BC-1280-2 Lower Boom Rest 107.....................................................................................

BC-1341-6 10 Ft Elevator Auto Latch Installation 108.......................................................

CA-1280-23 Capacity Option 1000 lb Jib & Winch w/ Lift Elevator 109...............................

CC-1280-11 Airline Installation Truguard on Lift Elevator 110.............................................

DE-1280-28 Decal Kit 4-Axis Upr Ctrls Truguard Single Tool w/Jib & Winch

on Single Lift Elevator 111.............

DE-1280-29 Decal Placement w/Jib & Winch on Single Arm Lift Elevator 112...................

DE-1341-5 Decal Placement for Single Arm Lift Elevator 113...........................................

DE-1400-15 Decal Kit 1 Set Out & Down 2 Spool w/Interlock 114......................................

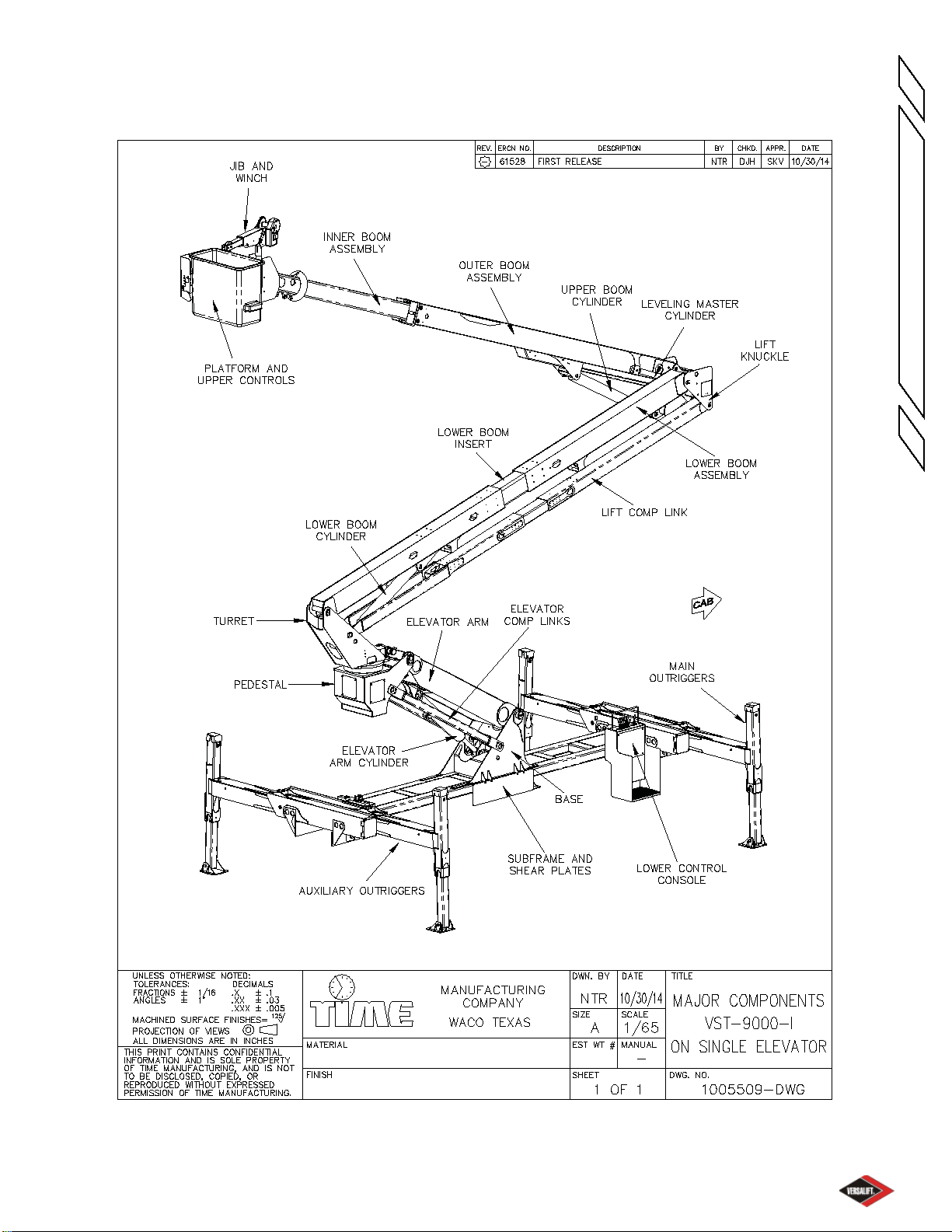

E-1341-5 10 Ft Single Arm Lift Elevator Assembly 115..................................................

EP-1340-4 Emergency Power Insulated 12 VDC 116.......................................................

ET-1280-1 Electrical Test Bands 117................................................................................

FB-1500-6 Platforms 118..................................................................................................

HK-1280-49 Hydraulic Jib Truguard Hose Kit 119...............................................................

HK-1280-69 Lower Boom Hose Kit w/ Jib Winch on Single Lift Elevator 120......................

HK-1280-71 Inner Boom Hose Kit w/ Jib Winch on Single Lift Elevator 121.......................

HK-1280-72 Upper Control Hose Kit Truguard on Single Lift Elevator 122.........................

HK-1280-77 Single Arm Lift Elevator Hose Kit 10 Ft Elevator w/ Jib & Winch 123.............

HYD-1280-12 Tank Line Relief Installation 124.....................................................................

HYD-1280-14 Lower Control Console 125.............................................................................

HYD-1280-2 Cylinders 126...................................................................................................

HYD-1340-14 Chassis Hydraulics for Elevator 127................................................................

IB-1280-32 Inner Boom Assembly w/ Test Band Lift Elevator 128....................................

JW-1270-15 Jib & Winch 129...............................................................................................

KN-1280-1 Knuckle Assembly 130....................................................................................

LB-1280-4 Lower Boom Assembly 131.............................................................................

LT-1260-4 Lift Throttle Insulated 132................................................................................

MH-1280-19 Upper Boom Tip Rest 133...............................................................................

MH-1280-5 Upper Boom Rest Install - Turret Mounted 134...............................................

MH-1280-7 Upper Boom Rest Installation 135...................................................................

MH-1400-23 Out and Down Outrigger Mounting Hardware 136..........................................

MH-1400-23 Out and Down Outrigger Mounting Hardware 137..........................................

OB-1280-4 Outer Boom 138..............................................................................................

OR-1400-60 Out and Down Outrigger Assembly Track Vehicle 139...................................

OR-1400-60 Out and Down Outrigger Assembly Track Vehicle 140...................................

PS-1280-2 Platform Support Assembly For Jib And Winch 141........................................

PS-922 Platform Support 142.......................................................................................

RO-1280-3 Continuous Rotation 20 Pass Single Lift Elevator 143....................................

RP-1200-4 Rope Assembly 144........................................................................................

SC-1280-50 4-Axis RH Truguard Ipper Controls w/ Hydraulic Jib & Winch

Single Tool on Single Lift Elevator 145.............

SD-1200-13 Slope Indicator Installation 146.......................................................................

SS-60 Master Switch & Start/Stop 12V 147...............................................................

TT-1280-4 Turret Assembly Lift Elevator 148...................................................................

VK-1400-27 2 Sets Out & Down (4 Spool w/ Switch) 149...................................................

VK-1400-30 Dual Out and Down Interlock Kit 150..............................................................

VK-1400-32 12V Outrigger/Lower Boom Interlock 151.......................................................

Options Option List OptionList......................................................................................