BEFORE INSTALLING THIS LIFT:

Verify that this product and its installation does not violate

local building codes. Youcan find out this information

from a local building inspector, architect, structural

engineer, or your buildingcontractor.

Find out if there are any code restrictions on what types

of things you can store in your attic.

Getprofessional adviceand estimates onframing,

decking and assembly if you are not qualified or

physically able to do these tasks. You can find building

contractors, remodeling contractors, architects,

engineers and inspectors in the Yellow Pages.

Youareresponsiblefordeterminingthesuitabilityofthis

product for your individual purposes, as well as installing

itin a waythat meetslocal building andsafetycodes.

Two persons are required to

perform certain tasks in this guide for safer and

easier installation. Performing these tasks alone is

not recommended.

Versa Lift

INSTALLATION OVERVIEW:

1.

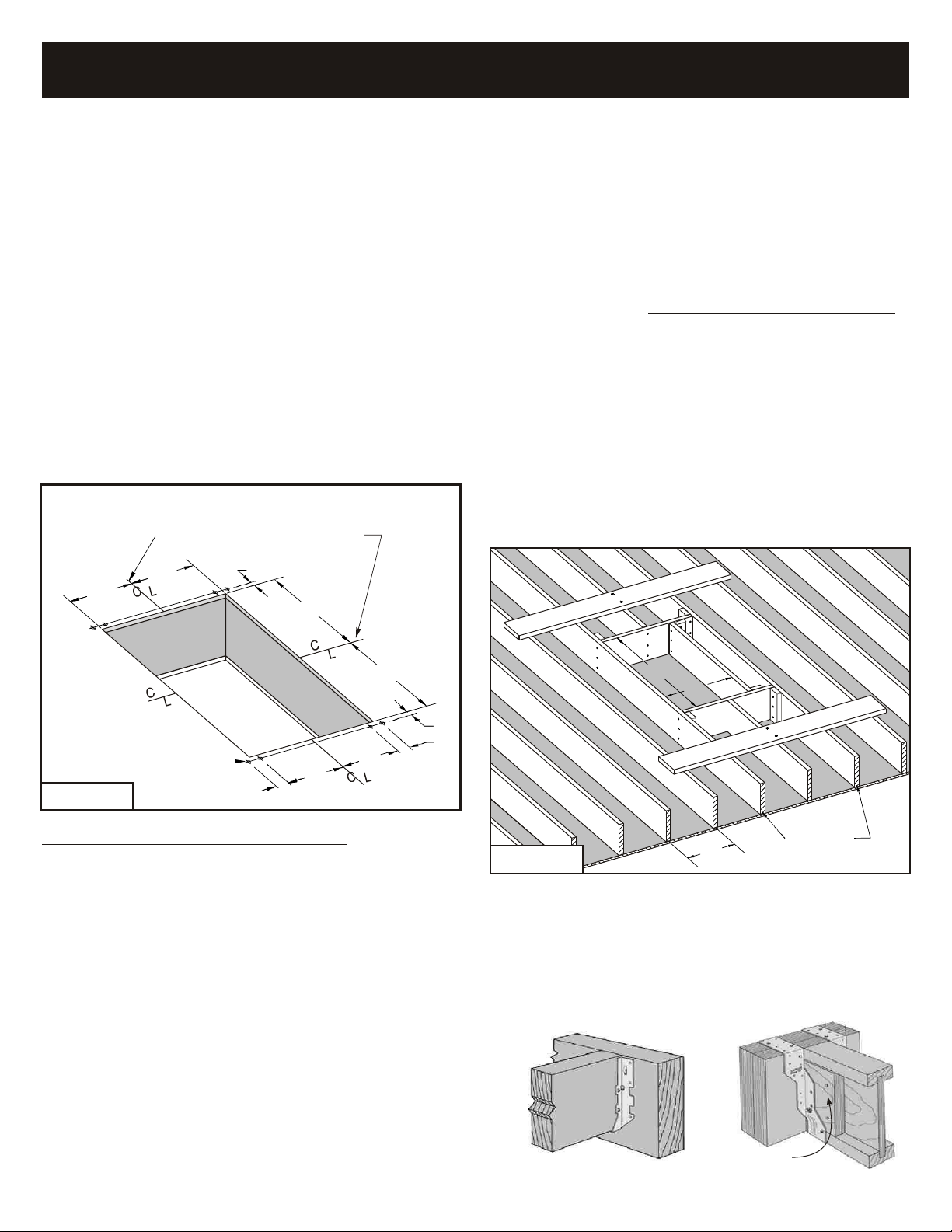

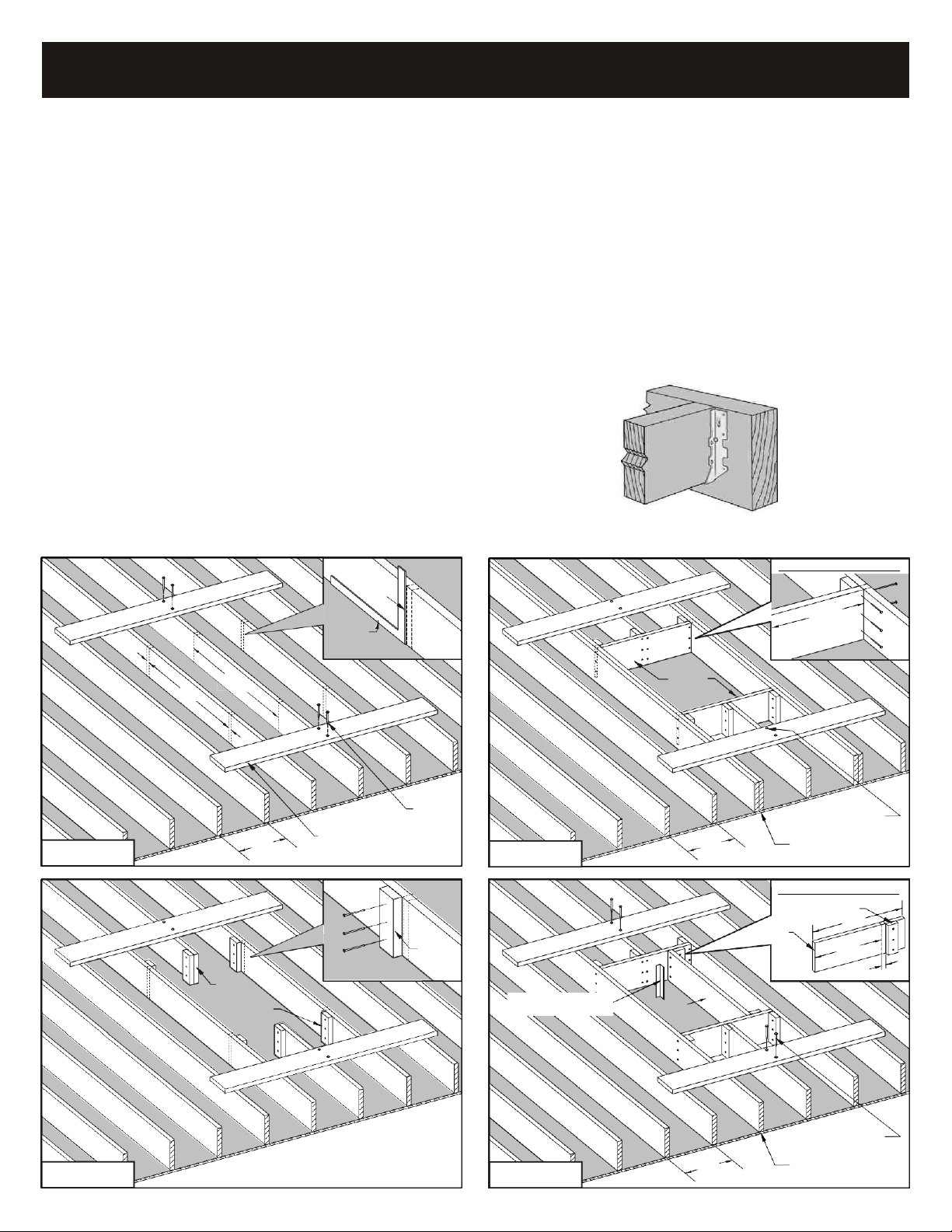

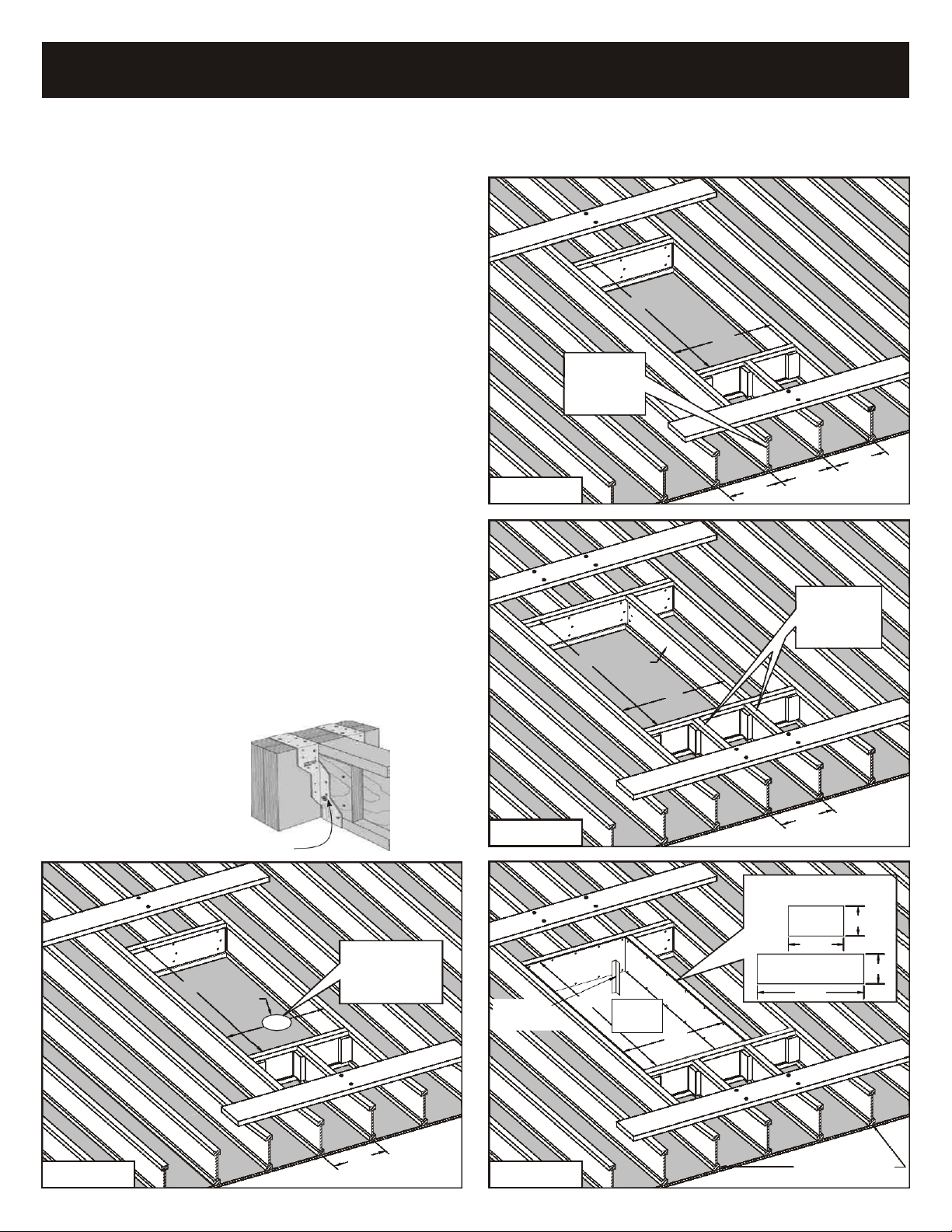

FRAME THE OPENING:

The first step to installing your new Versa Lift is preparing

an opening in the ceiling wheretheliftwill belocated.

Tools/Materials Required: Saws, Drill-Driver, Hammer,

Nails or Screws, Framing Square, Tape Measure, Header

& Joist Lumber to match your existing joists.

