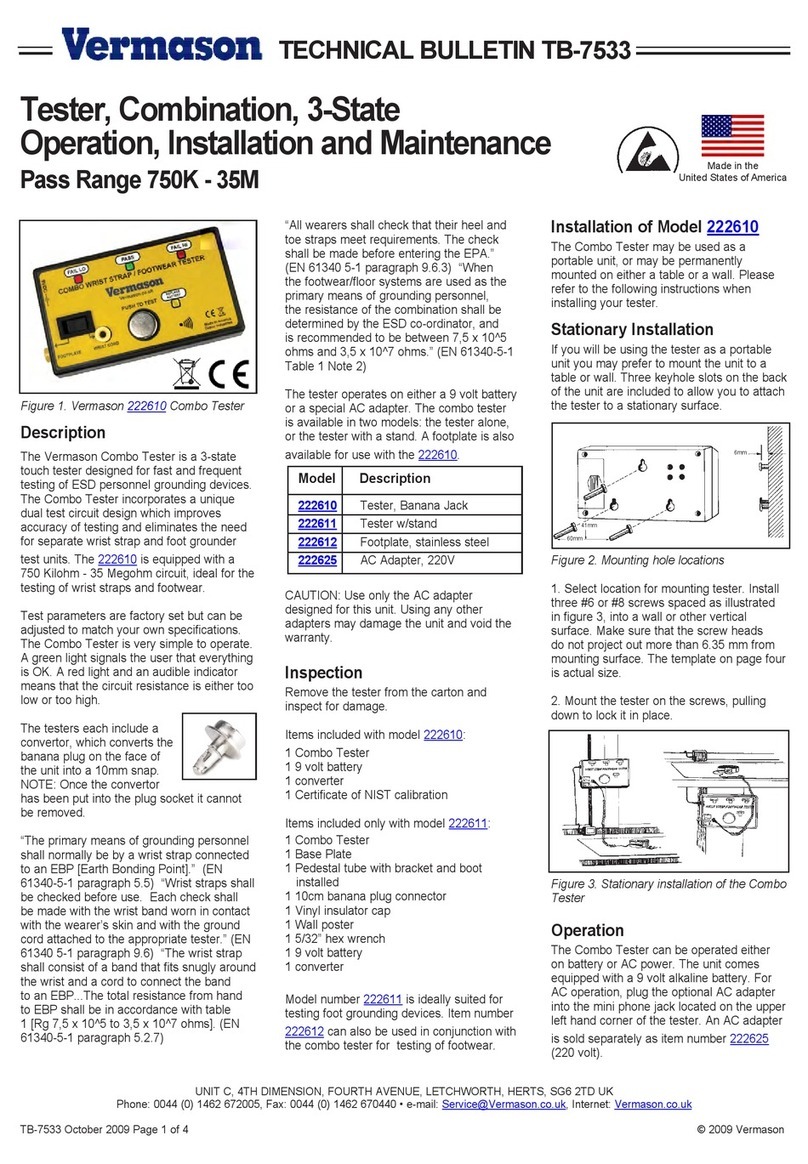

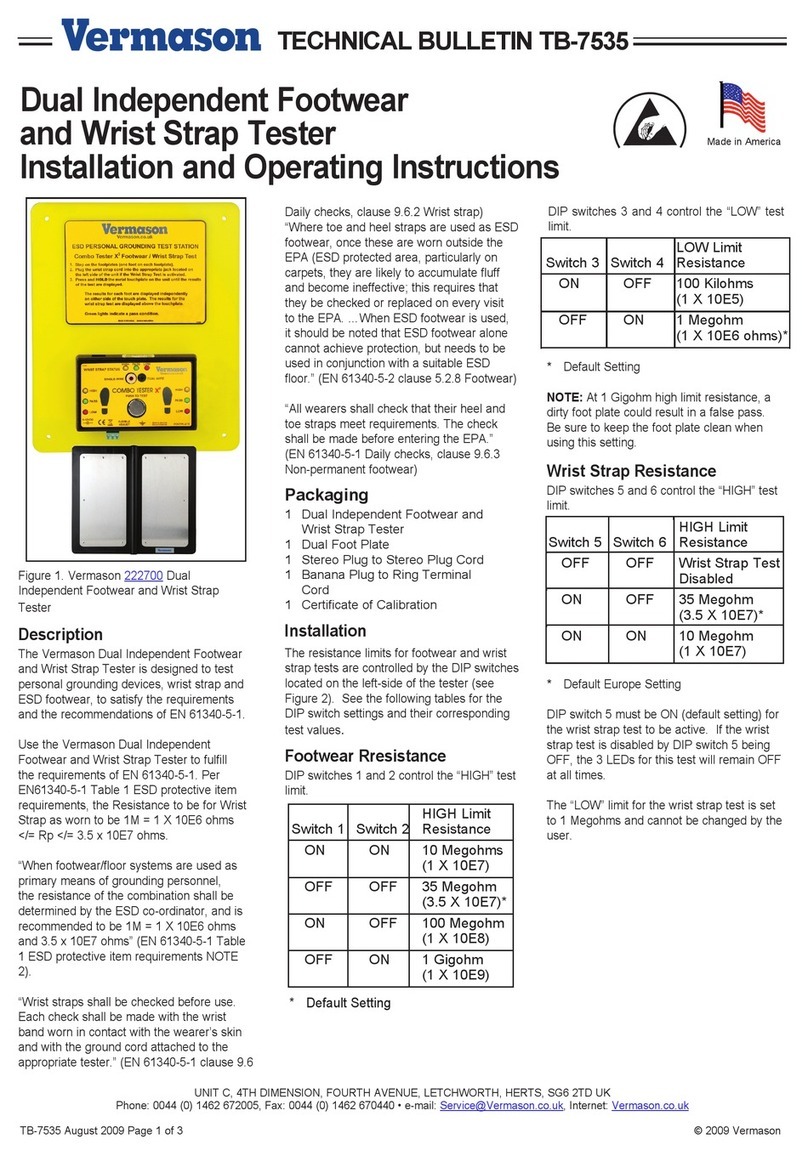

Figure 1. 222523 Personnel Test

Stand.

Description

A digital instrument with a

programmable IC at its heart that will

test the resistance of an operator's

grounding system(s) mounted on a

black metal frame with a black

wooden base board. The 222522 will

test the operator's ESD footwear.

The 222523 will additionally test the

operator's wrist strap. The stations

test both feet simultaneously. The

instrument will indicate whether the

resistance is in the ranges specified

in EN 61340-5 and ANSI/ESD S1.1 &

S20.20.

“Wrist straps shall be checked before

use. Each check shall be made with

the wrist band worn in contact with

the wearer's skin and with the ground

cord attached to the appropriate

tester.” (EN 61340 5 1 paragraph 9.6

Daily checks, paragraph 9.6.2 Wrist

strap) “Where toe and heel straps

are used as ESID footwear, once

these are worn outside the EPA [ESD

protected area], particularly on

carpets, they are likely to accumulate

fluff and become ineffective; this

requires that they be checked or

replaced on every visit to the EPA.

…When ESD footwear is used, it

should be noted that ESD footwear

alone cannot achieve protection, but

needs to be used in conjunction with

a suitable ESID floor.” (EN 61340-5-2

Paragraph 5.2.8 Footwear) “All

wearers shall check that their heel

and toe straps meet requirements [of

Table 1 NOTE 2 – ‘When the

footwear/floor systems are used as

the primary means of grounding

personnel, the resistance of the

combination shall be determined by

the ESD co-ordinator, and is

recommended to be between 7,5 x

10E5 ohms1 and 3,5 x 10E7 ohms’].

The check shall be made before

entering the EPA.” (EN 61340 5-1

Daily checks, paragraph 9.6.3 Non-

permanent footwear)

Inspection

Remove the test unit from the carton

and inspect for shipping damages.

Each 222522 unit should include the

following:

1 Test unit, item #222522

1 Test Stand Assembly

Each 222523 unit should include the

following:

