DESCO EUROPE - 2A DUNHAMS LANE, LETCHWORTH, HERTFORDSHIRE, SG6 1BE, UK

TB-7572 Page 3 of 3 © 2018 DESCO INDUSTRIES INC

Employee Owned

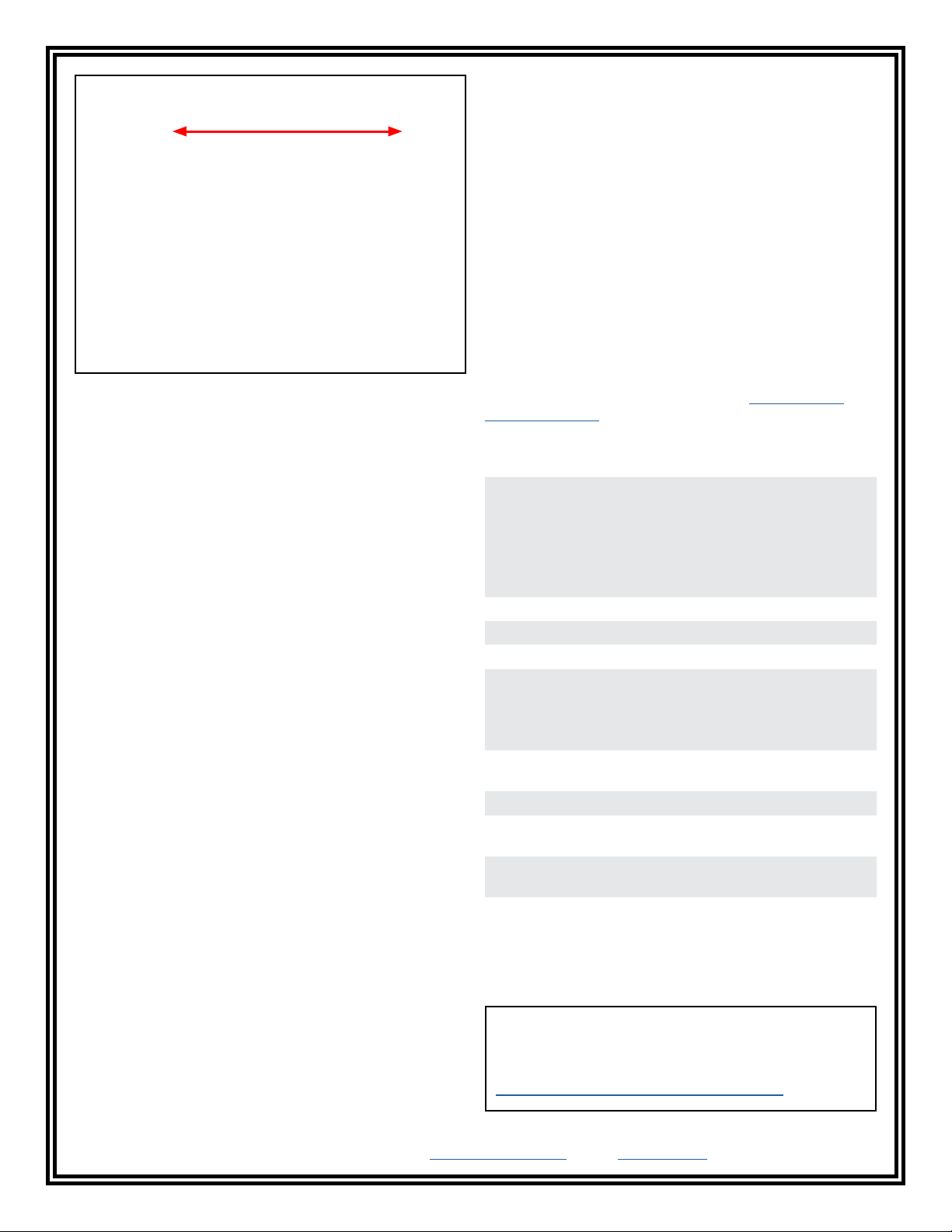

25 cm

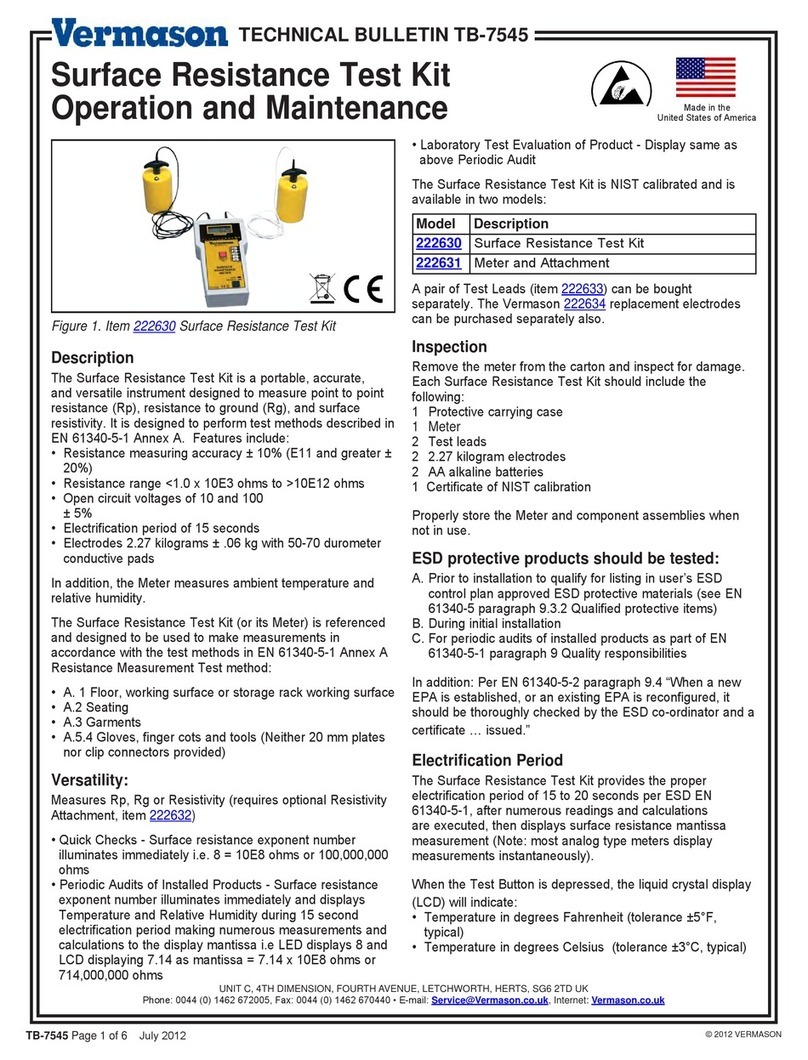

Figure 4. Using the test leads and two 2.27 kg electrodes

to measure Rp-p of worksurfaces (place electrodes 1 m

apart for ooring)

RECOMMENDED FREQUENCY OF PERIODIC

COMPLIANCE VERIFICATION OF INSTALLED

PRODUCTS

The ESD Association lists test procedures and

troubleshooting tips in Compliance Verification ESD TR53.

NOTE: “The frequency of periodic testing is normally

specified in corporate operating procedures. …The frequency

of testing is driven by the amount of risk exposure that can

occur between tests. For example, what is the quantity of

product handled between test periods?” (See ESD Handbook

ESD TR20.20)

A GUIDE FOR PERIODIC TESTING

• Worksurface, Carts, Shelves - at least quarterly (see ESD

TR20.20 section 5.3.1.13 Periodic Tests)

• Footwear - “Incoming inspection on a lot sampling basis

should be performed for all static control footwear.” (see

ESD TR20.20 section 5.3.3.4 Testing)

• Floor - “In some cases, a simple electrical resistance

test with a megohmmeter may suffice. In others, a static

charge generation test may be required. The frequency of

testing is also a consideration. Some materials, such as

floor finishes, may require more frequent testing because

of their lack of permanency.” (see ESD TR20.20 section

5.3.4.15.1.4)

• Seating - “The recommended electrical resistance range

for seating is less than E9 ohms as tested in accordance

with ANSI/ESD STM 12.1. This value should be during

acceptance testing, installation and periodically thereafter.”

(see ESD TR20.20 section 5.3.5.3 Testing)

• Garments - “ESD TR53 describes periodic verification test

methods and trouble shooting for garments. The sleeve to