Skill Level: Professional - Only attempt this part of the

installationyourselfifyouareskilledinconstruction-type

framing.Ifyouarenot,youshouldhireaVersaLiftdealer

or a building/remodeling contractor to do this job for you.

Before cutting any ceiling joist, consult a contractor or

structural engineer to determine the best location to

install your lift. Also, if your attic is not already decked,

get some advice on the best areas to add decking in your

attic for storage.

2.

FLOORING AN ATTIC SPACE:

If your attic is not already floored in the area where your

Versa Lift will be installed, then flooring material such as

plywoodmust be addedontopof the ceiling joiststo

makea floor thatyoucan walkon andstoreitemson.

Tools/Materials Required: Skill Saw, Hammer and Nails

or Screws and Power Driver, Framing Square, Tape

Measure, and Decking Material.

Skill Level: Handyman - If you have skill with general

carpentry tools (sawing, measuring, nailing or screwing)

and the physical strength to move large pieces of wood,

then you can do this part yourself with a helper.

(

You can

get 4 x 4-ft. or 2 x 8-ft. pre-cut plywood at most lumber

stores. It is much easier to handle than 4 x 8-ft sheets.)

3.

ASSEMBLE AND INSTALL THE LIFT:

The Versa Lift comes partially assembled. The cartons

contain all of the parts and fastening hardware, along