1 Test unit, item #222523

1 Test Stand Assembly

Installation

1. Remove the components from the

packaging.

2. Lay out the baseboard and upright

bar using the packaging to protect

the paintwork.

3. Stand the baseboard on the rear

edge and offer the upright to

connect the 2 leads and align the

4 bolt holes.

4. With the leads connected, feed the

surplus cord back into the upright,

and then fit the four bolts from the

top. The washers and nuts can

then be fitted and tightened.

5. Stand the test stand up.

6. Insert the tester plugs through the

two larger holes in the instruction

panel. The connectors on the back

of the tester fit into the sockets on

the upright.

7. Place both in position, using the

two M5 bolts to secure the tester

& panel to the upright.

8. Perform a check on each plate

individually to check the

connections. If practical, remove a

shoe and stand in stockinged feet

on one footplate. Perform a test -

you should obtain a pass or fail

low. (Most likely fail low). Repeat

the test with the foot on the other

test plate.

9. The test station is now ready for

use.

Procedure to test footwear

1. Wear ESD shoes or heel

grounders as prescribed.

2. Stand on the footplates.

3. Press the round metal button on

the tester with one or two fingers.

The tester will now indicate

whether the total resistance is

within the acceptable range.

4. Green light and buzzer indicate

that the total resistance is either

less than 10MΩor less than

35MΩ.

Green = OK

You may now enter the EPA.

5. A red light indicates non-

conformance.

Red = FAIL

Do not proceed in the usual

manner but contact your

supervisor or follow your company

procedure.

6. Contact your supervisor if the

battery low light comes on.

Procedure to test wrist strap

1. Wear wristband. Choose one that

fits snugly or adjust it to do so.

2. Connect the ground cord securely

to the band using the snap

connector.

3. Connect the other end of the cord

to a matching termination on the

tester.

TECHNICAL BULLETIN TB-7536

Made in Britain