sleeve resistance test should be made to ensure proper

resistance range through the entire garment. Alternately,

the garment while worn can be tested using a wrist strap

tester.” (ESD Handbook ESD TR20.20-2008 section

5.3.13.3.1.7 Periodic Verification Testing)

Maintenance

The area surrounding the cable jacks at the top end of the

meter should be wiped with a clean cloth moistened with

alcohol to remove skin oils that will accumulate and affect the

accuracy at high resistances. The frequency of cleaning will

depend on usage; once a month would be a good starting

point.

Clean the electrodes with a minimum 70% isopropanol-water

solution. Make sure conductive pads are dry prior to use.

The Analogue Surface Resistance Meter requires little

maintenance, and there are no user serviceable parts. If

your unit requires service beyond cleaning the electrodes

or replacing the batteries, please contact Desco Europe

Customer Service.

Limited Warranty, Warranty Exclusions, Limit

of Liability and RMA Request Instructions

See the Desco Europe Warranty -

DescoEurope.com/Limited-Warranty.aspx

Specications

Resistance Ranges 1 x 103to 1 x 1013 ohms @

10 Volts, complies with IEC

61340-2-3

1 x 106to 1 x 1013 ohms @

100 Volts, complies with IEC

61340-2-3

Accuracy ±1/2 decade

Power Supply 9 V alkaline battery

Operating Temperature 41 ºF to 85 ºF (5 ºC to 30 ºC)

Environmental

Requirements

Indoor use only at altitudes

less than 6500 ft. (2 km)

Maximum relative humidity of

80% up to 85 °F (30 °C)

Meter Dimensions 4.5" x 2.8" x 2.1"

(11 cm x 7 cm x 5 cm)

Meter Weight 0.5 lbs (0.2 kg)

Carrying Case Kit

Dimensions

9.5" x 12.0" x 3.5"

(24 cm x 30 cm x 9 cm)

Carrying Case Kit

Weight

12.0 lbs (5.4 kg)

External Electrode 5 lbs (±2 oz), 2.5"

(2.27 kg [±0.06 kg], 6.35 cm)

in diameter complies with IEC

61340-2-3