with detailed instructions in this guide for assembly.

Tools/Materials Required: A Power Drill-Driver, 5/32”

Drill Bit, Phillips Driver Bit, Socket Driver Bit, Tape

Measure, Square, Level, Phillips Screwdriver, 3/8” & 7/16”

Wrenches, and 3/8” & 7/16” Sockets and Ratchet.

Skill Level: Handyman - If you have the skill for general

repair and maintenance using hand tools and can read

and follow instructions, then you can do this part yourself

with a helper.

VERSA LIFT SPECIFICATIONS:

General Specifications (All Models 32)

Dimensions 34W x 69L x 60H

Vertical Attic Space Req’d. 60” Min.

Max. Joist Height 18”

Lift Opening Size 30.5 x 58.5”

Motor 0.6 hp

Voltage

120 VAC

Power 5 amps

Lift Capacity Max.

250 lbs.

Lifting Speed

8 in/sec

DutyCycle(minutes) 2 on / 4 off

Lifting Cables (2) .093 (7x19)

Shipping Wt. (approx) 220 lbs.

Model Floor-to Floor

32......................................................................8-11 ft.

32H..................................................................11-14 ft.

32HX...............................................................14-17 ft.

32HXX.............................................................17-20 ft.

Control Options

Handheld Remote...............(keylock and 15-ft cord)

Wall Mounted Switch Set....(downstairs has keylock)

Wireless Remote........(with powerful Radio Receiver)